Harga Geomembrane HDPE 2 mm

Geomembrane HDPE 2 mm is a high-strength waterproof liner used for industrial, pond, landfill, reservoir, and other civil engineering applications projects. 2 mm thickness offers very good mechanical resistance, long service life, as well as the best anti-leak performance for extreme conditions. Informasi harga geomembrane HDPE 2 mm biasanya tergantung pada spesifikasi, kuantitas, ukuran roll, dan biaya pengiriman.

1. High Mechanical Resistance

Geomembrane HDPE 2 mm features very high tensile strength and puncture resistance, thus it is ideal for heavy-duty applications such as mines and landfills.

2. Chemically & UV Resistant

It is stable against chemicals, corrosion, and sunlight exposure, thus having a longer service life.

3. Price Influenced by Several Factors

Price depends on the specification, roll size, quantity of the order, HDPE (virgin/recycle) material, and shipping cost.

1. What is HDPE Geomembrane 2 mm?

HDPE Geomembrane 2 mm is a thick and dense high-density polyethylene waterproof membrane which is basically a lining material used for large-scale civil engineering, mining, landfill, and water containment projects.

The 2 mm layer offers supreme wear resistance for the long run, an absolute resistivity to mechanical damages, and almost total chemical protection, thereby it is the first choice of usage in places where the mechanical load is high or the chemicals are aggressive.

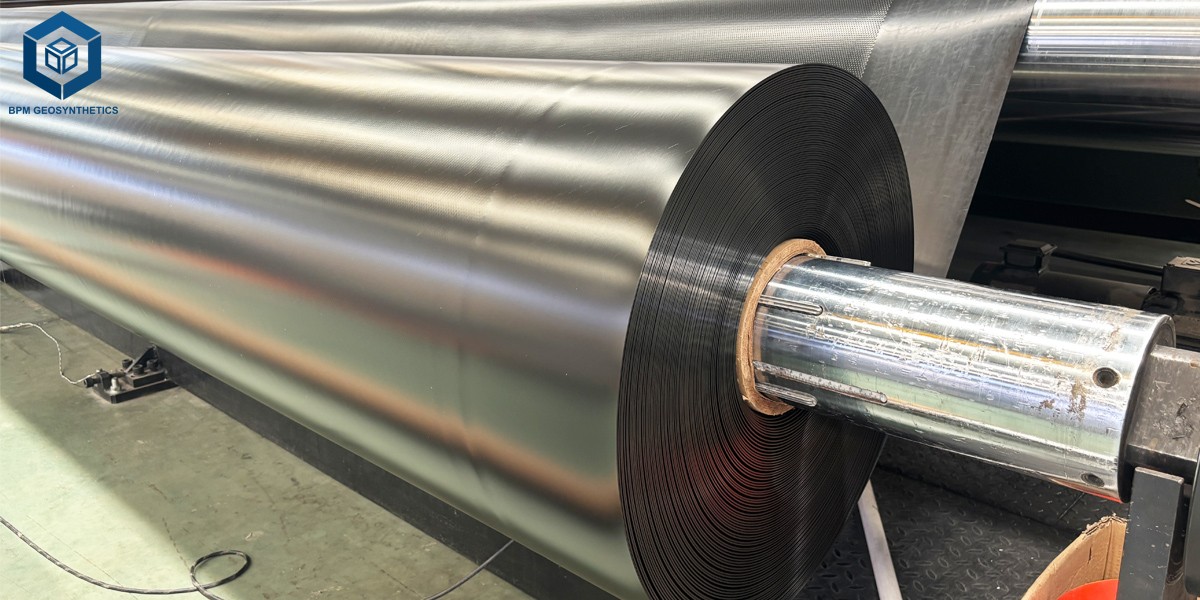

These 2mm hdpe liner is usually manufactured by the blown film or extrusion method, which ensures that the thickness is even, the surface is of high quality as well as the sealing is excellent.

2. The Harga Geomembrane HDPE 2 mm is Influenced by Multiple Factors

The price of a 2 mm HDPE geomembrane is a reflection of the several technical, production, and market-related are factors which directly influence its operations, life span and, in general, how well it fits into the project.

2.1 The Price Depends on the Quality of Raw Materials

The type and the grade of the HDPE resin that is used for manufacturing the product have the most to do with the final cost.

2.1.1 100% Virgin HDPE Resin

This one-of-a-kind raw material gives amazing durability, higher tensile strength, and long-term resistance to aging. It is usually specified for critical engineering projects such as landfills, mining pads, and water reservoirs, which is why the product cost is a bit higher but at the same time reasonable.

2.1.2 Recycled or Mixed Resin

In general, products with recycled content are less expensive but have lower mechanical properties and shorter service life. The materials can only be used in temporary or low-risk areas, while they are strictly prohibited in environmental containment.

