Geotech Road Fabric

BPM Geotech Road Fabric is engineered to grant best soil separation, stabilization, and drainage in avenue construction, driveways, and civil engineering projects. Manufactured from high-strength artificial fibers, it affords brilliant load-bearing capability and resists harm from set up stresses, making sure long-lasting overall performance below heavy visitors conditions.

- High Tensile Strength – Withstands heavy masses and site visitors barring tearing or deforming.

- Excellent Soil Separation – Prevents intermixing of subgrade soil and aggregates, preserving street integrity.

- Enhanced Load Distribution – Reduces rutting and floor deformation for longer street life.

- Superior Drainage Capability – Allows water to ignore whilst preserving soil, stopping erosion.

- UV & Chemical Resistance – Suitable for long-term out of doors publicity and harsh environments.

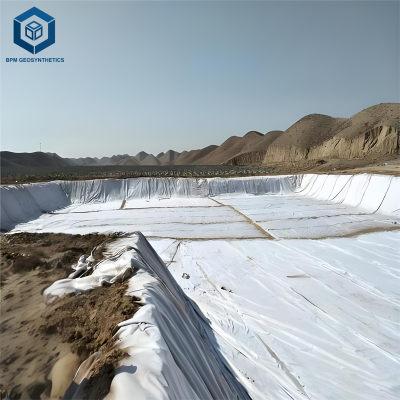

Geotech Road Fabric is a specialised geotextile fabric designed to decorate the strength, stability, and sturdiness of roadways, driveways, parking lots, and different paved or unpaved surfaces. Made from tremendous polypropylene or polyester fibers, the fabric is engineered to furnish tremendous soil separation, load distribution, and drainage performance. Its strong shape ensures that it withstands excessive site visitors loads, environmental stress, and long-term publicity to UV rays and chemicals.

1. Geotech Road Fabric Material Composition & Manufacturing

BPM Geotech Road Fabric is manufactured the usage of superior needle-punching or weaving applied sciences to gain the ultimate stability of strength, durability, and filtration properties. They are on hand in each woven geotextile and nonwoven geotextile types, permitting engineers to pick out the pleasant alternative for precise floor prerequisites and overall performance requirements.

1.1 Woven Geotech Road Fabric:

- Made through interlacing high-strength artificial fibers in a precise, uniform pattern.

- Provides magnificent tensile energy and low elongation, making it best for heavy-load purposes such as highways, industrial yards, and airport runways.

- Excellent soil stabilization performance, efficiently stopping base cloth loss and retaining load distribution below intense site visitors pressure.

- Highly resistant to UV exposure, chemical degradation, and mechanical harm throughout installation.

1.2 Nonwoven Geotech Road Fabric:

- Produced the usage of a needle-punching process, growing a dense, third-dimensional fiber network.

- Offers terrific filtration and drainage capacity, permitting water to bypass whilst maintaining soil particles—perfect for tasks in areas with excessive groundwater or rainfall.

- Flexible and conformable, making it appropriate for uneven terrain and tender floor stabilization.

- Provides proper puncture resistance and long-term overall performance in erosion manage and subgrade reinforcement.

2. Geotech Road Fabric Key Functions

2.1 Geotech Road Fabric - Soil Separation

Creates a barrier between the subgrade soil and the mixture layer, stopping them from mixing over time. This separation helps hold the designed thickness and grading of the avenue base, making sure long-term balance and decreasing preservation needs.

2.2 Geotech Road Fabric - Load Support

Evenly distributes the weight of cars and heavy tools throughout the surface, minimizing stress points. This prevents rutting, sinking, and floor deformation, specifically on smooth or unstable floor conditions.

2.3 Geotech Road Fabric - Drainage

Allows rainwater and groundwater to ignore thru the material whilst preserving soil particles. This managed water waft prevents the buildup of hydrostatic pressure, reduces erosion, and improves avenue security by using retaining a steady subgrade.

2.4 Geotech Road Fabric - Reinforcement

Strengthens vulnerable soils by using enhancing their load-bearing capacity. The geotextile material acts as a stabilizing layer that helps building hundreds and traffic, making it viable to construct long lasting roads on difficult soil stipulations except immoderate excavation or replacement.

3. Geotech Road Fabric Main Advantages

3.1 Geotech Road Fabric - High Tensile Strength & Durability

Engineered from top class artificial fibers, needle punched geotextile fabric can stand up to heavy visitors loads, set up stresses, and excessive environmental stipulations barring tearing or deforming. This electricity ensures long-term structural balance in stressful projects.

3.2 Geotech Road Fabric - Excellent Filtration & Permeability

The material lets in water to omit via whilst keeping soil particles, keeping the drainage feature of the base layers. This property helps forestall soil erosion, waterlogging, and untimely avenue deterioration, even in areas with excessive rainfall.

3.3 Geotech Road Fabric - Long-Term UV & Chemical Resistance

Specially handled fibers furnish notable resistance to ultraviolet radiation, oxidation, and chemical exposure. This makes the fabric geotextile perfect for out of doors use in warm climates, coastal areas, and web sites with probably corrosive soil or water conditions.

