Geo Composite Membrane

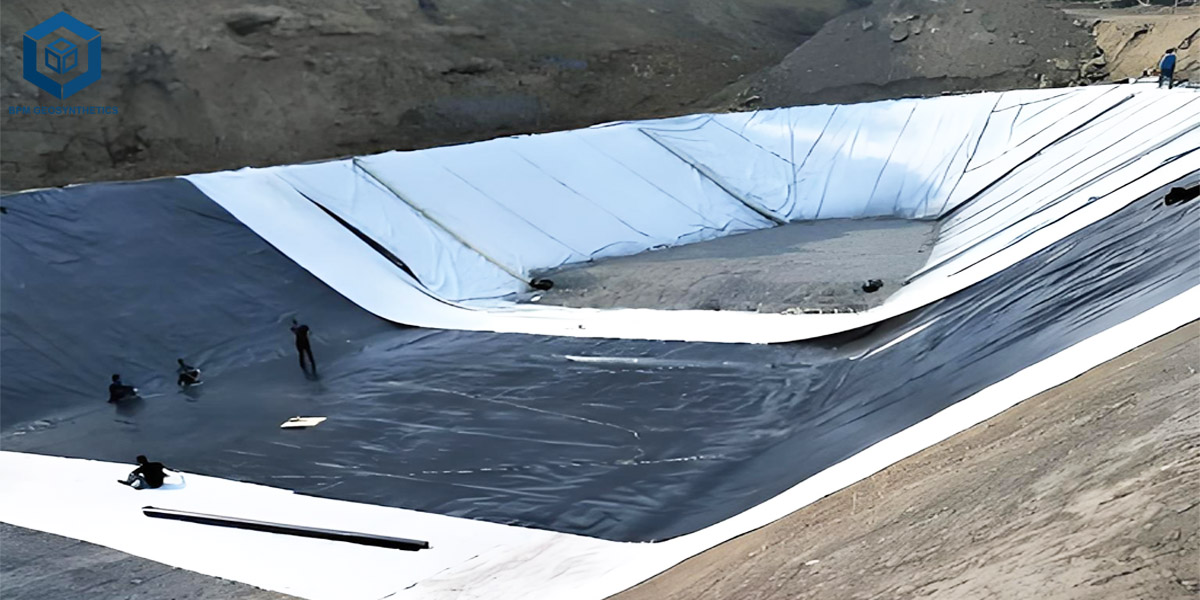

Geo Composite Membrane is a splendid geosynthetic answer combining a geomembrane layer with geotextile layers. It affords most effective waterproofing, soil reinforcement, and environmental safety for a range of engineering projects. Ideal for landfills, reservoirs, ponds, mining, and industrial containment, it ensures long-term steadiness and dependable performance.

- High Tensile Strength: Resists stretching and deformation below heavy loads.

- Durable and Puncture-Resistant: Withstands mechanical injury at some point of set up and use.

- Excellent Waterproofing: Prevents leakage and protects soil and water resources.

- Versatile Applications: Suitable for landfills, mining, reservoirs, ponds, and industrial projects.

Geo Composite Membrane is a high-performance geosynthetic material engineered by way of combining a geomembrane layer with one or greater geotextile layers. This multi-layer shape presents incredible waterproofing, robust soil reinforcement, and dependable environmental protection, making it a versatile answer for a broad vary of civil engineering, industrial, and environmental projects.

Designed to stand up to heavy hundreds and withstand punctures, Geo Composite Membranes make certain long-term steadiness and sturdiness even beneath harsh conditions. They are broadly used in landfills and waste containment structures to forestall leakage, in reservoirs and ponds for water retention, in mining initiatives to stabilize tailings and stop contamination, and in industrial services for chemical or hazardous cloth protection. Additionally, their flexibility and ease of set up make them appropriate for complicated terrains, such as slopes, embankments, and bolstered infrastructure projects.

With these mixed benefits, Geo Composite Membranes furnish a reliable, cost-effective, and environmentally pleasant answer for initiatives that demand each structural reinforcement and impermeability.

