Geocells for Erosion Control

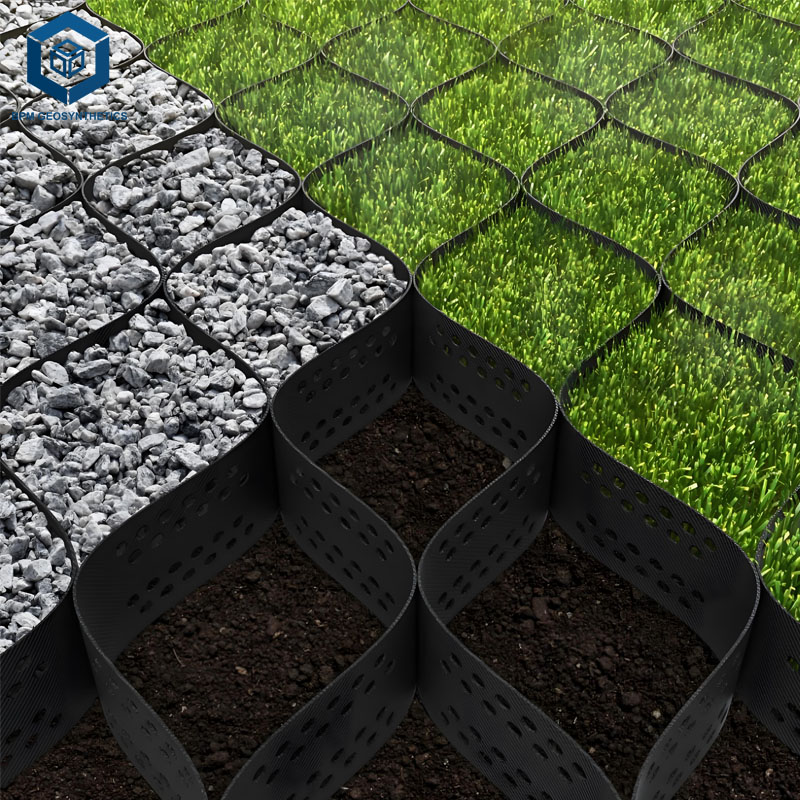

Geocells for erosion control are three-dimensional honeycomb cellular structures that are employed to reinforce weak soils, stop erosion, and increase the stability of slopes. Geocells made of high-strength HDPE enclose soil, aggregate, or sand in each cell thus building a stable and long-lasting system of erosion control suitable for environmental, road, and civil engineering projects.

- High Strength HDPE Material - Resistant to UV, chemicals, and long-term outdoor exposure.

- 3D Soil Confinement - Keeps soil stable and surface erosion issues at bay even on steep slopes.

- Light and Simple Installation - The job site usually requires little or no preparation and thus labor and construction time are significantly cut down.

- Great Load Distribution - Raises the bearing capacity of roadbeds, slopes, and embankments.

- Versatile & Adaptable - Can be used with different types of infill materials such as soil, gravel, and sand.

1. Geocells for Erosion Control Product Overview

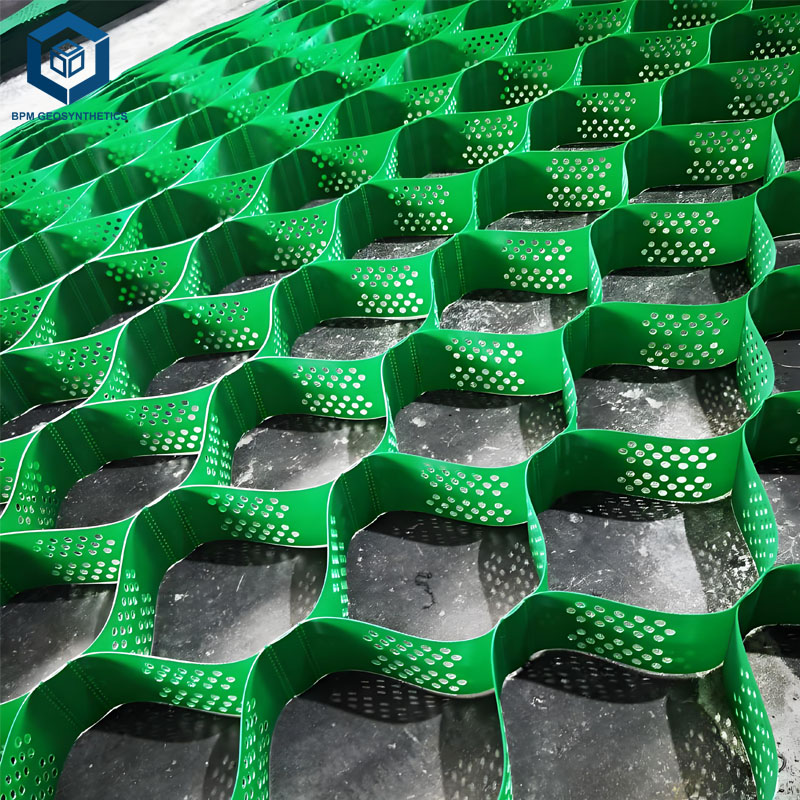

Geocells represent a kind of 3D honeycomb cellular structure units that are obtained by welding or bonding high-strength polymer strips together forming expandable cells. On expansion and infill with soil, gravel, or any other suitable materials, geocell for slope protection deliver a semi-rigid mattress that encloses the infill, distributes the load, and minimizes soil displacement and surface erosion to a great extent. They find a wide use in slope protection, channel lining, road base reinforcement, retention structures, and environmental containment.

