Top 7 Advantages of HDPE Pond Liner for Landfills

HDPE Pond Liner is a kind of geomembrane made from magnificent high-density polyethylene (HDPE). It is manufactured the usage of a one-of-a-kind formula of virgin polyethylene resin, carbon black, antioxidants, anti-aging agents, and UV resistance components. These components decorate the liner’s resistance to UV radiation, making it appropriate for uncovered conditions.

HDPE Pond Liner are regarded for their sturdiness and capacity to stand up to greater temperatures, extending their provider life. HDPE liner provide a low cost answer for containment functions due to their low cost, extremely good chemical resistance, and weathering properties.

The easy HDPE pond liner is extensively used in quite a number industries such as water conservancy, petrochemicals, agriculture, and aquaculture, thanks to its anti-aging and water-resistant properties. It meets the necessities set with the aid of the GRI-GM13 Specification trendy for HD Geomembrane pond Liner, making sure its fantastic and performance.

High-Density Polyethylene (HDPE) geomembrane pond liner have turn out to be the gold trendy for landfill lining structures due to their unmatched durability, chemical resistance, and impermeability. Landfills require long-term containment options to forestall leachate—a poisonous byproduct of decomposing waste—from contaminating soil and groundwater. HDPE pond liners furnish a robust, cost-effective, and environmentally protected solution.

This article explores the pinnacle 7 aspects of HDPE pond liner that make them perfect for landfill applications, supported by way of real-world case studies, technical data, and comparative analysiswith choice substances like PVC, LLDPE, and EPDM.

1. HDPE Pond Liner for Landfills – Superior Chemical Resistance

Landfill leachate is a complicated and exceedingly aggressive liquid containing acids, natural solvents, heavy metals, salts, and hydrocarbons. Over time, these supplies can penetrate or degrade weaker lining materials, main to leakage and environmental contamination.

High Density Polyethylene liner is broadly used in landfill containment structures due to the fact of their terrific chemical resistance. Unlike PVC or LDPE liner, HDPE continues its structural integrity even underneath extended publicity to harsh chemical environments, making sure long-term overall performance and environmental safety.

1.1 HDPE Pond Liner for Landfills - Technical Data

1.1.1 HDPE Pond Liner for Landfills - Chemical Resistance Profile, Resistant to:

- Acids (pH 1–14) – Suitable for most acidic and alkaline prerequisites located in leachate.

- Hydrocarbons – Resists degradation from petroleum merchandise such as benzene, diesel, and gasoline.

- Salts, alcohols, and oxidants – Performs properly towards more than a few industrial and natural compounds.

1.1.2 HDPE Pond Liner for Landfills - Not endorsed for:

- Strong oxidizing acids – e.g., focused nitric acid, which can harm the polymer over time.

- Certain fragrant hydrocarbons – Long-term publicity to unique high-aromatic solvents might also minimize provider life.

These homes make HDPE pond liner an best preference for landfill base liners, capping systems, and leachate ponds.

1.2 HDPE Pond Liner for Landfills Case Study: Landfill in Lima, Peru

In Lima, Peru, a giant municipal landfill skilled repeated liner screw ups due to acidic leachate attacking the beforehand hooked up 1.2 mm PVC liner. Within solely 3–5 years, the PVC fabric grew to become brittle and developed cracks, main to leachate leakage and highly-priced repairs.

In 2013, the landfill administration switched to 1.5 mm HDPE liner for the base and leachate series areas. The HDPE liner was once particularly chosen for its most suitable resistance to acidic and hydrocarbon-rich leachate.

After 10 years of non-stop operation, inspections published that the HDPE liner:

- Retained over 95% of its tensile strength

- Showed no seen signs and symptoms of stress cracking or chemical degradation

- Maintained full impermeability, stopping similarly environmental contamination

This case surely demonstrates HDPE’s long-term sturdiness and its suitability for difficult landfill applications.

1.3 Comparison of HDPE Pond Liner for Landfills with other liners

Material | Chemical Resistance | Lifespan in Landfills |

HDPE | Excellent | 50+ years |

PVC | Moderate | 10–20 years |

LLDPE | Good | 20–30 years |

EPDM | Poor (swells in oils) | 15–25 years |

2. HDPE Pond Liner for Landfills - Excellent Impermeability (Low Permeability Coefficient)

One of the most integral features of a landfill or waste containment liner is to stop leachate from migrating into surrounding soil and groundwater. HDPE Liner Sheet provide magnificent impermeability, with a permeability coefficient of ≤ 1 × 10⁻¹³ cm/s. This ultra-low permeability ensures that unsafe contaminants stay entirely contained inside the targeted area, safeguarding environmental and public health.

