HDPE Plastic Liner

HDPE plastic liner is a durable, universal, and environmentally pleasant answer extensively used in a variety of applications, together with landfill lining, ponds, and agricultural projects. These liners are made of wonderful polyethylene, which has terrific chemical resistance, UV radiation resistance, and bodily stress resistance, making them an perfect preference for business and residential use.

-Durability: resistant to punctures, tears, and intense climate conditions, making sure long-lasting performance.

-Chemical resistance : It can withstand quite a number chemicals, making it appropriate for industrial applications.

-UV balance : Designed to stand up to UV radiation besides degradation, making sure durability in outside environments.

-Environmental safety : helps stop soil and water air pollution and promotes sustainable development.

HDPE plastic liner is an superior high-performance liner designed for more than a few applications, which includes environmental protection, water useful resource management, and agricultural use. These liners are made of outstanding polyethylene and are regarded for their brilliant sturdiness and elasticity. They have gorgeous resistance to punctures, tears, and environmental pressures, making them an perfect preference for landfills, ponds, reservoirs, and farmland.

One of the essential benefits of HDPE plastic liner is its chemical resistance, which approves it to face up to publicity to more than a few supplies except degradation. This makes them specially appropriate for industrial functions the place hazardous components may also be present. In addition, the HDPE plastic liner has passed through UV stabilization treatment, making sure its integrity and overall performance even after extended publicity to sunlight.

In phrases of the environment, HDPE plastic liner performs a imperative function in stopping soil and water pollution, thereby defending ecosystems and advertising sustainable practices. Its light-weight and bendy traits make set up easy, lowering labor expenses and mission time. Overall, HDPE plastic liner gives a dependable and reasonably-priced answer that meets the wants of present day development and environmental management.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | D1505/D792 | 90.000kg | 0.94g/cc | ||||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 5 3 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

HDPE Plastic Liner Features

-High Durability : The HDPE plastic liner is puncture and tear resistant, making sure long-lasting overall performance in harsh environments.

-Chemical resistance: They can face up to quite a number chemicals, making them appropriate for industrial functions and hazardous waste control.

-UV steadiness : The HDPE plastic liner is designed to face up to UV radiation and hold its structural integrity and overall performance even in outside environments.

-Environmental Protection: These liners efficiently stop soil and water pollution, guide environmental practices, and comply with environmental regulations.

-Flexibility : HDPE's light-weight and flexibility make it effortless to manage and install, adapting to initiatives of quite a number shapes and sizes.

-Cost effectiveness: HDPE plastic liner has sturdiness and low renovation requirements, imparting an in your price range and environment friendly answer for the duration of its provider life.

-Temperature resistance: They keep overall performance over a broad temperature range, making them appropriate for quite a number climatic conditions.

-Easy to set up : HDPE plastic liner can be rapidly deployed, decreasing labor time and prices related with installation.

-Recyclability : The HDPE plastic liner is made of recyclable materials, which make contributions to sustainable improvement and can be reused at the cease of its lifecycle.

Applications of HDPE Plastic Liner

-Landfill Site : HDPE plastic liner is broadly used in landfills to forestall leachate from contaminating groundwater, making sure environmental safety and compliance with regulations.

-Pond lining: They are an perfect preference for pond and reservoir lining, supporting to save water and stop leakage, whilst additionally stopping pollution.

-Agricultural use : HDPE plastic liner is used for agricultural purposes such as irrigation structures and fertilizer containment to beautify soil and water conservation and soil protection.

-Mining: HDPE plastic liner is used for tailings administration and waste manipulate in mining operations, imparting a dependable barrier to forestall environmental pollution.

-Wastewater treatment: These HDPE plastic liners are critical in wastewater cure facilities, supporting to manage sludge and forestall leakage into surrounding soil and water sources.

-Aquaculture : HDPE plastic liner creates a managed surroundings in fish farming and aquaculture systems, assisting wholesome aquatic organisms whilst stopping water loss.

-Construction initiatives : HDPE plastic liner is regularly used in a range of constructing applications, which includes conserving partitions and drainage systems, to control water waft and stop erosion.

-Dangerous Goods Control : Used for wiring areas the place hazardous items are saved or disposed of, offering protection obstacles to forestall leakage and spillage.

-Entertainment amenities : HDPE plastic liner can be discovered in leisure water aspects such as swimming swimming pools and synthetic lakes to make certain water retention and safety.

