High Density Pond Liner

High density pond liner is frequently made of immoderate density polyethylene (HDPE), a lengthy lasting and impermeable geomembrane designed for long-term water retention in ponds, reservoirs and extraordinary water storage applications. Its sturdy mechanical properties and resistance to UV rays, chemical elements and environmental stresses make it a preferred reply for water administration in aquaculture, agriculture and industry.

- Thickness: 0.5 mm to three mm, customizable primarily based on mission needs

- Roll Width: Up to eight meters, lowering seams and simplifying installation

- Color: Standard black for optimum UV protection; customized hues accessible on request

- Tensile Strength: ≥ 25 MPa (varies by using thickness )

- Elongation at Break: ≥ 700%, presenting first-rate flexibility

- Density: Approximately 0.94 g/cm³

1. High Density Pond Liner

A High Density Pond Liner is a durable, impermeable geomembrane made principally from High-Density Polyethylene (HDPE). It is designed for long-term containment of water in ponds, reservoirs, aquaculture systems, and industrial lagoons. Its first-rate mechanical properties, environmental resistance, and ease of set up make it a favored desire for engineers and undertaking managers in each environmental and water infrastructure applications.

2. High Density Pond Liner – Key Advantages at a Glance

2.1 High Impermeability

High density pond liner structure a notably fantastic barrier that prevents water and different beverages from leaking through. Their ultra-low permeability ensures extraordinary water retention, decreasing loss and preserving steady water tiers even in traumatic applications.

2.2 UV & Weather Resistant

Designed to stand up to extended publicity to daylight and harsh weather conditions, High density pond liner face up to degradation precipitated by using UV radiation, temperature fluctuations, rain, and wind. This sturdiness makes them perfect for long-term out of doors pond installations except compromising performance.

2.3 Chemical Resistant

High density pond liner is chemically inert and fairly resistant to a wide spectrum of industrial and agricultural chemicals, such as acids, alkalis, fertilizers, and pesticides. This resistance protects the liner from corrosion and ensures protected containment of probably dangerous substances.

2.4 Puncture & Tear Resistant

Thanks to their excessive tensile power and sturdy molecular structure, High density pond liner can suffer sharp objects, difficult subgrades, and heavy masses besides tearing or puncturing. This longevity minimizes the threat of injury throughout set up and during the liner’s carrier life.

2.5 Environmentally Safe

Our High density pond liner is made from non-toxic substances that are secure for aquatic life, making them perfect for fish farms, shrimp ponds, and different aquaculture applications. They do no longer leach damaging resources into the water, assisting preserve a wholesome ecosystem.

2.6 Flexible & Weldable

Despite their strength, High density pond liner continue to be bendy sufficient to be fashioned to complicated pond contours. They can be without difficulty welded on-site to create seamless, leak-proof joins and repaired shortly if needed, lowering set up time and cost.

2.7 Long Service Life

Under optimum conditions, High density pond liner provide an remarkable lifespan of up to 30 years. Their resistance to environmental elements and mechanical stresses ensures reliable, maintenance-free overall performance over decades, making them a most economical investment.

3. High Density Pond Liner Technical Specifications

3.1 Common Thickness Options

0.2mm,0.5 mm, 0.75 mm, 1.0 mm, 1.5 mm, two mm, up to three mm

(thickness chosen based totally on utility load and website condition)

3.2 High Density Pond Liner Dimensions

- Width: Up to eight meters

- Length: Customized roll lengths for effortless handling

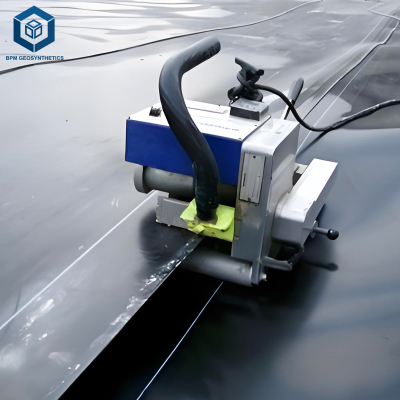

3.3 Welding & Seaming

- Thermally welded the use of wedge welders or extrusion welders

- Seam testing: Peel and shear power assessments performed per challenge standards

4. High Density Pond Liner Features

4.1 Material Properties

Our high density pond liner is made from excellent virgin HDPE resin, making sure constant power and durability. They provide fantastic chemical resistance in opposition to acids, alkalis, and hydrocarbons, and are UV stabilized for dependable long-term out of doors performance.

4.2 Structural Advantages

These liners supply first-rate tensile strength, successfully resisting stress and elongation at some stage in set up and use. They are rather resistant to punctures and tears, making them appropriate for difficult or rocky subgrade conditions. Additionally, they can be seam-welded the use of thermal strategies to create secure, watertight joints.

4.3 Environmental Compatibility

High density pond liner is one hundred percent non-toxic and secure for aquatic ecosystems. They meet worldwide environmental requirements such as ASTM and GRI-GM13, making them appropriate for each potable and non-potable water containment applications.

5. Applications of High Density Pond Liner

5.1 Aquaculture Ponds

High density pond liner furnish a reliable, non-toxic barrier that helps preserve easy and steady water stipulations vital for fish and shrimp farming. Their chemical resistance ensures safety from contamination, whilst their impermeability prevents water loss, helping healthful aquatic ecosystems and optimum increase conditions.

