LLDPE Geomembrane Liner

LLDPE geomembrane liner is a flexible and durable lasting barrier broadly used in environmental functions to manipulate fluid motion. These liners are famend for their exceptional elongation overall performance and puncture resistance, making them an best desire for a number sealing projects, consisting of landfills, reservoirs, and mining operations.

-High puncture resistance : Its sturdy shape has terrific puncture resistance and tear resistance, making sure long-lasting performance.

-Chemical resistance : LLDPE geomembrane liner can successfully stand up to a vary of chemicals, making them appropriate for a variety of industrial applications.

-UV balance : These LLDPE geomembrane liner are cautiously designed to withstand degradation from UV publicity and keep their integrity over time.

LLDPE geomembrane liner is an superior artificial movie designed especially for a number of environmental manage applications. LLDPE geomembrane liner is famend for its splendid flexibility and strength, making it best for initiatives that require dependable fluid sealing, such as landfills, ponds, reservoirs, and mining operations.LLDPE geomembrane liner is manufactured via a manner that enhances its molecular shape and has amazing elongation ability, permitting it to adapt to uneven surfaces and a number shapes. This adaptability is critical for making sure protected set up in one of a kind set up eventualities and can decrease the hazard of leakage.

LLDPE geomembrane liner presents an high quality answer for environmental protection, providing a aggregate of flexibility, strength, and chemical resistance to meet the numerous wishes of modern-day containment projects. Their reliability and overall performance make them an essential issue of sustainable waste administration and useful resource conservation efforts.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | D1505/D792 | 90.000kg | 0.94g/cc | ||||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 5 3 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

LLDPE Geomembrane Liner Features

1. High flexibility : LLDPE geomembrane liner has high flexibility, permitting it to without problems adapt to more than a few shapes and contours, making it convenient to set up in difficult terrains.

2. Excellent puncture resistance : These LLDPE geomembrane liners are designed to stand up to punctures and tears, making sure sturdiness and reliability in harsh environments and lowering the danger of leakage.

3. Chemical resistance : LLDPE geomembrane liner has robust resistance to more than a few chemicals, such as acids, alkalis, and natural solvents, making it appropriate for industrial and agricultural applications.

4. UV steadiness : The LLDPE geomembrane liner is cautiously designed to face up to degradation through ultraviolet (UV) radiation and keep its structural integrity and overall performance beneath extended daylight exposure.

5. High elongation performance: These LLDPE geomembrane liner have good sized elongation potential and can stretch besides breaking, offering extra security and stopping stress and motion in the underlying substrate.

6. Cost effectiveness: LLDPE geomembrane liner is an economically environment friendly fluid sealing answer that strikes a stability between pleasant and affordability, appropriate for quite a number projects.

7. Smooth surface : The smooth surface of LLDPE geomembrane liner reduces friction and enhances flow characteristics, which is really useful in purposes such as water retention and drainage systems.

8. Environmental Compliance : LLDPE geomembrane liners assist meet regulatory necessities for environmental safety and forestall soil and groundwater air pollution in waste administration applications.

Applications of LLDPE Geomembrane Liner

1. Landfill Site : LLDPE geomembrane liner is broadly used as a liner for landfills to stop leachate from contaminating the surrounding soil and groundwater, making sure environmental protection.

2. Ponds and reservoirs: These liners are ideal for constructing impermeable limitations in storage ponds and reservoirs, assisting to reduce water loss induced by using leakage.

3. Mining operation : During the mining process, LLDPE geomembrane liner is used to incorporate hazardous materials and control tailings, decreasing environmental have an impact on and making sure protected disposal.

4. Agricultural Applications : LLDPE geomembrane liners are used in agricultural environments to manipulate runoff, stop soil air pollution from pesticides and fertilizers, and promote sustainable agricultural practices.

5. Wastewater treatment: These geomembranes are used in wastewater cure amenities to lay ponds and swimming pools to stop pollution from getting into groundwater.

6. Control of Hazardous Substances: LLDPE geomembrane liner presents an fantastic barrier for storing and controlling hazardous elements in industrial environments, making sure security and compliance with regulations.

7. Bioreactor landfill site: In the bioreactor landfill system, LLDPE geomembrane liners assist manipulate leachate flow, promote anaerobic digestion, beautify waste decomposition and power recovery.

8. Construction challenge : These LLDPE geomembrane liners are used for a variety of constructing applications, along with conserving partitions and erosion control, to supply waterproofing and stability.