Company Profile

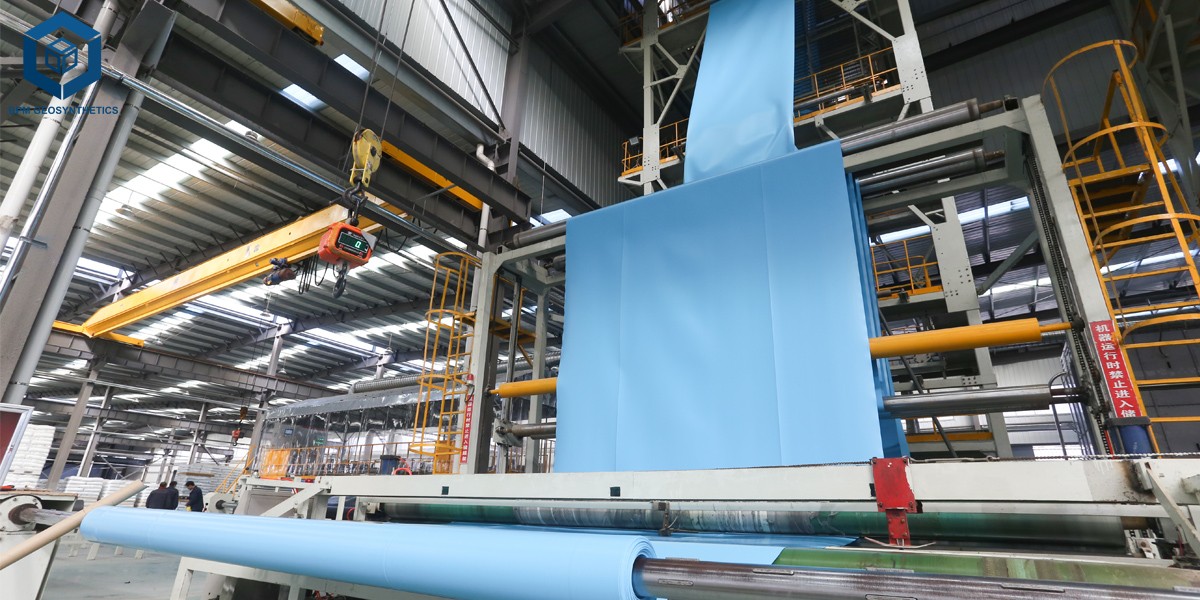

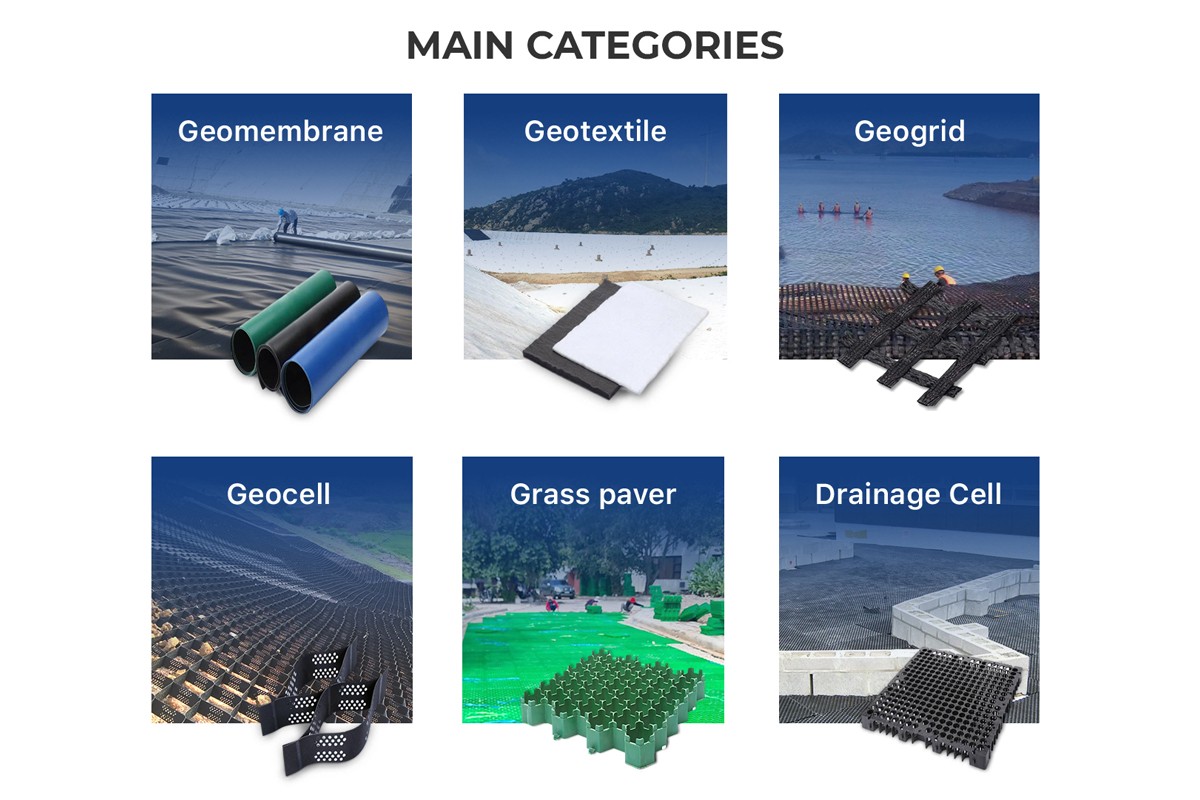

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a leading manufacturer and exporter of high-quality geosynthetic products, including geomembranes, geotextiles, geogrids, geocells, and geosynthetic clay liners (GCL). Our products, certified by EU CE and GLP, have passed ISO 9001, ISO 14001, and OHSAS 18001 standards, and are recognized for their quality, performance, and durability.

BPM GEOSYNTHETICS has been committed to providing one-stop services for global customers in the research and development, production, sales, and export of geosynthetic materials since its establishment in 2007. The company has 120 senior technical talents specializing in geotechnical materials. The manufacturing factory covers an area of over 36000 square meters and is equipped with industry-leading automated production equipment and professional testing instruments. Product innovation, quality assurance, and customer satisfaction have always been BPM commitment to partners.

We're committed to innovation and quality, offering flexible cooperation and the best solutions for engineering projects worldwide. Our products are utilized in various sectors like aquaculture, erosion control, drainage systems, municipal engineering, mining, and landscaping. We look forward to partnering with you to solve complex challenges with our high-performance geosynthetic products.