Non Woven Geotextile Price

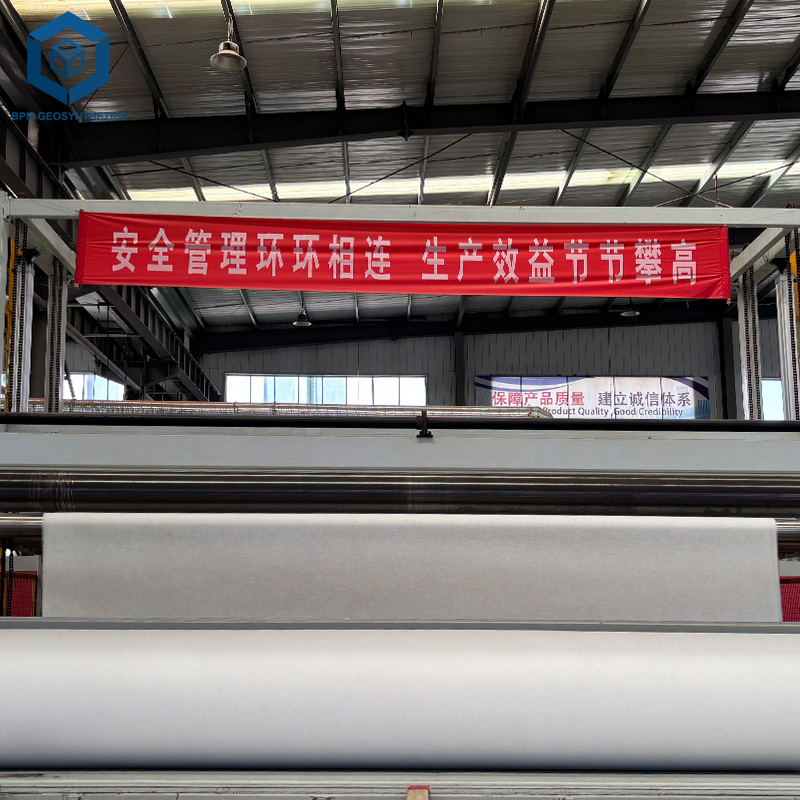

Non woven geotextile price depends on factors such as fabric weight, thickness, raw material quality, and application needs. Widely used in civil engineering and landscaping, non woven geotextile provides effective filtration, drainage, separation, and soil reinforcement. Its durability and cost-efficiency make it an economical choice for various construction projects.

- Fabric Weight (gsm):Higher GSM (100gsm–800gsm) increases strength and durability, resulting in a higher price.

- Polymer Grade:Prices differ between 100% virgin polypropylene/ polyester and recycled materials.

- Roll Size & Custom Specifications:Wider rolls, longer lengths, and customized dimensions typically cost more.

- Production Technology:Needle-punched and thermally bonded geotextiles have different performance levels and price ranges.

- Order Quantity:Larger bulk orders significantly reduce unit cost, making it more economical for infrastructure projects.

Non woven geotextile is an essential geosynthetic material widely used in civil engineering, road construction, drainage systems, and environmental protection projects. The non woven geotextile price is determined by several key factors, including fabric weight, polymer quality, production method, roll dimensions, and specific application requirements. Understanding these factors helps buyers choose the right product for performance and budget optimization.

1. Factors That Determine Non Woven Geotextile Price

1.1 Fabric Weight (GSM)

The most important factor affecting price is GSM (grams per square meter). Heavier fabrics use more raw material, which directly increases production cost.

- Lightweight (100–200gsm): Suitable for drainage and filtration; lower cost. Commonly used in landscaping and small-scale drainage systems where strength requirements are moderate.

- Medium Weight (200–400gsm): Ideal for separation, road construction, and slope protection. This category balances performance and affordability, making it popular for civil engineering projects.

- Heavy Duty (400–800gsm): Used for high-strength reinforcement, landfills, and demanding geotechnical works. These fabrics offer superior performance and durability for long-term infrastructure.