2. Geocells for Erosion Control Core Materials & Variants

2.1 Geocells for Erosion Control Core Materials

2.1.1 HDPE (High-Density Polyethylene)

The best and most popular is the material with excellent UV and chemical resistance, high tensile strength, and long-term durability.

2.1.2 PP (Polypropylene)

In certain biaxial/uniaxial configurations, PP geocell can give high stiffness and strength and is a source for that where more rigidity is needed.

2.1.3 Advanced Polymer Blends

Some products have the components (UV stabilizers, antioxidants, carbon black) in them impowering the life span of the device when used in tough environments.

2.2 Geocells for Erosion Control Variants

- Open-Cell Designs: Open-cell (permeable) permits drainage through the spaces between the walls;

- Closed-Cell Designs: Closed-cell (impermeable) are used in places where seepage control is necessary.

2.3 Common Geocell Sizes & Depths

- Cell height: 50 mm to 300 mm (2"–12") is normal; there are deeper cells for heavy-load or deep-root applications.

- Cell diameter (when expanded): 100 mm to 300 mm.

- Roll widths: 1 m to 4 m; lengths are determined by packaging and transport.

3. Geocells for Erosion Control Key Technical Benefits

3.1 Erosion Mitigation

The method of confining the infill forbids surface washout; thus, soil loss is reduced even on steep slopes during heavy rainfalls.

3.2 Slope Stabilization

The increase in shear resistance and passive confinement extend the stability of the slope and lower the sliding risk.

3.3 Load Distribution

The plastic geocell mattress spreads the loads that have been applied laterally over the area, thus the rutting and differential settlement on unbound layers are reduced.

3.4 Material Savings

Enables the use of locally available infill (e.g., sand, gravel, recycled materials), thus the need for imported structural fill is lowered.

3.5 Rapid, Low-Impact Installation

The job of expanding lightweight rolls is done at the location and they are fixed with anchors — very little heavy machinery is used and the construction time is shortened.

3.6 Long-Term Durability

When a polymer is used for the construction, best geocell resists degradation by living organisms, corrosion, and many chemicals.

4. Geocells for Erosion Control Typical Applications

4.1 Slope Protection & Revetments

Within their honeycomb framework, geocell slope erosion control hold the earth, thus, they do not allow the soil to slide out or be carried away by water from steep or unstable slopes. They can be found practically everywhere in nature, on the seaside slopes, along rivers, on the so-called "cut" slopes of highways, and embankments where the requirement for stability of the surface is of long duration.

4.2 Channel & Culvert Lining

The use of perforated geocell in the interiors of drainage channels, stormwater ditches, or culverts gives rise to a highly erosion-resistant lining. The confinement device decreases soil loss during times of flooding and thus, facilitates the use of soil, aggregate, or vegetation as channel lining material, which is of greater durability.

4.3 Road & Rail Subgrade Stabilization

By the use of slope protection geocell, weak subgrades can carry more loads as the latter are spread over a larger area. Consequently, this strengthening leads to less rutting, higher structural safety, and lesser thickness of aggregate layers thus, saving materials and costs in the construction of roads and railways.

4.4 Retaining Wall Backfill

The use of geocell erosion control in the backfill of retaining walls and MSE structures increases the stability of the backfill soils. They decrease the lateral pressure of earth against the wall, stop the ground from sinking, and improve the overall level of resistance to deformation.

4.5 Landfill Capping & Environmental Projects

The application of geocells on landfills serves the purpose of holding down the soil layers against the forces of wind and water erosion. They facilitate the growth of green cover, shield the underlying layers from wear and tear caused by mechanical operations, and help in stabilizing steep slopes of landfills.

4.6 Green Infrastructure

Geocell material play a major role in environmentally friendly projects such as planted slopes, biologically active swales, and stormwater collection systems. They create a stable environment for rapid vegetation growth while at the same time, they provide immediate erosion protection and long-term soil confinement.

5. Geocells for Erosion Control Design Considerations & Engineering Parameters

5.1 Cell Depth & Width

The depth and width of the geo geocell should correspond to the hydraulic shear stress and the load-bearing capability that is anticipated. The deeper the cells the more they can provide confinement and load distribution.