2.1 HDPE Pond Liner for Landfills Technical Data

2.1.1 HDPE Pond Liner Permeability Performance:

- Permeability coefficient: ≤ 1 × 10⁻¹³ cm/s – amongst the lowest of all artificial liners.

- Performance comparison: Up to a hundred instances decrease permeability than compacted clay liners, which normally have coefficients of 1 × 10⁻⁷ to 1 × 10⁻⁹ cm/s.

- Leachate retention: Zero detectable leakage when suitable established with welded seams and examined for integrity.

2.1.2 HDPE Pond Liner Environmental Benefit:

- HDPE Pond Liner Reduces chance of groundwater contamination.

- HDPE Pond Liner Minimizes poisonous seepage into surrounding ecosystems.

- HDPE Pond Liner Meets or exceeds global landfill containment requirements (e.g., EPA Subtitle D in the USA).

2.2 HDPE Pond Liner for Landfills - Case Study: Mining Waste Containment in Arequipa, Peru

In Arequipa, Peru, a copper mining operation confronted challenges in containing poisonous tailings that blanketed heavy metals, acids, and technique chemicals. The authentic clay-based containment device used to be inclined to micro-seepage, threatening close by rivers.

In 2018, the corporation changed the machine with a geomembrane HDPE 2mm established throughout the tailings storage facility. Key measures included:

- Double-welded seams for most sealing.

- Quality assurance trying out the usage of air strain and vacuum field methods.

- Protective geotextile underlay to forestall punctures.

Post-installation hydrogeological monitoring over three years confirmed:

- Zero detectable leakage into groundwater.

- Stable liner overall performance no matter publicity to acidic waste.

- No measurable infection in downstream water sources.

This task grew to become a mannequin for environmentally responsible mining waste containment in South America.

2.3 Comparison HDPE Pond Liner with Alternative Barriers

Barrier Type | Permeability (cm/s) | Cost per m² |

HDPE | ≤1×10⁻¹³ | $5–$10 |

Compacted Clay | 1×10⁻⁷ | $3–$6 |

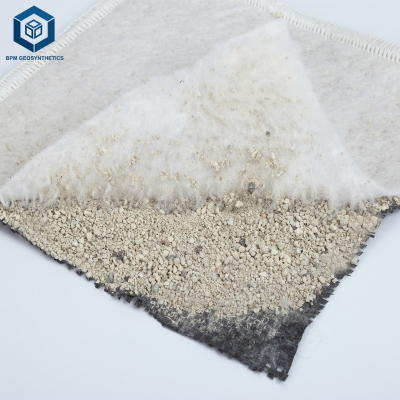

GCL (Bentonite) | 1×10⁻⁹ | $4–$8 |

Conclusion: HDPE Pond Liner provides the best balance of cost and impermeability for landfills.

3. HDPE Pond Liner for Landfills - High Tensile Strength & Puncture Resistance

Landfill environments expose liners to severe mechanical stress, along with heavy waste compaction, contract of waste masses, and contact with sharp particles such as metal, glass, and development rubble. A susceptible liner can puncture or tear, main to instant leachate leakage.

HDPE geomembrane excel in these prerequisites due to their excessive tensile energy (≥ 20 MPa) and extraordinary puncture resistance. These mechanical homes permit HDPE liner to keep integrity even below excessive load and have an effect on conditions, considerably extending carrier life.

3.1 HDPE Pond Liner for Landfills Technical Data

3.1.1 HDPE Pond Liner Mechanical Performance:

- Tensile Strength: 20–35 MPa (ASTM D638) – resists stretching and tearing underneath load.

- Puncture Resistance: Up to five hundred N or greater relying on thickness and specification (ASTM D4833).

- Elongation at Break: 700–900% – allows deformation except rupture at some point of landfill settlement.

- Impact Resistance: Withstands falling sharp particles except perforation when mixed with defensive geotextile layers.

3.1.2 HDPE Pond Liner Design Considerations:

- Thicker liners (e.g., 2 mm) provide substantially higher puncture resistance.

