Geo Membrane Liner

Geo Membrane Liner is a high-quality waterproof lining material that can be relied on to prevent water from leaking, keeping the environment and other things safe from contamination. Its top-quality polyethylene resin source offers the material good durability, high resistance to chemicals, and a long service life. These characteristics make the material a perfect fit for a variety of civil engineering and environmental projects.

- It has excellent impermeability characteristics which makes it highly effective at leak prevention.

- The liner shows high chemical and UV resistance, making it suitable for harsh environments.

- It has a strong resistance against punctures and tears which is ideal for long-term use.

- The material is very flexible and can be easily welded, installed, and maintained.

- It is compatible with applications such as landfills, ponds, canals, mining, wastewater treatment, and aquaculture.

Being a product with stable quality and highly effective performance in terms of the cost, Geo Membrane Liner is a trustworthy choice for projects that require secure containment and waterproof protection that lasts for a long time—available for bulk ordering and quick delivery.

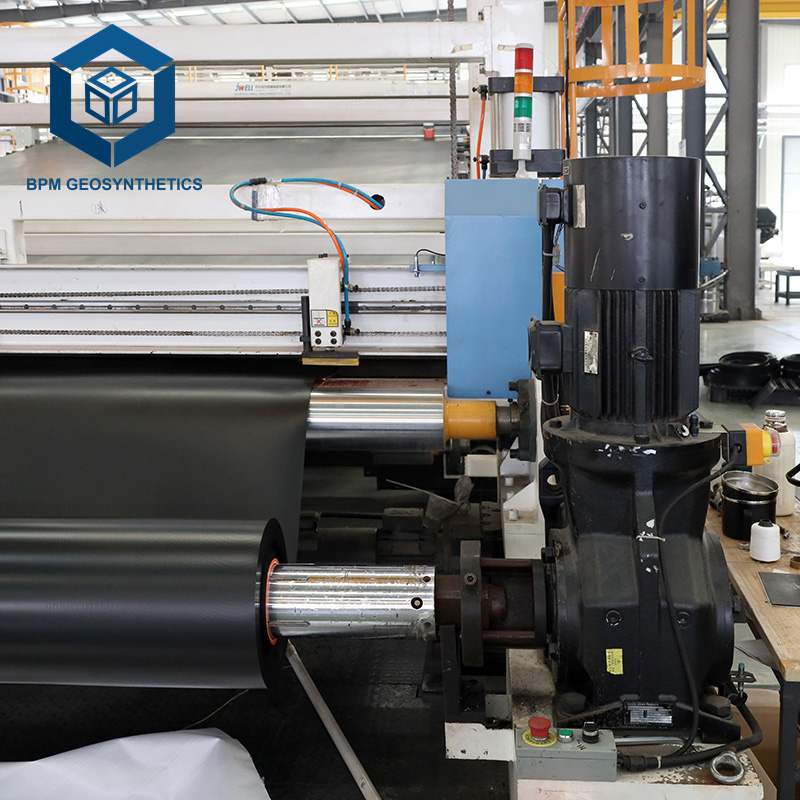

The Geo Membrane Liner is an impermeable, geosynthetic, and top-grade material specially designed for liquid containment, waterproofing, and environmental protection applications in the civil, environmental, and industrial sectors. The geomembrane liner made of a high-quality grade of polyethylene resins and by a combination of advanced extrusion and calendaring technology is able to provide exceptional durability, outstanding chemical resistance, and long-term performance even when operated under very harsh conditions.

1. Geo Membrane Liner Material Composition and Structure

Geo Membrane Liners are composed mainly of HDPE (High-Density Polyethylene), LLDPE (Linear Low-Density Polyethylene), or LDPE (Low-Density Polyethylene), with the choice being guided by the engineering, environmental, and performance criteria. Each of these geo membrane material types has its unique mechanical and chemical advantages, which in turn means they can be used for a wide array of containment and waterproofing projects.

1.1 HDPE Geo Membrane Liner

The geo membranes are known for their high density, great tensile strength, and high chemical resistance. Having a rigid molecular structure, HDPE liners have low elongation and excellent resistance to puncture, stress cracking, and UV radiation. This is why HDPE geomembranes are most often used in landfills, mining containment, hazardous waste facilities, industrial ponds, and wastewater treatment plants, where the need is for very durable and chemically stable materials.

1.2 LLDPE Geo Membrane Liner

The LLDPE geomembranes are produced from linear low-density polyethylene, a material that possesses greater flexibility and elongation than HDPE. Thanks to its greater resistance to deformation and improved stress distribution, an LLDPE liner will be able to conform to uneven subgrades, settlement-prone areas, and complicated geometries just perfectly. Example applications include pond liners, reservoirs, canals, and secondary containment systems, all of which call for liners that can be flexible and conformable.