5.2 Slope Gradient

If the slope is steeper than 1:1 (45°), then one should opt for a material of greater strength and anchor the points more closely; also, consider terracing with several small benches.

5.3 Hydraulic Conditions

If the flow is of high velocity then, on top of the geocell slope protection, place a facing of riprap or use larger aggregate infill together with toe protection.

5.4 Vegetation vs. Rigid Protection

The vegetated geocell hdpe need appropriate soil and an irrigation plan; also, a combination of geocell and riprap can be employed in the areas which are changing from one to another.

5.5 Durability & UV Exposure

Put an emphasis on the use of UV-stabilized polymers and plan for the expected service life (for instance, 25–50 years) which is derived from the exposure and project importance.

6. Geocells for Erosion Control Infill Options & Selection Guidance

6.1 Soil (Topsoil/Subsoil)

If vegetated slopes are the goal; then choose erosion-resistant mixtures and think of hydroseeding as well.

6.2 Sand

This is mostly found in applications that take place along the coast or in deserts; also, use geotextile separation layers if that is necessary.

6.3 Aggregates/Gravel

Are used for heavy-duty channels, access roads, and load-bearing surfaces.

6.4 Recycled Materials (Crushed Concrete, Blast Furnace Slag)

Are a sustainable choice — but always check the local standards for their suitability.

6.5 Design tip

Select infill gradation and compaction levels according to hydraulic shear stress (for channels) or bearing requirements (for roads). The combination of vegetation and geocells is most probably the best long-term solution from both the aesthetic and the ecological point of view.

7. Geocells for Erosion Control Performance Metrics & Testing Standards

7.1 Tensile Strength & Elongation

Testing is carried out following ASTM or ISO standards for polymer geosynthetics.

7.2 Joint/Seam Strength

It is essential for the hdpe geocell board connections—tested under peel and shear.

7.3 Creep & Long-Term Deformation

Accelerated aging in the laboratory to predict long-term performance under a continuous load.

7.4 Permeability (for open-cell)

Measured to ensure good drainage and prevent pore pressure buildup.

7.5 Standard References

ASTM series, ISO 10318 (geosynthetics), and local geotechnical design codes.

8. Geocells for Erosion Control Case Studies & Typical Performance Outcomes

8.1 Highway Slope Stabilization

Slope erosion during storms was reduced by more than 80%; the aggregate import costs were cut by 30–50%.

8.2 Riverbank Protection

It provided immediate protection against scour with the following vegetation becoming established within 12–18 months.

8.3 Road Base Reinforcement

Allowed axle loads were increased, and the aggregate layer thickness was reduced by 20–40% depending on subgrade CBR.

9. Geocells for Erosion Control Maintenance & Inspection

9.1 Initial 12 Months

After each major storm, inspections should be frequent. Look for local washouts, vegetative establishment, and anchor integrity.

9.2 Long-Term

Inspection every year, especially at transitions, inlets, and toes, will be sufficient. Minor anchor or seam issues should be repaired without delay.

9.3 Vegetated Systems

Control the spread of invasive plants, keep watering during dry periods, and fix erosion rills early.

10. Geocells for Erosion Control Ordering, Customization & Logistics

10.1 Standard Supply Options

Widths of rolls (1.0 m, 2.0 m, 4.0 m) and depths (50–300 mm) are regular. Bundles of rolls are good for the transport of the material.

10.2 Custom Orders

The depth of the cell, the kind of polymer, the amount of UV stabilizer, and the type of connector can be customized for a large project.

10.3 Packaging & Shipping

It is possible to palletize, shrink-wrap, or put in protective film the rolls of a package for overseas shipment.

10.4 Lead Times

Depend on the volume and the level of customization of the order — approximate lead time for commonly stocked models: 1–4 weeks.

11. Geocells for Erosion Control FAQs

Q1: Could geocells work on very steep slopes?

A: Sure—if it is properly designed using the right strength of materials, anchoring, and possibly terracing or transitional riprap.

Q2: Are geocells good for the environment?

A: They make it possible to use local and recycled infill materials and also support the growth of vegetation, thus less mined aggregates are needed.

Q3: What is the lifespan of geocells?

A: The period of use is generally from 25 to 50 or more years depending on the exposure if the installation is correctly UV-stabilized and done.

Conclusion

Geocells for Erosion Control are an effective means of soil confinement and provide the necessary structural reinforcement that stabilizes slopes, channels, roads, and environmental projects. Their 3D honeycomb design mechanically interlocks soil or aggregate thus, the erosion of the soil is prevented, the load is more evenly distributed, and the growth of vegetation is supported making the whole process sustainable. Besides slope protection, channel lining, road subgrade stabilization, retaining wall backfill, and green infrastructure are among the areas where geocells can be used as a long-lasting and economical solution for rough terrains. You can count on quality and performance if you choose The Best Project Material Co., Ltd.(BPM Geosynthetics) for your geocells.