- Higher GSM = stronger performance = higher price. Heavier geotextile fabric generally deliver longer service life and better mechanical properties.

1.2 Material Quality

Prices vary significantly depending on raw materials. Higher-grade polymers offer increased structural integrity and aging resistance.

- 100% Virgin PP or PET: Highest quality and durability; premium price. These fabric geotextile materials provide excellent strength and consistent performance in harsh environments.

- Mixed or Recycled Material: Lower cost but reduced strength and lifespan. Suitable for temporary or low-load projects but not recommended for critical infrastructure.

- UV-Stabilized Material: Ensures longer outdoor durability, increasing cost slightly. UV additives protect the non woven geotextile fabric from sunlight degradation in exposed applications.

1.3 Manufacturing Technology

Production methods influence product performance and cost. The more advanced the process, the better the uniformity and mechanical properties.

- Needle-Punched Non Woven: Most common; excellent permeability and strength. The interlocked fibers create a durable geo fabric ideal for filtration and drainage applications.

- Thermally Bonded Non Woven: Smoother surface; higher mechanical strength; usually more expensive. This method enhances tensile strength and reduces fiber migration in demanding environments.

- Composite Geotextiles: Combined with geomembrane or geogrid; significantly higher price. These multi-layer systems provide enhanced barrier or reinforcement properties for specialized engineering projects.

1.4 Roll Dimensions

Non woven geotextile Roll size affects both material usage and handling efficiency. Larger rolls reduce jointing and installation time.

- Wider or Longer Rolls: Reduce installation time but increase cost. They minimize overlap waste and enhance site productivity, particularly in large areas.

- Customized Sizes: Slightly higher price due to adjusted production setup. Custom dimensions ensure precise fit for unique engineering designs or restricted installation spaces.

1.5 Order Quantity and Logistics

Bulk purchasing and shipping logistics play an important role in determining the final price. Larger orders typically lower the unit cost.

- Bulk Orders: Drastically reduce unit cost. Manufacturers offer discounts as higher volume improves production efficiency and reduces changeover time.

- Shipping Method: Sea, land, or container load also affects total cost. Freight charges, delivery distance, and container utilization all impact the final price paid by the buyer.

2. Key Performance Benefits of Non Woven Geotextile

2.1 Effective Filtration

Allows water to pass while preventing soil particles from migrating—critical for drainage systems, retaining walls, and subgrade stabilization.

This selective permeability ensures long-term soil structure stability and prevents clogging in drainage layers. Non woven landscape fabric also helps maintain consistent water flow, reducing pressure buildup in geotechnical structures.

2.2 Superior Drainage Capability

Non woven pores enhance water flow, reducing hydrostatic pressure and preventing erosion or foundation failure.

The interconnected fiber structure allows water to move freely across the non woven geotextile membrane plane, maintaining efficient drainage performance even under high loads. This helps extend the lifespan of roads, retaining walls, and water management systems.

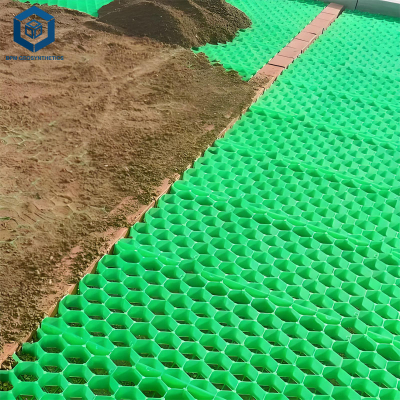

2.3 Soil Separation and Stabilization

Prevents the mixing of different soil layers, improving load distribution and preventing rutting in roads and driveways.

By creating a stable barrier between weak subgrade and aggregate layers, it enhances the structural integrity of pavements. This separation function reduces maintenance costs and increases project durability over time.

2.4 High Tensile Strength and Durability

Engineered to resist tearing, puncture, abrasion, chemical corrosion, and UV exposure (with additives).

These properties allow the geotextile drainage fabric to perform effectively under heavy loads, rough installation conditions, and challenging environments. Its durability ensures long-term reliability, even in aggressive soil or water conditions.

