Ultimate Guide to Choosing Landfill Liner Material

Selecting the proper landfill liner material is a quintessential choice in landfill planning and operation, as it acts as the fundamental barrier stopping leachate and contaminants from seeping into soil and groundwater. Project consumers and engineers have to consider quite a number geosynthetic and geotechnical materials—such as HDPE geomembranes, clay liners, geosynthetic clay liners (GCLs), and composite liners—considering elements like permeability, chemical resistance, durability, and ease of installation. Choosing the fabulous landfill liner now not solely ensures regulatory compliance however additionally minimizes operational risks, protection costs, and environmental impact.

This complete information ambitions to supply a step-by-step strategy for deciding on the most appropriate HDPE landfill liner. From evaluating material homes to grasp regulatory necessities and set up considerations, this article equips challenge managers, engineers, and clients with sensible insights to make confident, knowledgeable choices for long-lasting landfill protection and sustainability.

1. Landfill Liner Material Selection

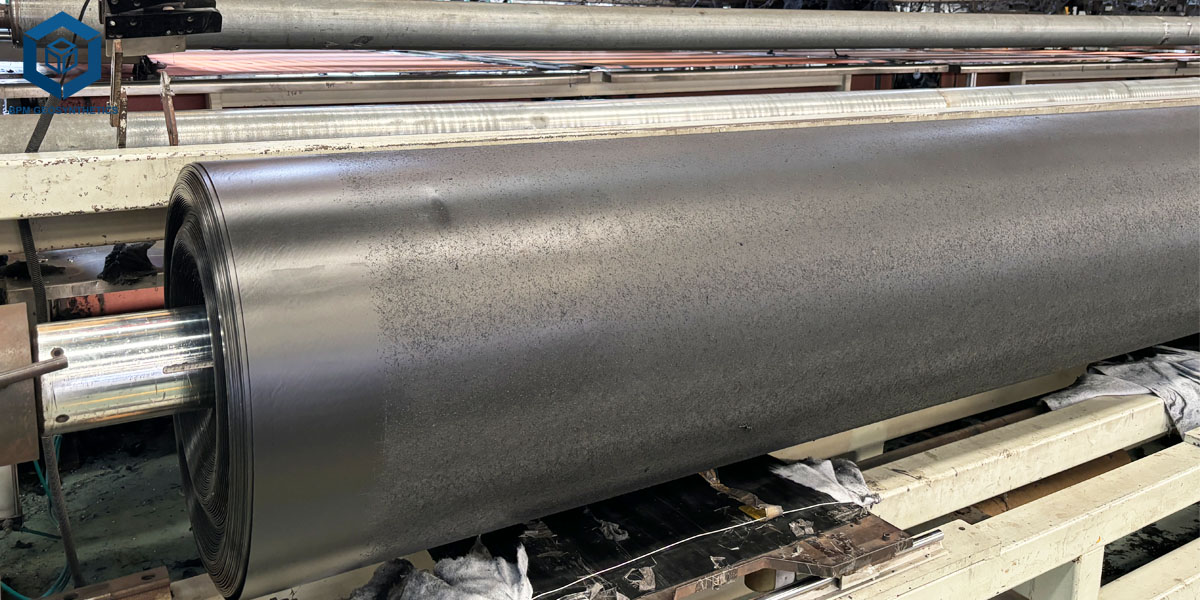

High density polyethylene HDPE geomembrane is broadly identified as the most dependable anti-seepage material for landfills due to its most excellent physical, chemical, and mechanical properties. Its major blessings include:

1.1 Landfill Liner Material - Excellent Anti-Seepage Performance

HDPE’s excessive molecular density offers it extraordinarily low permeability, making its leakage prevention a long way most effective to regular substances like clay liner or PVC liner, and making sure tremendous containment of landfill leachate whilst defending surrounding soil and groundwater.

1.2 Landfill Liner Material - Outstanding Chemical Resistance

HDPE geomembrane liner landfill is fairly resistant to chemical substances such as sturdy acids, alkalis, and natural solvents many times located in landfill leachate, keeping steadiness besides reacting or degrading to make sure long-term reliability in harsh landfill environments.

1.3 Superior Mechanical Properties

The material liner presents notable tensile energy and puncture resistance whilst final flexible, permitting it to face up to uneven basis settlement, conform to irregular surfaces, and decrease the danger of cracks or tears all through installation.

1.4 High Durability and Longevity

HDPE landfill liner system comprise anti-ultraviolet (UV) components and antioxidants to forestall degradation from daylight for the duration of installation, and when buried underground, they can supply long-term containment with a provider lifestyles of up to 50 years and minimal maintenance.