1. Types of Geo Composite Membrane

1.1 HDPE Geo Composite Membrane

HDPE composite geomembrane is made from a High-Density Polyethylene (HDPE) geomembrane laminated with geotextile fabric layers. This mixture presents excessive chemical resistance, exceptional waterproofing, and UV stability, making it notably long lasting in harsh environmental conditions. It is often used in landfills, mining containment areas, and industrial initiatives the place long-term leakage prevention and soil reinforcement are critical.

- Prevents leakage of hazardous materials

- Maintains structural integrity beneath heavy loads

- Resistant to chemical corrosion and weathering

1.2 LDPE Geo Composite Membrane

LDPE composite geomembrane liner makes use of Low-Density Polyethylene (LDPE) as the LDPE geomembrane layer mixed with geotextiles. It is recognised for its flexibility and ease of installation, permitting it to adapt to uneven or complicated terrain. This kind is broadly utilized in reservoirs, ponds, irrigation channels, and landscaping projects.

- Easy to set up on irregular surfaces

- Provides dependable waterproofing and soil containment

- Lightweight and within your budget for average load projects

1.3 Bentonite Geo Composite Membrane (GCL)

Bentonite Geo Composite Membrane, additionally known as Geosynthetic Clay Liner (GCL), combines a bentonite clay layer with geotextile fabric or a geomembrane liner. The bentonite layer swells on contact with water, forming a self-sealing water resistant barrier, making it perfect for stopping leakage in touchy applications. GCL liner is often used in landfill liners, reservoirs, ponds, and environmental safety projects.

- Forms a herbal impermeable barrier

- Reduces the hazard of leakage even with minor punctures

- Environmentally pleasant and sustainable

1.4 Textured or Roughened Geo Composite Membrane

This kind aspects a textured or roughened geomembrane surface, blended with geotextiles to enhance bonding with soil or concrete. The textured geomembrane enhances slip resistance and reinforcement performance, making it appropriate for slopes, embankments, conserving walls, and bolstered containment systems.

- Improves balance on inclined surfaces

- Reduces threat of soil sliding or displacement

- Maintains waterproofing whilst improving reinforcement

1.5 Multi-Layer Geo Composite Membrane

Multi-Layer Geo Composite Membrane combines a couple of geomembrane and geotextile layers for more durability, strength, and heavy-duty performance. It is designed for large-scale landfills, mining tailings, industrial containment, and different vital infrastructure initiatives the place most reliability is required.

- Withstands heavy mechanical stress and intense conditions

- Long-term overall performance with minimal maintenance

- Provides each waterproofing and structural reinforcement

2. Material Composition and Structure of Geo Composite Membrane

A Geo Composite Membrane is an engineered geosynthetic fabric that combines a geomembrane layer with one or greater geotextile layers, growing a multi-functional gadget for waterproofing, soil reinforcement, and environmental protection.

2.1 Geomembrane Layer:

Typically manufactured from HDPE (High-Density Polyethylene), LDPE (Low-Density Polyethylene), LLDPE (Linear Low-Density Polyethylene), or PVC.

Thickness commonly levels from 0.2 mm to three mm, customizable relying on challenge requirements.

Acts as the main impermeable barrier, presenting exquisite resistance to water, chemicals, UV radiation, and environmental aging.

Available with smooth or textured surfaces, the place textured surfaces enhance adhesion to soil, concrete, or bentonite layers for more desirable stability.

2.2 Geotextile Layer:

Made from woven or non-woven polyester (PET) or polypropylene (PP) fibers.

Weight or thickness levels from 200 g/m² to a 1000 g/m², adjustable primarily based on the stage of reinforcement and filtration required.

Functions as a protecting cushion for the HDPE geomembrane liner, distributes mechanical masses evenly, enhances puncture and tear resistance, and lets in managed filtration for drainage applications.

Multi-layer geotextiles can be laminated with the impermeable geomembrane for more sturdiness and strength, appropriate for heavy-duty engineering projects.

2.3 Lamination and Fabrication Process:

Geomembrane and geotextile layers are bonded the usage of thermal lamination, extrusion lamination, needle punching, or adhesive bonding, making sure uniform thickness and dependable layer adhesion.

