How to Choose Right Pond Dam Liner?

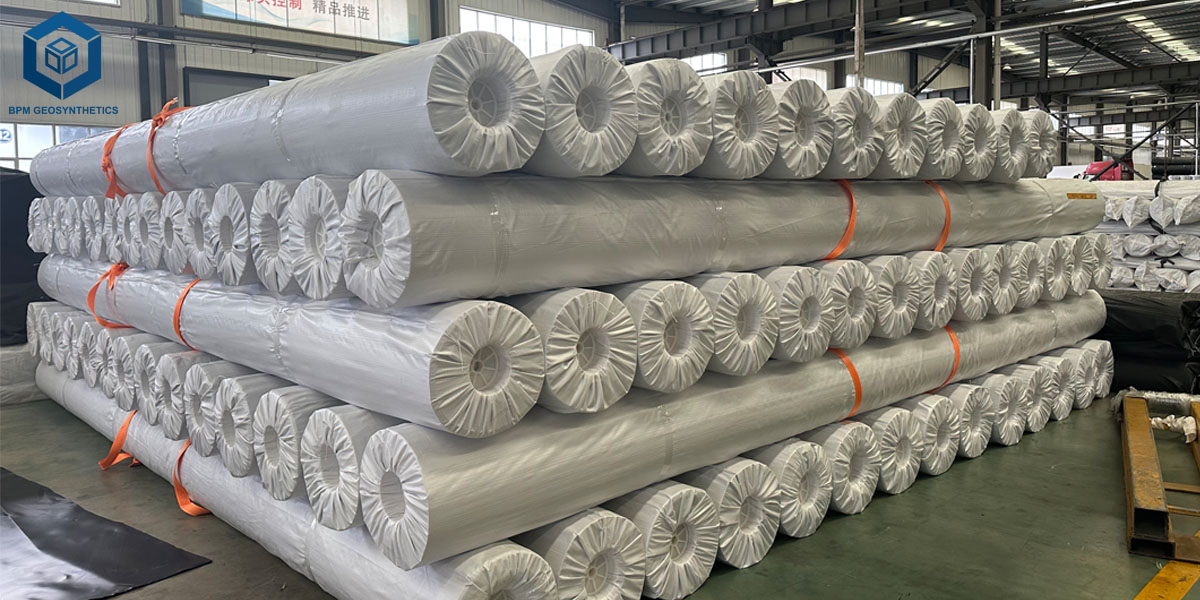

More and more Pond Dam Liner are very popular in recent years, widely utilized in a multitude of applications with its versatility and adaptability. BPM geomembrane have many applications where the Pond Dam Liner serves as a reliable barrier to prevent water seepage and ensure efficient water management.Nowadays, many clients do not know how to choose Right Pond Liner.This article will briefly discuss how to choose Right Pond Dam Liner.

1. Brief Introduction to Pond Dam Liner

1.1 Definition of Pond Dam Liner

Pond Dam Liner also known as geomembrana liner, geomembran liner, or membrane liner,is the low permeable synthetic geo membrane liner and geotechnical engineering materials which is widely used for solid waste containment, mining and water containment applications.

2. Pond Dam Liner Types and its Brief Applications

There are different types of hdpe dam liner available in China, each designed for specific applications. Here are some common types and their brief applications.

2.1 Smooth Pond Dam Liner

BPM plastic dam liners are designed and made of high quality polyethylene resin with proportional carbon black antioxidant, anti-aging and UV-resistance materials which exhibit impermeable and ultraviolet resistance properties. Compared with traditional concrete and compacted clay, smooth geomembrana have proven to be more cost effective, safe and fast deployment. Our HDPE membrane liners are widely used for solid waste landfills, waste containment, aquaculture and water treatment system, etc.

2.1.1 Aquaculture Applications

HDPE pond liner is used in fish ponds, shrimp ponds, and different aquaculture structures to stop seepage and hold smooth water. HDPE liner helps create a steady and wholesome developing surroundings for aquatic species.