These purposes display the versatility and effectiveness of LLDPE geomembrane liner in defending the surroundings and managing fluids in unique industries.

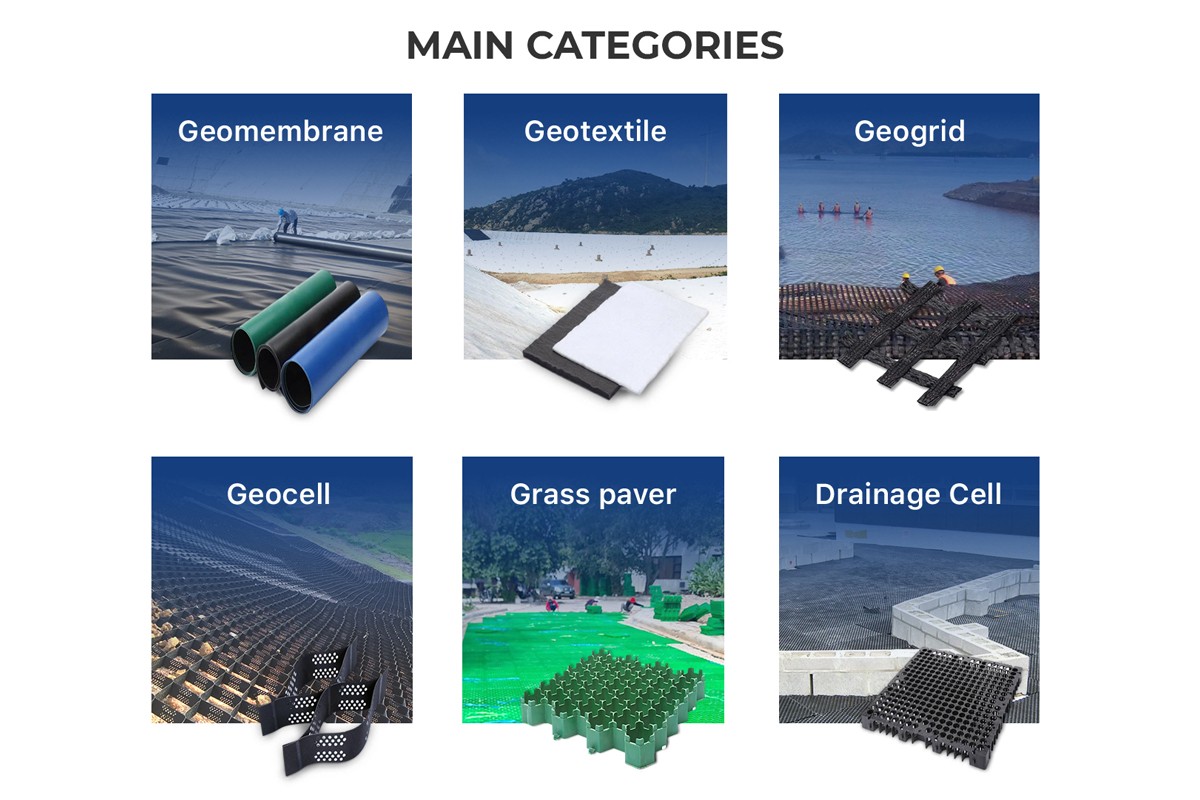

Company Profile

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a leading manufacturer and exporter of high-quality geosynthetic products, including geomembranes, geotextiles, geogrids, geocells, and geosynthetic clay liners (GCL). Our products, certified by EU CE and GLP, have passed ISO 9001, ISO 14001, and OHSAS 18001 standards, and are recognized for their quality, performance, and durability.

BPM GEOSYNTHETICS has been committed to providing one-stop services for global customers in the research and development, production, sales, and export of geosynthetic materials since its establishment in 2007. The company has 120 senior technical talents specializing in geotechnical materials. The manufacturing factory covers an area of over 36000 square meters and is equipped with industry-leading automated production equipment and professional testing instruments. Product innovation, quality assurance, and customer satisfaction have always been BPM commitment to partners.

We're committed to innovation and quality, offering flexible cooperation and the best solutions for engineering projects worldwide. Our products are utilized in various sectors like aquaculture, erosion control, drainage systems, municipal engineering, mining, and landscaping. We look forward to partnering with you to solve complex challenges with our high-performance geosynthetic products.