2.2 The Price Varies Based on the Manufacturing Method

Different manufacturing process and surface treatment have both an effect on the product's performance and its price.

2.2.1 Double-Sided Smooth Geomembrane

Being the simplest and usually the most affordable version, this product has been designed for uses that require high impermeability and the welding of clean surfaces.

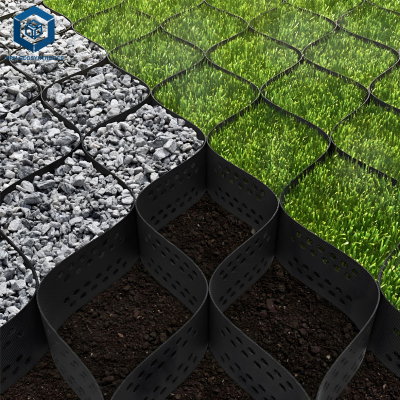

2.2.2 Single or Double Textured Geomembrane

The greatest benefit of texturizing is that it increases the friction on slopes, thus making the one with the steepest or heaviest areas stable. It goes without saying that the additional processing stages and the specialized equipment make the price of the textured geomembrane higher than the smooth one.

2.2.3 Enhanced UV-Resistant Geomembrane

Products having higher carbon black content and/or a special UV stabilizer are more durable when exposed to the outdoors, especially in hot and sunny areas. This is the reason why such a material costs more than its counterparts.

2.3 The Price Is Affected by Roll Size and Custom Specifications

The width of the rolls and the production of custom requirements have an effect not only on the material consumption but also on the manufacturing efficiency.

2.3.1 Standard Roll Width (6–8 meters)

By using a standard size, the whole production process can be efficient, and the output rate can be higher, which is the reason for the competitive pricing maintained.

2.3.2 Custom Width or Extra-Long Rolls

Custom specification means that production needs to be adjusted, extra quality checks performed and sometimes that the speed of the line is slower. Because of these added complexities, the final price per square meter is generally higher.

2.4 The Price Changes Based on Order Quantity

The quantity of the order has a very important role in figuring out the unit cost.

2.4.1 Bulk Orders Reduce the Unit Price

By purchasing in large volumes, factories can plan the raw material procurement more effectively, keep the production schedules stable and reduce the per-unit overhead, thus leading to lower prices.

2.4.2 Small or Sample Orders Have Higher Unit Costs

With low-quantity orders, the same amount of time and labor for setting up is involved but only a limited output is generated, thus leading to a slightly higher cost per square meter.

2.5 The Price Is Influenced by Logistics and Delivery Conditions

The cost that transportation and shipping factors add to the final price that the customer pays is a part of the pricing strategy

2.5.1 Heavier Roll Weight for 2 mm Thickness

Globally, the weight of the freight increases with the thickness of the material and the freight charges will be higher. More shipment handling labor or equipment will be necessary, in some cases, as a natural consequence of the heavier rolls.

2.5.2 Longer Transport Distance

The cost of transport is dependent on how far the place of delivery is. Especially for international shipments or for inland destinations that are far from the main ports, the transportation costs will be higher.

2.5.3 Container Loading Efficiency

If loading is done efficiently, the shipping cost per ton will be lower. On the other hand, if the rolls are too long or if there is not enough product to fill the container, then the cost per unit will be increased.

3. Technical Specifications of Geomembrane HDPE 2 mm

The 2 mm HDPE liner is an engineering-grade product of top quality that complies with the requirements of GMB/GMT standards (ASTM, GRI-GM13).

3.1 Geomembrane HDPE 2 mm Physical Properties

Property | Typical Value |

Thickness | 2.0 mm |

Density | ≥ 0.94 g/cm³ |

Tensile Strength | 28–36 MPa |

Elongation at Break | ≥ 700% |

Tear Resistance | Very High |

Puncture Resistance | Extremely High |

Water Permeability | 0 (Impermeable) |

3.2 Chemical Resistance

Geomembrane hdpe 2 mm is chemically really resistant, so it may be used in a huge number of industrial and environmental applications.

3.2.1 Resistant to Industrial Chemicals

The geomembrane liner is capable of resisting chemical attacks from a multitude of harsh chemicals that are typical of the mining, industrial waste, and chemical storage sectors without any noticeable degradation, thus it maintains stable containment over the long term.

3.2.2 Resistant to Acids, Alkalis, and Hydrocarbons

The hdpe geomembrane keeps all of its physicochemical characteristics while being exposed to concentrated acids, bases, and hydrocarbons, which essentially rules out the occurrence of leaks or failure of the material in such environments.