5.2 Irrigation and Agricultural Reservoirs

Used notably in agricultural settings, these high density pond liner limit water seepage, conserving precious water resources. Their long lasting building helps large-scale irrigation reservoirs, enabling environment friendly water storage and distribution whilst defending surrounding soil from saturation and erosion.

5.3 Industrial Wastewater Lagoons

High density pond liner is best for containing industrial effluents, together with hazardous and chemical-laden wastewater. Their chemical inertness prevents liner degradation and leachate escape, making sure secure storage and compliance with environmental rules in remedy lagoons and containment basins.

5.4 Landfill and Environmental Containment

Serving as a imperative factor in landfill design, High density pond liner structure a low-permeability barrier that successfully prevents leachate migration. This containment reduces soil and groundwater illness risks, assisting landfill operators in assembly strict environmental safety standards.

5.5 Decorative and Landscape Ponds

Beyond practical uses, High density pond liner is famous in landscaping for developing captivating water elements in gardens, parks, and golf courses. Their flexibility approves set up in complicated shapes, whilst their sturdiness ensures long-lasting overall performance with minimal maintenance.

6. High Density Pond Liner Frequently Asked Questions

6.1 Q1: What makes excessive high density pond liner higher than common clay or concrete?

A1: High density pond liners are greater cost-effective, faster to install, and extra impermeable than typical materials. They additionally require much less renovation and are greater resistant to cracking, weathering, and chemical degradation.

6.2 Q2: Is High Density Pond Liner protected for aquaculture and ingesting water?

A2: Yes, amazing high density pond liners are licensed non-toxic, free from hazardous additives, and secure for use with fish, shrimp, and even potable water, relying on the product grade.

6.3 Q3: How lengthy does a excessive density pond liner last?

A3: With perfect set up and publicity conditions, high density pond liners can final 20 to 30 years or more, in particular when UV-protected and used in protected or submerged environments.

6.4 Q4: Can the High Density Pond Liner be repaired on-site if damaged?

A4: Yes, high density pond liners can be patched or welded on-site the use of splendid tools. Seam and patch integrity can be examined to make certain water tightness after repairs.

About BPM GEOSYNTHETICS

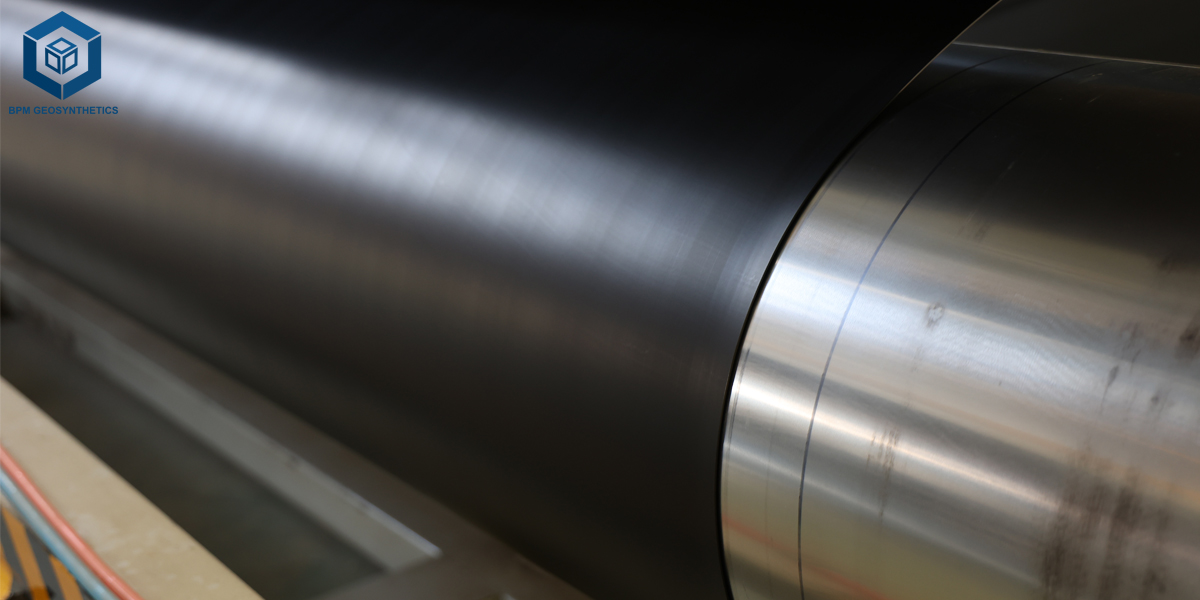

BPM GEOSYNTHETICS is a depended on producer of high-performance HDPE pond liners, serving international customers throughout aquaculture, agriculture, environmental engineering, and industrial sectors. With a contemporary manufacturing facility masking over 360,000 rectangular meters, BPM operates multiple superior HDPE geomembrane manufacturing lines, succesful of manufacturing liners in a number of thicknesses (0.5mm–3mm) and widths up to eight meters.

Our manufacturing unit makes use of 100% virgin HDPE resin, making sure most appropriate durability, chemical resistance, and long-term impermeability. Each product undergoes strict first-class manage procedures, along with tensile strength, puncture resistance, elongation, and permeability testing, all in compliance with global requirements such as ASTM, GRI-GM13, and ISO.

BPM presents custom fabrication services, on-time delivery, and full technical help from cloth determination to on-site set up guidance. As a direct manufacturing facility provider with over 15 years of experience, we are dedicated to turning in cost-effective, environmentally safe, and dependable lining solutions for traumatic water containment applications.