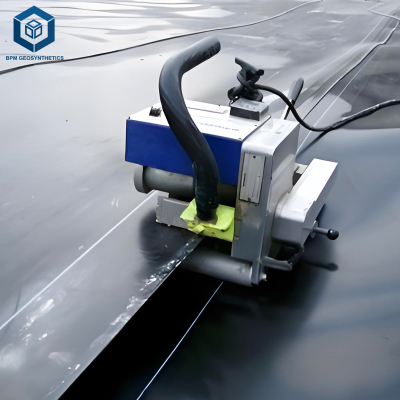

1.5 Landfill Liner Material Ease of Installation and Maintenance

HDPE geomembrane sheets are light-weight and flexible, permitting for handy on-site welding to structure a continuous, seamless liner and making dealing with and deployment greater environment friendly than choice materials.

2. Landfill Liner Material Thickness Selection

The thickness of HDPE geomembrane need to be chosen in accordance to the unique characteristic and place inside the landfill. Correct thickness ensures superb seepage control, mechanical stability, and long-term durability.

2.1 Bottom Anti-Seepage Layer

- Recommended thickness: ≥ 1.5 mm

- Recommended width: ≥ 6 meters

- Purpose: Serves as the important barrier between landfill waste and the herbal soil, correctly stopping leachate from contaminating groundwater.

- Why thickness matters: Thicker plastic liner landfill sheets grant higher puncture and tear resistance, which is indispensable as heavy equipment and waste placement can motive injury at some point of construction.

- Additional considerations: Wider liner system in landfill decrease the range of welding seams, reducing the hazard of leakage at joint points. Careful seam welding and fine assessments are quintessential to make sure long-term reliability.

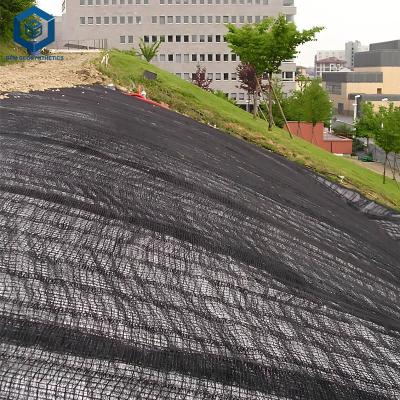

2.2 Slope / Sidewall Anti-Seepage Layer

- Recommended thickness: ≥ 1.5 mm

- Material preference: Rough-surfaced hdpe pond liner to make bigger friction.

- Purpose: Stabilizes the liner on inclined surfaces and prevents slippage of the liner or overlying soil.

- Why hard surface: The textured floor improves friction with soil or geotextile layers, improving slope steadiness and decreasing the hazard of sliding beneath landfill load.

- Additional considerations: Proper anchoring at the pinnacle and backside of slopes is necessary. Inspection after set up ensures that wrinkles or folds do no longer compromise anti-seepage performance.

2.3 Temporary Covering Layer

- Recommended thickness: ≥ 0.5 mm

- Purpose: Provides temporary insurance to minimize scent emissions, forestall flying debris, and restriction publicity of waste to rain and wind at some stage in development or intervening time storage.

- Why skinny sheets are used: Lighter hdpe geomembrane is less complicated to handle, deploy, and remove, making them realistic for transient use except heavy equipment.

- Additional considerations: Even even though temporary, care must be taken to keep away from tears at some stage in windy conditions. Overlapping sheets precise ensures full coverage.

2.4 Landfill Covering Layer (Final Cap)

- Recommended thickness: ≥ two mm

- Purpose: Serves as the long-term protecting layer for achieved landfills, bettering puncture resistance, anti-aging, and UV durability.

- Why thickness matters: A thicker geomembrane pond liner cap withstands mechanical stress, weathering, and workable contract of the waste beneath over decades.

- Additional considerations: Installation need to think about drainage and vegetation layers if phase of a inexperienced cowl system. Regular inspection ensures integrity over the landfill’s operational lifetime.

3. Characteristics of Landfill Liner Material

HDPE geomembrane is a polymer-based movie extensively used in landfill tasks due to its notable anti-seepage performance, chemical resistance, and long-term durability. Its key traits include:

3.1 Excellent Anti-Seepage Performance

Landfill plastic liner has an extraordinarily low permeability coefficient, making it noticeably tremendous at stopping drinks such as water, leachate, and different chemical waste from seeping into the surrounding soil.By forming a non-stop barrier, it protects groundwater and soil from contamination, making sure compliance with environmental regulations.Its seamless set up thru on-site welding minimizes achievable leak points, in addition improving its containment effectiveness.