1.3 LDPE Geo Membrane Liner

LDPE geomembrane deliver the advantages of being soft, highly elastic, and excellently adaptable to irregular surfaces. Even though LDPE liners have less tensile strength when compared to HDPE and LLDPE, they provide a high level of effectiveness at low-load waterproofing applications. Examples are decorative ponds, landscaping projects, and water containment tasks of a light nature. Due to the ease involved in handling and installation, they constitute a cost-effective solution for projects that are small or have low-demanding levels.

1.4 Surface Structure and Texturing Options

Whether smooth or textured surfaces are used for the geomembrane depends on the specific applications involved. Smooth geomembrane liners are largely employed in flat installations as well as locations that demand easy cleaning and welding. Textured geomembrane liners, offered in single-sided as well as double-sided versions, have an embossed or structured finish that helps in increasing the frictional resistance. More interface friction leads to better stability of the slope, thus, the necessity of textured geomembranes for outdoors and landfill lining systems on steep slopes, embankments, etc.

1.5 Manufacturing Process and Structural Integrity

The production of the hdpe membrane sheet uses cutting-edge extrusion, blow molding, or calendering technology, thus guaranteeing uniform thickness, consistent material distribution, and excellent mechanical properties. Impeccable quality control during manufacturing guarantees a homogeneous structure, solid molecular bonding, and a trustworthy performance that complies with international standards such as ASTM, GRI-GM13, and EN specifications.

2. Geo Membrane Liner Key Components and Functionalities

Geo membrane liners are made with the intention to last and perform reliably under the most challenging containment and waterproofing conditions. The mainframe of these high density polyethylene geomembrane is built from highly advanced composites of polymers which give these liners a number of outstanding features such as extremely low water permeability, high tensile strength, resistance of diverse chemical, and weather conditions. Due to this geomembrane liners can be used not only in civil but also in industrial engineering projects.

2.1 Impermeability and Leakage Prevention

Geomembrane sheets are characterized by their very low permeability coefficients which makes them very efficient barriers to the diffusion of liquids and gases. Such an impermeable membrane effectively ensures that no kind of water contamination substances such as the water itself, leachate, chemicals, and other hazardous pollutants can leak out of the system throughout the linings and pollute the surrounding soil and groundwater. Besides the continuous sheet design, the impermeable geomembrane’s features a high-quality sealed welded seams which add to the overall containment capacity thus ensuring total system integrity.

2.2 Chemical Resistance and Environmental Stability

HDPE geomembrane sheets are made to be highly resistant to chemical attack thus they can be used even in the most aggressive environments. Polyethylene geomembrane is able to resist a very broad range of chemicals such as acids, alkalis, salts, hydrocarbons, and different industrial effluent chemicals. Another positive aspect is that they are highly UV resistant as well as antioxidant so they can be used outdoor for a long period without significantly losing the properties. These features allow predictable and constant performance in a variety of facilities such as waste dumps, mines, wastewater treatment plants, chemical storage, etc.

2.3 Mechanical Strength and Load Resistance

The product is made with the functionalities of high tensile strength, elongation, and tear resistance in mind so that it not only accommodates heavy loads, subgrade settlement, and the overall construction stresses but also remains safe and sound during these loadings and impacts. Its top-notch puncture resistance is a defense against damage caused by thin and sharp aggregates, roots as well as installation equipment. Such a mechanical strength of the product guarantees that it is good for use in the presence of dynamic loads and for a long period of time.

2.4 Stress Crack and Fatigue Resistance

The material of bpm geomembrane especially the ones made from HDPE is developed to resist the environmental stress cracking that is typically caused by the changes in temperature over time as well as the mechanical fatigue due to the repeated loading, which are the main reasons for the deterioration of the liners. Thanks to this feature, the need for replacement of the liner is hugely reduced in the case of continuous pressure or movement.

2.5 Thermal Performance and Weather Adaptability

Geomembrane in hdpe keep most of their physical characteristics unchanged when exposed to one or the other extreme of a temperature scale and hence give good results under both hot and cold weather conditions. What is more, hdpe smooth geomembrane can absorb the effects of thermal expansion and contraction without being damaged or distorted so they are ideal for the projects exposed to the seasonal changes of climate.

3. Geo Membrane Liner Environmental and Safety Benefits

The Geo Membrane Liner is constructed following the rigorous environmental and safety standards, offering dependable protection along with the facilitation of sustainable engineering and construction practices.

3.1 Environmental Safety and Non-Toxicity

The Bio-Degradable impervious geomembrane is neither toxic nor has it any odors. Besides, it is chemically inert which makes it an absolutely safe material for potable water storage, aquaculture as well as other environmentally sensitive areas. It does not cause any harm to the environment by releasing any dangerous substances both into soil or water thus is in line with the norms of environmental conservation.