3.4 Geotech Road Fabric - Easy Handling & Installation

Lightweight but strong, Geotextile road fabrics are convenient to cut, transport, and role on-site. They are handy in a number of roll widths and lengths to swimsuit unique venture requirements, enabling quick and environment friendly set up with minimal labor.

3.5 Geotech Road Fabric - Cost-Effective Performance

By enhancing soil stability, extending street lifespan, and lowering the want for standard repairs, White geotextile fabric supply high-quality long-term value savings. Their sturdiness and multifunctional overall performance decrease each development and upkeep expenses.

4. Geotech Road Fabric Technical Specifications

4.1 Geotech Road Fabric Material: Polypropylene (PP) or Polyester (PET)

Manufactured from terrific artificial fibers, PP presents splendid chemical resistance and durability, whilst PET presents most excellent tensile energy and dimensional stability. Both substances are designed for long-term overall performance in stressful building environments.

4.2 Geotech Road Fabric Fabric Type: Woven / Nonwoven

Woven fabric supply excessive tensile electricity and low elongation, perfect for load-bearing and reinforcement applications. Nonwoven fabric provide optimal filtration and drainage properties, making them appropriate for erosion manage and soil stabilization.

4.3 Geotech Road Fabric Tensile Strength: 8–200 kN/m (customizable)

Available in a broad vary of power scores to suit particular undertaking requirements, from light-duty landscaping to heavy-duty avenue and railway construction.

4.4 Geotech Road Fabric Weight: 100–1200 g/m²

Fabric density is customizable to supply the proper stability of strength, filtration capacity, and flexibility for special website conditions.

4.5 Geotech Road Fabric Width: 1–6 meters (customizable)

Multiple width preferences make certain environment friendly insurance with minimal seams, lowering set up time and workable susceptible points.

4.6 Geotech Road Fabric Roll Length: 50–100 meters (or customized)

Geotextile filter fabric standard roll lengths are designed for ease of dealing with and transportation, with customized choices handy for large-scale projects.

4.7 Geotech Road Fabric Color: Black, White, or Customized

Black gives UV safety and blends with most soil conditions, whilst white is used for precise visibility or temperature manage requirements. Custom colours are accessible for specialised projects.

4.8 Geotech Road Fabric UV Resistance: ≥70% energy retention after five hundred hours of exposure

The road fabric geotextile keeps its mechanical residences even after extended solar exposure, making sure sturdiness and reliability for outside installations.

5. Geotech Road Fabric Applications

Geotech Road Fabric is versatile and play a vital position in improving the overall performance and lifespan of quite a number infrastructure projects. Their strength, filtration ability, and soil stabilization residences make them appropriate for a large vary of civil engineering and development applications.

5.1 Geotech Road Fabric for Road and Highway Construction

Used as a separation and reinforcement layer between the subgrade and mixture base, the cloth improves load distribution and prevents base cloth contamination.

- Example: In a current motorway enlargement project, woven geotextile was once mounted to stop rutting on smooth clay subgrades, lowering preservation charges over a 10-year period.

5.2 Geotech Road Fabric for Driveways and Parking Areas

Enhances floor stability, prevents gravel loss, and reduces weed growth, making sure a cleaner, longer-lasting surface.

- Example: A industrial parking lot in a coastal town used nonwoven geotextile for elevated drainage, stopping flooding at some stage in heavy rains.

5.3 Geotech Road Fabric for Railway Track Stabilization

Placed below ballast layers to stop soil migration whilst retaining appropriate drainage, extending tune carrier life.

- Example: A freight railway venture used woven geotextile to stabilize a area constructed over silty soil, lowering contract and tune deformation.

5.4 Geotech Road Fabric for Airport Runways and Taxiways

Provides reinforcement and separation in areas subjected to excessive wheel loads, making sure protection and performance.

- Example: An airport renovation task mounted high-strength woven geotextile below the runway base to cope with heavy plane hundreds barring structural failure.

5.5 Geotech Road Fabric for Rural and Forestry Roads

Strengthens low-volume roads constructed on susceptible soils, decreasing renovation frequency and enhancing accessibility.

- Example: Forestry carrier roads in mountainous terrain had been strengthened with geotextile, permitting year-round automobile get entry to no matter seasonal rain.

5.6 Geotech Road Fabric for Coastal Protection and Erosion Control Projects

Acts as a filtration and stabilization layer in seawalls, breakwaters, and embankments, stopping soil loss whilst permitting water movement.

- Example: In a shoreline stabilization project, nonwoven geotextile used to be positioned below riprap to shield towards wave-induced erosion.

6. BPM Geotech Road Fabric Quality Assurance

Every batch of BPM Geotech Road Fabric is examined for tensile strength, puncture resistance, elongation, and permeability to meet global requirements such as ISO, ASTM, and EN. Our strict first-rate manipulate device ensures constant overall performance and dependable consequences for each and every project.

BPM Geosynthetics has been a depended on identify in the geosynthetic enterprise for decades, imparting exceptional avenue fabric to clients in over one hundred countries. Whether your task entails street construction, railway stabilization, coastal protection, or erosion control, BPM gives confirmed options that mix durability, performance, and cost-effectiveness.