- The use of a geotextile cushion layer under the liner in addition reduces puncture chance from subgrade rocks or debris.

- Reinforced HDPE alternatives grant better tear resistance for high-load areas such as tipping zones.

3.2 HDPE Pond Liner for Landfills Case Study: Landfill Expansion in Trujillo, Peru

In Trujillo, a municipal landfill growth required a lining device that should undergo non-stop heavy equipment operation for waste compaction and spreading. The venture engineers special bolstered two mm HDPE liners with protecting nonwoven geotextile underlayers.

3.2.1 HDPE Pond Liner for Landfills Key Installation Measures:

- Double-welded seams with non-destructive trying out for seam integrity.

- Strategic placement of thicker liners in high-traffic tipping areas.

- Geotextile underlay to take in factor masses from sharp debris.

3.2.2 HDPE Pond Liner for Landfills Performance Results after 5 Years:

- No punctures or tears recorded all through activities inspections.

- Landfill Liner maintained full impermeability in spite of repeated compaction passes through 30-ton loaders.

- Settlement zones confirmed no loss of mechanical energy or stress cracking.

This assignment verified that accurate distinct and set up HDPE Landfill liner can face up to a long time of heavy mechanical stress, making them best for disturbing landfill operations.

3.3 HDPE Pond Liner for Landfills Puncture Test Comparison

Material | |

HDPE (1.5mm) | 300 N |

PVC (1.5mm) | 200 N |

LLDPE (1.5mm) | 250 N |

Key Takeaway: Thicker HDPE (≥2.0mm) is best for high-stress landfills.

4. HDPE Pond Liner for Landfills - UV & Weather Resistance

In many landfill projects, components of the liner machine stay uncovered to sunlight, rainfall, and excessive temperature fluctuations for years earlier than closing cowl placement. Without suitable UV protection, polymer liners can go through from photo-oxidation, main to floor cracking, loss of flexibility, and decreased tensile strength.

HDPE geomembrane is formulated with 2–3% carbon black, which acts as a effective UV stabilizer. This additive absorbs dangerous ultraviolet rays and prevents polymer chain degradation, enabling the liner to stand up to long-term out of doors publicity in harsh climates. Additionally, HDPE’s thermal balance approves it to keep mechanical homes throughout a broad temperature vary (-60°C to +60°C), making it appropriate for desert, tropical, and high-altitude environments.

4.1 HDPE Pond Liner for Landfills Technical Data

4.1.1 HDPE Pond Liner UV Resistance Features:

- Carbon Black Content: 2–3% (ASTM D4218) for best UV absorption.

- UV Resistance Retention: > 90% tensile electricity retention after 8,000 hours of accelerated UV weathering (ASTM G154).

- Thermal Stability: Maintains flexibility and tensile homes in intense bloodless and heat.

- Oxidative Induction Time (OIT): 100–150 minutes (ASTM D3895), indicating sturdy resistance to oxidation from warmth and UV.

4.1.2 HDPE Pond Liner Weathering Advantages:

- Resists cracking from thermal biking between warm days and bloodless nights.

- Stable in opposition to acid rain and atmospheric pollutants.

- Suitable for everlasting publicity in some containment functions (e.g., stormwater ponds, evaporation basins).

4.2 HDPE Pond Liner for Landfills - Case Study: Open Landfill in Piura, Peru

4.2.1 HDPE Pond Liner for Landfills Project Background:

Piura, placed in northern Peru, experiences one of the best UV indexes in South America and usual seasonal rainfall. An open municipal landfill required a liner that should stay uncovered for quite a few years earlier than capping due to phased waste telephone filling.

4.2.2 HDPE Pond Liner for Landfills Solution:

UV-stabilized 1.5 mm HDPE geomembrane with 2.5% carbon black content material used to be installed. The venture additionally included:

- Anchored edges to forestall wind uplift.

- Regular inspections each and every six months to reveal floor condition.

- Protective cowl soils utilized in executed sections.

Performance After eight Years:

- Retained over 90% of authentic tensile electricity and elongation.

- No seen floor cracking, chalking, or embrittlement.

- Maintained impermeability, with no recorded leachate seepage.

This case illustrates that appropriate formulated HDPE liner with UV stabilizers can maintain long-term publicity in high-radiation environments besides sizable degradation.