2.1.2 Landfill and Leachate Containment

As a landfill liner and cover, it correctly blocks leachate from polluting soil and groundwater. It is additionally used in leachate regulating swimming pools for secure storage and remedy of waste liquids.

2.1.3 Water Treatment and Industrial Pools

HDPE geomembrane liner is utilized in strength plant adjustment ponds and sewage cure structures for impervious water containment. Its sturdy chemical resistance ensures long-term reliability in quite a number industrial processes.

2.1.4 Mining Industry Use

In mining, the hdpe dam liner is used for washing ponds, heap leaching pads, leachate series pools, and tailings seepage control. It affords a durable barrier to stop chemical leakage and shield the environment.

2.1.5 Multi-Industry & Environmental Protection Projects

The pond liner hdpe is extensively used in water conservancy, municipal works, landscaping, petrochemical facilities, agriculture, and more. Its sturdiness and impermeability make it appropriate for various environmental safety needs.

Specifications of Smooth Pond Dam Liner

Mechanical Properties | Thickness | mm | D5199 | 0.2 | 0.3 | 0.5 | 0.75 | 1.00 | 1.25 | 1.50 | 1.8 | 2.0 | 2.5 | 3.0 | Per roll |

Density | g/cc | D1505/D792 | 0.94 | 90,000 kg | |||||||||||

Tensile Properties | D 6693 | ||||||||||||||

.yield strength | kN/m | Type IV | 3 | 5 | 7 | 11 | 15 | 19 | 22 | 27 | 29 | 37 | 44 | 9,000 kg | |

.break strength | kN/m | 5 | 8 | 13 | 20 | 27 | 35 | 40 | 50 | 53 | 67 | 80 | |||

.yield elongation | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | |||

.break elongation | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D 1004 | 25 | 38 | 62 | 93 | 125 | 156 | 187 | 225 | 249 | 311 | 374 | 20,000 kg | |

Puncture Resistance | N | D 4833 | 71 | 96 | 160 | 240 | 320 | 400 | 480 | 576 | 640 | 800 | 960 | 20,000 kg | |

Stress Crack Resistance | hr. | D 5397 | 500 hr. | per GRI GM-10 | |||||||||||

Carbon Black Content | % | D 4218 | 2.0-3.0% | 9,000 kg | |||||||||||

Carbon Black Dispersion | D 5596 | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | 20,000 kg | ||||||||||||

Reference Properties | Oxidative Induction Time | min | D 3895 | 100 min. | 90,000 kg | ||||||||||

(a) Standard OIT | D 5885 | 500 min. | |||||||||||||

(b) High Pressure OIT | |||||||||||||||

Oven Aging at 85°C retained | % | D 5721 | 55% | per each | |||||||||||

(a) Standard OIT - % | D 3895 | 80% | formulation | ||||||||||||

(b) High Pressure OIT - % | D 5885 | ||||||||||||||

UV Resistance | % | 50% | per each | ||||||||||||

High Pressure OIT - % retained | D 5885 | formulation | |||||||||||||

2.2 Textured Pond Dam Liner

Textured hdpe geomembrane pond liner is a type of geomembrane that is specifically designed and manufactured with a rough surface on one or both sides. This texture greatly improves the friction coefficient, making it highly suitable for applications involving steep slopes and vertical engineering designs. The textured surface also facilitates high-quality thermal fusion welding between adjacent sheets, as they have smooth edges.

Textured hdpe liner geomembrane is engineered with excellent superior shear strength and multi-axial performance. It exhibits high shear strength, significant friction angles, excellent elongation properties, and the highest interface surface friction coefficient. These characteristics contribute to enhanced interface strength when in contact with soils, textiles, geosynthetic clay liners, and other critical interfaces.

- Can be textured on one or both sides for your demands.

- Increased frictional coefficient for steep slopes.

- Outstanding ultraviolet and chemical resistance.

- Outstanding UV Environmental stress crack resistance.

- High tensile strength and low elongation.

- Excellent friction coefficient and tensile strength with Geotextile reinforcement performance.

- Excellent water impermeability, corrosion and aging resistance.

- Advanced stabilization.

- Impermeable, antifouling, antiskid function.