Optional enhancements consist of floor texturing, reinforcement grids, or bentonite infill layers to meet unique engineering or environmental requirements.

The manufacturing follows strict satisfactory manipulate requirements to warranty long-term overall performance below heavy loads, publicity to chemicals, and harsh environmental conditions.

This layered shape allows Geo Composite Membranes to grant long lasting waterproofing, structural reinforcement, and dependable environmental safety throughout a huge vary of applications, together with landfills, reservoirs, ponds, mining tailings storage, industrial containment, and civil engineering projects.

3. Key Features of Geo Composite Membrane

Geo Composite Membrane is engineered to supply most useful mechanical strength, durability, and environmental protection, making it appropriate for a huge vary of geotechnical and water containment applications. Its predominant points include:

3.1 Geo Composite Membrane High Tensile Strength

The composite pond liner is designed to stand up to heavy hundreds and structural stresses barring tearing or deforming. This property ensures steadiness in functions such as landfills, mining sites, and reservoir tasks the place excessive stress and agreement may additionally occur.

3.2 Durability and Puncture Resistance

With a difficult composite structure, the landfill composite liner resists punctures, tears, and abrasion throughout transportation, installation, and long-term use. This enhances safety, reduces the hazard of damage, and extends provider life.

3.3 Geo Composite Membrane Excellent Waterproofing

The mixture of high density polyethylene geomembrane and non woven geotextile fabric layers presents a robust barrier towards water seepage, leakage, and soil contamination. This function is vital for defending groundwater, stopping erosion, and making sure environmental safety.

3.4 Chemical and UV Resistance

Composite geomembrane liner keeps secure overall performance when uncovered to harsh environments such as chemicals, acids, salts, or extended UV radiation. This resistance makes it fairly dependable for outside and industrial projects.

3.5 Geo Composite Membrane Flexible and Lightweight

Despite its strength, the membrane geo fabric stays handy to cut, shape, transport, and install. Its flexibility permits it to adapt to uneven or irregular terrain whilst retaining sealing performance, making it sensible for complicated engineering conditions.

4. Applications of Geo Composite Membrane

4.1 Geo Composite Membrane for Landfill Liners

Non woven geotextile membrane is extensively used in contemporary landfill development to furnish tightly closed containment of waste. It prevents leachate leakage into the surrounding soil and groundwater, defending the surroundings from hazardous pollution and making sure compliance with strict environmental regulations.

4.2 Geo Composite Membrane for Reservoirs and Ponds

In water storage projects, the geotextile fabric membrane ensures long-term water retention by way of offering an impermeable barrier. It minimizes seepage losses, continues constant water levels, and helps enhance the effectivity of reservoirs, fish ponds, and irrigation systems.

4.3 Geo Composite Membrane for Mining Projects

The membrane performs a key function in mining operations, in particular in tailings storage amenities and heap leach pads. It reinforces soil stability, prevents seepage of contaminated water, and protects surrounding ecosystems from detrimental resources generated throughout mining activities.

4.4 Geo Composite Membrane for Industrial Containment

For industries dealing with chemicals, oils, or hazardous liquids, Geocomposite membrane gives dependable containment. It is normally used in chemical plants, storage tanks, and hazardous waste amenities to stop leaks, spills, and soil or water contamination.

4.5 Geo Composite Membrane for Infrastructure Projects

In civil engineering works such as roads, highways, and embankments, the composite geomembrane improves soil reinforcement and drainage control. It prevents erosion, will increase load-bearing capacity, and enhances the long-term steadiness of transportation and infrastructure projects.

Summarize

Geo Composite Membrane combines excessive strength, durability, and outstanding waterproofing performance, making it a dependable answer for landfill liners, reservoirs, mining, and industrial containment projects. With most beneficial chemical resistance, UV stability, and ease of installation, it offers long-term safety in traumatic environments.

For super Geo Composite Membranes, we suggest deciding on The Best Project Material Co., Ltd.(BPM Geosynthetics), a depended on producer with validated know-how in geosynthetic solutions.