3.2.3 Compatible with Wastewater, Leachate, and Aggressive Liquids

Apart from that, 60 mil hdpe liner is perfect for landfills leachate ponds, wastewater treatment lagoons, and chemical storage basins, where it can contribute to environmental safety and make it easier to obey the regulations.

3.3 UV & Weather Resistance

2 mm geomembrane sheet is made to perform outside for a long time and can take even extreme weather conditions.

3.3.1 Designed for Outdoor Long-Term Applications

Excellent resistance to heat, rain, and freeze-thaw cycles are some of the features that allow it to retain its flexibility and still be impermeable regardless of the weather.

3.3.2 High Carbon Black Content for UV Protection

Carbon black addition to the product prevents the material deterioration, and thus the extension of the life of the liner, due to UV rays which are blocked by it when exposed to the sun.

3.3.3 Service Life: 50 to 100 Years (Under Conditions of Proper Installation)

After decades of use and under the right conditions, on well-prepared subgrades, this membrane will continue to perform well and provide safety with minimum maintenance costs and risks to the environment.

4. High-Quality Geomembrane HDPE 2 mm Brings Ultimate

4.1 Safety and Security

By selecting a top 2 mm hdpe membrane, a user can be sure of the heat, waterproof and UV resistance performance of the 2 mm high-density polyethylene geomembrane throughout any engineering and environmental projects of major significance.

4.2 Durability

Polished hdpe geomembrane liner can retain their tensile strength and elastic ability for 20 years or more even under the influence of heavy loads, strong acids and bases, and exposure to temperature changes thus, they are very reliable for total containment over their service life.

4.3 Ecological Regulations

Implementing airtight hdpe geomembrane sheet solutions that comply with both local and international regulations help safeguard ecosystems from contamination of the underground water and soil while ensuring that the projects are managed sustainably.

4.4 Reduction of Lifetime Operation Costs

A 4 mm PVC geomembrane will cost you less from the very beginning than a premium impermeable geomembrane but the latter will eventually be less costly in maintenance and operation due to increased reliability of the system and fewer repair works or replacements required.

4.5 Impermeability That Can Be Trusted for Critical Projects

The high-quality hdpe liner sheet act as a perfect shield against liquid, leachate, and chemical penetration, thus, guaranteeing safety and performance in risk-intensive sectors such as mining, landfill containment, industrial wastewater management, and large-scale water reservoirs.

This product is an absolutely indispensable geosynthetics material for the industry sector and all sorts of projects which are characterized by extreme demand for durability, environmental safeness, and reliability over the long-term.

5. FAQ - Harga Geomembrane HDPE 2 mm

Q1: What is HDPE Geomembrane 2 mm used for?

A: A 2 mm HDPE geomembrane is the most common solution for a lining system in new landfills,cover is the first choice when it comes to mining pads, reservoir for water, irrigation pond, and tanks for chemicals or wastewater pollution control in the industry. Due to its great thickness it offers excellent anti-pyunt and anti-tear qualities thereby being compatible in heavy contention projects with a long period of the containment of the earth surface factory or the like application area.

Q2: How long does HDPE 2 mm geomembrane last outdoors?

A: As long as the material used is of top-notch quality and is correctly installed, the service period shall be somewhere between 50 and 100 years. Carbon black protects the product from UV, while the high-density polyethylene keeps the product stable against temperature changes, weather, and mechanical stress.

Q3: What is the best method to keep HDPE geomembrane in good shape after putting it in place?

A: The upkeep is almost non-existent:

Inspection for punctures, tears, or seam damage should be part of the regular checks.

The limiter should be protected against possible hacks or sharp tools abrasively dragged over the surface.

Ensure cleaning to make sure there is no buildup causing localized stress areas.

Good quality liners are almost without the need for the same upkeep which makes them a good choice in terms of cost over a long period.

Q4: Is it possible for the liner to operate in either cold or tropical climates?

A: Certainly. HDPE geomembranes are adaptable to a broad spectrum of temperatures. They can sustain their properties both in freezing situations and hot tropic environments when installation was done properly.

Conclusion

This film made of HDPE 2 mm offers exceptional versatility, robust resistance to chemicals, and complete waterproofness that turns it into a perfect solution for landfills, haling of unused materials of mining, water reservoirs, industrial areas, and aquatic farming projects. The long-term sustainability of the eco-friendly processor, as well as a cost-saving maintenance practice, can be guaranteed if one chooses quality materials.

For a dependable output that meets the highest engineering benchmarks, The Best Project Material Co., Ltd.(BPM Geosynthetics)is your source of top-notch 2 mm HDPE geomembrane that is not only of unvarying quality but also offers the flexibility of customization along with worldwide delivery support. Making BPM Geosynthetics your reliable partner in all heavy-load containment works.