4.3 HDPE Pond Liner for Landfills UV Degradation Comparison

Material | Lifespan (Exposed) |

HDPE (UV-stabilized) | 30+ years |

PVC | 10–15 years |

LLDPE (non-stabilized) | 5–8 years |

Recommendation: Always use carbon-black HDPE for exposed landfill applications.

5. HDPE Pond Liner for Landfills - Flexibility & Stress Crack Resistance

Landfills are dynamic structures. Over time, settling of waste masses, floor subsidence, and seasonal soil motion can purpose liners to deform. In seismic zones, unexpected floor shifts from earthquakes can impose extra strain.

If a geomembrane is too inflexible or has terrible crack resistance, it may additionally enhance stress cracks—microscopic fractures that can propagate and compromise the liner’s impermeability.

Landfill Liner Material is engineered with balanced flexibility and excessive stress crack resistance, permitting them to face up to repeated deformation besides loss of integrity. Proper resin selection, manufacturing control, and enough elongation at wreck allow geomembrane liner landfill to adapt to floor motion whilst retaining performance.

5.1 HDPE Pond Liner for Landfills Technical Data

5.1.1 HDPE Pond Liner Key Mechanical Properties:

- Stress Crack Resistance: ≥ five hundred hours (ASTM D5397 – Notched Constant Tensile Load test).

- Elongation at Break: 700–900% – permits considerable stretching earlier than rupture.

- Flexibility Range: Performs in temperatures from -60°C to +60°C except embrittlement.

- Tear Resistance: High tear propagation resistance ensures minor floor cuts do now not amplify below stress.

5.1.2 Advantages in Dynamic Conditions:

- Prevents crack initiation in areas of differential settlement.

- Absorbs pressure from cyclic loading due to heavy tools and waste compaction.

- Maintains impermeability in earthquake-prone regions.

5.2 HDPE Pond Liner for Landfills Case Study: Earthquake-Prone Landfill in Ica, Peru

5.2.1 HDPE Pond Liner for Landfills Project Context:

Ica, positioned in southern Peru, is inside a excessive seismic exercise zone. The municipal landfill required a lining device that should undergo each gradual floor agreement and unexpected seismic shocks barring failure.

5.2.2 HDPE Pond Liner for Landfills Solution:

The engineering group chosen 1.5 mm HDPE geomembrane manufactured with a resin mixture in particular designed for excessive Environmental Stress Crack Resistance (ESCR). Additional measures included:

- Installing a clean HDPE liner in base areas for most elongation capacity.

- Placing nonwoven geotextile cushions under the liner to buffer subgrade irregularities.

- Conducting satisfactory manage checks on-site to verify ASTM D5397 compliance.

5.2.3 HDPE Pond Liner for Landfills Performance Outcome:

Following two minor earthquakes (magnitude 5.6 and 6.1) over a 4-year period:

- No seen cracks or tears have been detected throughout post-event inspections.

- Liner seams remained a hundred percent intact with no loss of impermeability.

- Settlement zones confirmed solely minor, non-critical floor rippling besides structural damage.

This case highlights that accurate special Bottom Liner Landfill with excessive ESCR are necessary for landfill initiatives in geologically lively areas, making sure long-term containment even below difficult floor motion conditions.

5.3 HDPE Pond Liner for Landfills Flexibility Test Data

Material | Elongation at Break (%) |

HDPE | 700% |

PVC | 300% |

EPDM | 500% |

6. HDPE Pond Liner for Landfills Long Lifespan (50+ Years)

Landfill containment structures are designed for multi-decade environmental protection, as waste decomposition and leachate era can proceed for 30–50 years or longer after closure. A dependable liner should consequently continue its mechanical strength, chemical resistance, and impermeability over the lengthy term, even underneath regular publicity to leachate, floor pressure, and environmental conditions.

HDPE geomembrane is diagnosed for their amazing provider life, with laboratory growing older research and subject overall performance statistics displaying lifespans exceeding 50 years when true specified, installed, and maintained. This durability is done through:

- High resistance to chemical degradation from acids, bases, and hydrocarbons.

- UV stabilization with 2–3% carbon black for uncovered applications.

- Outstanding oxidative stability, slowing polymer breakdown over time.

- High stress crack resistance, stopping failure below long-term static loads.

6.1 HDPE Pond Liner for Landfills Technical Data

- Predicted Service Life: 50–100 years (based on EPA and Geosynthetic Research Institute studies).