2.5 Long Service Life

Virgin-grade geotextile filter fabric can last 20–50 years depending on installation conditions.

Its resistance to biological and chemical degradation allows it to function reliably in buried or submerged applications. When properly installed, the geo textile material maintains its mechanical and hydraulic properties for decades.

3. Non Woven Geotextile is Cost-Effective

3.1 Reduces soil erosion and maintenance costs

By providing effective filtration and stabilization, geotextile drainage prevents soil displacement and sediment loss. This reduces the need for frequent repairs and long-term maintenance on slopes, drainage areas, and embankments.

3.2 Eliminates premature road damage

The geotextile filter cloth separates subgrade soil from aggregates, preventing rutting and deformation under traffic loads. This significantly extends pavement service life and reduces costly reconstruction work.

3.3 Improves load-bearing capacity without extra materials

Geo fabric cloth enhances soil structure, allowing it to carry heavier loads without adding thick layers of gravel or sand. This reduces geotextile material consumption and lowers overall project costs.

3.4 Easy to install, reducing labor expenses

Its lightweight and flexible structure allows for quick handling, cutting, and placement on-site. Faster installation reduces labor hours, increases project efficiency, and minimizes equipment requirements.

3.5 Resists degradation, extending project lifespan

The geo fabric material is engineered to withstand chemicals, moisture, and microbial attack, ensuring stable long-term performance. UV-stabilized grades also offer superior durability in exposed conditions.

3.6 Even higher-grade materials provide excellent long-term value

Although premium nonwoven geotextile fabric cost more upfront, their extended lifespan and improved performance reduce the total cost of ownership. This makes them a smart investment for large-scale or high-demand engineering projects.

4. Non Woven Geotextile Price – Expanded Q&A

Q1: What is the average price range of non woven geotextile?

The price typically ranges from $0.20–$1.50 per square meter, depending on GSM, raw material quality, and order quantity. Lightweight fabrics cost less, while heavy-duty grades used for high-strength reinforcement are priced higher.

Q2: Why do different GSM levels have different prices?

Higher GSM means more fiber content, thicker fabric, and greater strength, which directly increases production cost. Heavy-duty geotextiles also undergo stricter quality control, contributing to the higher price.

Q3: Are higher-priced non woven geotextiles worth it?

Absolutely. Premium-grade geotextiles offer better performance, lower maintenance, and longer service life. They reduce long-term project costs, especially in roads, drainage systems, and geotechnical engineering.

Q4: How does order quantity affect pricing?

Buying in bulk significantly lowers the unit price. Large orders reduce production changeover time and allow manufacturers to optimize material usage, resulting in cost savings.

Q5: How can I reduce the overall cost of purchasing geotextile?

You can lower cost by:

Choosing the appropriate GSM (not over-specifying)

Ordering full-container quantities

Using standard roll sizes

Selecting non-UV grades for buried installations

Working directly with manufacturers rather than traders

5. Choose the Right Non Woven Geotextile

Required GSM based on load and soil type: Choose GSM according to soil conditions and traffic load for proper strength and durability.

- Water flow rate and filtration needs: Ensure permeability meets drainage requirements and prevents soil migration.

- Expected lifespan and environmental exposure: Consider UV, chemical, and weather conditions to select long-lasting materials.

- Project scale and roll size requirements: Pick roll sizes that cover the area efficiently and reduce installation time.

- Budget vs performance balance: Weigh cost against durability and performance for optimal long-term value.

- Consultation with specialists: Seek expert advice if unsure to avoid selection errors and ensure project success.

Conclusion

The non woven geotextile price is determined by material grade, GSM strength, production technology, and project application. With its excellent mechanical performance, filtration capability, and long lifespan, non woven geotextile is a cost-efficient solution for civil engineering, environmental protection, and large-scale construction projects.

For reliable quality and professional service, we recommend choosing The Best Project Material Co., Ltd.(BPM Geosynthetics).