- Light weight, easy construction and good overall continuity.

Specifications of Textured Pond Dam Liner

Test Properties | Unit | Standard | Test frequency | GSO10 | GSO15 | GSO20 | GSO25 |

Thickness | mm | D5994 | per roll | 1.00 | 1.50 | 2.00 | 2.50 |

Asperity Height | mm | D7446 | Every 2nd roll (2) | 0.25 | |||

Density | g/cc | D1505/D792 | 90,000kg | 0.94 | |||

Tensile Properties | |||||||

Yield Strength | KN/m | D6693 Type IV | 9,000 kg | 15 | 22 | 29 | 37 |

Break Strength | KN/m | 10 | 16 | 21 | 26 | ||

Yield Elongation | % | 12 | 12 | 12 | 12 | ||

Break Elongation | % | 100 | 100 | 100 | 100 | ||

Tear Resistance | N | D1004 | 20,000kg | 125 | 187 | 249 | 311 |

Puncture Resistance | N | D4883 | 20,000kg | 267 | 400 | 534 | 667 |

Stress Crack Resistance | hr | D5397(App) | per GRI GM-10 | 300 hr | |||

Carbon black content | % | D4218 | 9,000kg | 2.0-3.0% | |||

Carbon black dispersion | D5596 | 20,000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||

Oxidative Induction Time | |||||||

Standard OIT | min | D3895 | 90,000kg | 100 min | |||

High pressure OIT | D5885 | 90,000kg | 400 min | ||||

Oven Aging at 85°C retained after 90 days | % | D5721 | per each formulation | 55% | |||

Standard OIT | D3895 | 80% | |||||

High pressure OIT | D5885 | 80% | |||||

UV Resistance | |||||||

High Pressure OIT – % retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||

Roll Width | m | 7 | 7 | 7 | 7 | ||

Roll Length | m | 210 | 140 | 105 | 70 | ||

Size stability | % | 2% | |||||

3. How to Choose Right Pond Dam Liner?

3.1 Material Quality

Ensure that the hdpe liner irrigation is made from high-quality materials. The hdpe liner sheet should meet industry standards and specifications for Pond Dam Liner .

Look for manufacturers or suppliers with a good reputation for producing reliable and durable products.

3.2 Width and Length

Determine the required width and length of the hdpe geomembrane sheet pond liner roll based on the dimensions of your project site. Ensure that the supplier can provide the geomembrane hdpe liner roll in the required dimensions to minimize waste and installation effort.

The BPM geomembrane factory can produce the width are 4m, 6m, 7m, 8m,10m.

3.3 Certification and Testing

Check if the hdpe irrigation liner has undergone testing and certification by reputable organizations or laboratories. Look for certifications such as ISO 9001:2015, ISO 14001:2015, to ensure that the geomembrane liner hdpe meets quality and performance standards.

3.4 Chemical Resistance

Assess the chemical resistance properties of the hdpe membrane liner. It should be resistant to a wide range of chemicals typically found in the specific application environment. Request chemical compatibility data from the supplier and verify that it meets your project requirements.

BPM company has its own GAILAP laboratory and a complete laboratory testing system

3.5 Installation Support

Inquire about the supplier's installation support services. Some suppliers may offer technical assistance, training, or installation guidelines to ensure proper installation of the hdpe pond dam liner. This can be beneficial, especially if you are not familiar with the installation process.

3.6 Price and Delivery

Compare prices from different suppliers while considering the quality and specifications of the pond liner hdpe geomembrane. Additionally, ensure that the supplier can deliver the geomembrane hdpe pond liner roll within the required timeframe, especially if you have project deadlines.

Summary

Based on this article’s words, you could know How to Right Pond Dam Liner: The quality is basic and the service is the safeguard. So when buying the Right Pond Dam Liner, hope this article can help you well to do the Right Pond Dam Liner for sale.

If you have upcoming projects or need a trusted liner supplier, The Best Project Material Co., Ltd.(BPM Geosynthetics)is ready to provide high-quality products, expert solutions, and competitive prices. Feel free to request a quotation anytime—thank you for reading!