- Oxidative Induction Time (OIT): 100–150 minutes, indicating sturdy resistance to thermal-oxidative degradation.

- Strength Retention: >80% tensile power after 20 years of area publicity in reasonable climates.

- Creep Resistance: Minimal deformation below long-term static load, preserving liner integrity.

6.2 HDPE Pond Liner for Landfills Case Study: Oldest HDPE Liner in Chile (Similar Climate to Peru)

In 1993, a municipal landfill in northern Chile—sharing comparable semi-arid, high-UV local weather prerequisites with components of coastal Peru—installed a 1.5 mm clean HDPE liner for its base and leachate pond. At the time, HDPE used to be nonetheless viewed new for landfill functions in South America.

6.2.1 HDPE Pond Liner for Landfills Performance Evaluation:

- After 30 years in operation, a complete inspection and fabric sampling application was once conducted:

- Tensile Strength: Retained 88% of authentic value.

- Elongation at Break: Maintained above 700%, indicating no embrittlement.

- Chemical Resistance: No seen symptoms of leachate-induced cracking or degradation.

- Impermeability: Permeability remained under 1 × 10⁻¹³ cm/s.

The liner’s overall performance passed expectations, validating that Landfill Plastic Liner can supply a long time of dependable containment in South American climates when accurate hooked up and protected.

6.3 HDPE Pond Liner for Landfills Lifespan Comparison

Material | Expected Lifespan |

HDPE | 50+ years |

PVC | 15–25 years |

EPDM | 20–30 years |

Recommendation: For permanent landfills, HDPE liner is the most economical long-term choice.

7. HDPE Pond Liner for Landfills Welding & Seaming Reliability

One of the key blessings of HDPE geomembrane is their capability to be joined the usage of thermal welding techniques. These strategies create homogeneous, leak-proof seams that are frequently enhanced than the liner itself. Proper welding eliminates attainable leakage points, making sure long-term containment overall performance in landfill applications.

7.1 HDPE Pond Liner for Landfills Common Welding Methods:

- Dual Hot Wedge Welding – Produces two parallel seams with an air channel for on-site stress testing.

- Extrusion Welding – Used for element work and repairs, forming robust bonds in tight or complicated areas.

7.2 Advantages of HDPE Pond Liner Welding:

- Seam electricity generally exceeds 90–95% of the mum or dad material.

- Allows non-destructive trying out (NDT) such as air channel stress trying out or vacuum field inspection.

- Performs nicely beneath each mechanical stress and chemical exposure.

7.3 HDPE Pond Liner for Landfills Case Study: Large Landfill in Colombia (Comparable to Peru)

7.3.1 HDPE Pond Liner for Landfills Project Overview:

A 100,000 m² landfill in Colombia, with environmental prerequisites comparable to coastal Peru, required an impermeable base lining machine for leachate control. Engineers specific 1.5 mm HDPE geomembrane with twin warm wedge welding for all predominant seams.

7.3.2 HDPE Pond Liner for Landfills Installation & Quality Control:

- All area seams have been double welded to permit stress channel testing.

- Air strain exams (ASTM D5820) proven no leaks in welded seams.

- Random samples underwent shear and peel electricity testing, all exceeding undertaking specifications.

Post-installation inspection proven a hundred percent seam integrity, making sure a utterly sealed containment system. The aggregate of expert set up and perfect trying out assured zero leakage factors from seaming operations.

7.4 HDPE Pond Liner for Landfills Welding Methods Comparison

Method | Strength | Cost |

Extrusion Welding | Very Strong | High |

Hot Wedge Welding | Strong | Medium |

Adhesive (PVC/EPDM) | Weak | Low |

Best Practice: Always test seams with spark testing or air lance.

8. Conclusion: Why HDPE is the Best Choice for Landfills?

HDPE pond liner is the top choice for landfill applications due to:

- Chemical resistance (handles leachate)

- Impermeability (protects groundwater)

- Puncture resistance (withstands heavy loads)

- UV stability(lasts decades outdoors)

- Flexibility (resists ground movement)

- 50+ year lifespan(cost-effective long-term)

- Strong welding seams(prevents leaks)

For the landfill project in Peru, a 1.5mm to 2.5mm HDPE geomembrane from manufacturer BPM geosynthetics was recommended.