3.2 Long Service Life and Sustainability

The pe geomembrane is a perfect product for Extended service life resulting from the successful inhibition of the deleterious effects of:- aging, ultra violet light (UV), and chemical exposure)- Their embeddment in a smooth geomembrane contributes to a sustainable mode of construction by reducing the need to use more material that leads to less waste and overall lower life cycle cost.

3.3 Soil and Groundwater Protection

Waterproof geomembrane provide an effective and impenetrable barrier that safeguards the soil and ground water against contamination. This is mainly achieved when the liner is used as landfill liner, in industrial contamination system and in waste water treatment plants etc. Its dependable and flawless sealing function is very instrumental in the task of protecting the surrounding nature and human health.

4. Geo Membrane Liner Application Areas

Geosynthetic membrane liners have become a versatile solution utilized in numerous projects across environmental, civil, and industrial engineering disciplines because of their perfect impermeability, longevity, and capability to adjust to different site conditions.

4.1 Environmental and Waste Containment

Geo Membrane hdpe liner have become an integral part of landfill containment systems, landfill covers, hazardous waste disposal, and industrial waste storage facilities. HDPE membrane offer the isolation of contaminants from the environment, thus they stop the migration of leachate and protect the adjacent soil and groundwater.

4.2 Mining and Energy Applications

HDPE geomembrana find their application in mining and energy sectors on heap leach pads, tailings ponds, solution ponds, and biogas digesters. Their high chemical resistance coupled with their mechanical strength guarantees the safe confinement of aggressive solutions and by-products.

4.3 Water Management and Hydraulic Engineering

Geomembrana in hdpe significantly contribute to wastewater and sewage treatment plants, irrigation canals, reservoirs, dams, and water storage ponds. Their super waterproofing performance drastically limits water loss and thus elevates the efficiency of the systems.

4.4 Infrastructure and Construction Waterproofing

Geomembrane liners are very common in the waterproofing of tunnels, protection of basements and foundations, underground structures, and artificial lakes in the domain of civil construction. Their pliability and strong sealing properties make them very effective for intricate structural designs.

5. Geo Membrane Liner Specifications and Customization

Geo Membrane Liners come in a variety of specifications to satisfy different engineering, environmental, and project-specific requirements, thereby, providing the necessary flexibility and adhering to international standards.

5.1 Thickness and Dimensional Options

Geomembrane liner come in a range of thicknesses, such as 0.2 mm to 3.0 mm, with tailored widths and roll lengths to fit different installation conditions and project scales. This range helps to minimize welding work and material wastage on the spot.

5.2 Surface Types and Color Options

These geomembrane sheet is capable of being supplied with smooth, one side textured, or double sides textured surfaces depending on how stable the slope is and the level of friction needed. Numerous colors are on offer to aid visual inspection, temperature regulation, or project recognition.

5.3 Standards Compliance and Quality Control

Manufacturing of hdpe geomembrane liner can be done in line with standards like ASTM, GRI-GM13, GRI-GM17, and EN, thus ensuring the quality is always maintained, the products perform reliably, and they also meet international requirements. Thorough quality checks are rigorously performed throughout manufacture and testing.

5.4 Customization and OEM Services

OEM and project-specific solutions provide for specification modification, branding, and packaging. To cater for the unique design, regulatory, or environmental needs of a project, hdpe geomembrane sheet can be customized, which allows the versatile application of engineering support.

6. Geo Membrane Liner Cost Efficiency and Service Life

Geo Membrane Liner has a great cost-efficiency ratio when the aspects of long-term performance and durability are considered. It was determined that the material with different types, quality of installation, and application conditions can provide a service period of 20–50 years or more, thus it offers a reliable containment and waterproofing function over these long periods.

Its high resistance to aging, chemicals, and environmental stress minimizes maintenance and replacement requirements, significantly reducing lifecycle costs. In addition, the liner’s ease of handling, welding, and installation helps lower labor time and construction expenses, making the Geo Membrane Liner a cost-effective solution while maintaining consistent performance throughout its service life.

Summary

The Geo Membrane Liner is a high-performance geosynthetic solution designed for reliable waterproofing, containment, and environmental protection in demanding engineering applications. With excellent impermeability, chemical resistance, mechanical strength, and long service life, it is widely used in landfills, mining, water management, and infrastructure projects.

The Best Project Material Co., Ltd.(BPM Geosynthetics) Geo Membrane Liner is manufactured using 100% virgin raw materials under strict quality control and complies with international standards such as ASTM and GRI-GM13. Combining stable quality, competitive pricing, and professional technical support, BPM Geosynthetics is a trusted supplier for projects requiring durable, safe, and cost-effective geomembrane solutions.