This property is mainly necessary for landfills coping with hazardous or industrial waste, the place strict environmental safety is mandatory.

3.2 Chemical Corrosion Resistance

HDPE is notably resistant to a huge range of chemical substances, such as acids, alkalis, salts, and natural solvents often observed in landfill leachate.This resistance ensures that the geomembrane sheet continues secure anti-seepage overall performance over lengthy periods, even underneath harsh chemical exposure.It reduces the danger of polyethylene pond liners degradation, corrosion, or failure, which ought to lead to environmental illness or steeply-priced repairs.

This makes hdpe geomembrane pond liner appropriate for municipal, industrial, and hazardous waste landfills.

3.3 Aging Resistance

HDPE liner pond famous superb climate resistance and anti-UV properties, permitting it to be uncovered exterior for prolonged intervals barring considerable degradation.When buried underground, its carrier lifestyles can attain numerous decades, keeping long-term containment and decreasing renovation needs.The fabric additionally resists oxidation and thermal aging, making sure overall performance steadiness below a number local weather conditions.

This property is quintessential for landfill capping and long-term environmental safety.

3.4 Easy Construction and Adaptability

HDPE high density polyethylene liner is lightweight, flexible, and effortless to bend, making it handy for transportation, handling, and on-site installation.Its adaptability lets in it to conform to uneven terrain, slopes, and complicated landfill geometries barring compromising anti-seepage performance.On-site welding permits the advent of a continuous, seamless liner, lowering the chance of leakage at joints.

The ease of building helps shop labor and time whilst making sure extremely good installation, even in difficult environments.

4. Application of Landfill Liner Material

In current landfills, HDPE geomembranes and different landfill plastic liner substances are specifically used to assemble anti-seepage layers that forestall leachate from contaminating soil and groundwater. Their functions include:

4.1. Bottom Anti-Seepage Layer

A layer of high density polyethylene geomembrane is laid at the backside of the landfill to structure a whole anti-seepage barrier, which correctly prevents leachate from penetrating into the ground.

- Purpose: Prevents leachate from penetrating into the soil and groundwater, making sure environmental protection.

- Additional benefits: Provides a steady basis for waste placement and reduces the threat of subsurface contamination.

- Considerations: Thickness and first-class of the hdpe landfill liner are critical, and acceptable welding is required to make sure seamless coverage.

4.2. Slope Anti-Seepage Layer

A polyethylene geomembrane is laid on the slope of the landfill to stop rainwater from eroding rubbish and leaking leachate.

- Purpose: Prevents rainwater from at once contacting and eroding the waste, decreasing the era of leachate and minimizing floor runoff.

- Additional benefits: Enhances slope steadiness by using decreasing water infiltration and viable sliding of the waste mass.

- Considerations: Rough-surfaced geomembranes are desired on slopes to amplify friction and forestall slippage. Proper anchoring at the pinnacle and backside of slopes is necessary.

4.3. Covering Layer (Landfill Cap)

A layer of hdpe channel lining is protected on the floor of the landfill to stop rainwater from at once eroding rubbish and decreasing the technology of leachate. At the equal time, the protecting layer can additionally play a function in warmth renovation and moisture retention, and promote the stabilization of garbage.

- Purpose: Prevents direct rainwater infiltration, reduces leachate generation, and protects the landfill floor from erosion.

- Additional benefits: Acts as a thermal and moisture barrier, advertising waste stabilization and lowering scent emission. Supports vegetation increase in inexperienced cowl structures for environmental restoration.

- Considerations: The overlaying layer need to be thick and long lasting to face up to weathering, UV exposure, and mechanical stress. Proper drainage structures above the liner make certain long-term effectiveness.

5. Quality Inspection of Anti-Seepage Landfill Liner Material

To make sure the reliability, safety, and long-term overall performance of landfill anti-seepage membranes, conducting thorough exceptional inspections earlier than choice and set up is essential. Proper inspection helps affirm fabric performance, pick out achievable defects, and supply self belief in landfill construction. Key factors of inspection include:

5.1 Appearance Inspection

Check the membrane for floor defects such as cracks, holes, scratches, or uneven thickness.

Ensure the floor is easy or textured in accordance to layout requirements, as floor fantastic influences set up and seepage performance.

5.2 Thickness Measurement

Verify that the hdpe smooth geomembrane meets the designated thickness for exceptional landfill layers (bottom, slope, cover, temporary).

Uniform thickness ensures constant anti-seepage overall performance and reduces the hazard of leakage at vulnerable points.

5.3 Mechanical Properties

Tensile strength: Confirms the membrane can face up to mechanical stress in the course of set up and landfill operation.

Elongation: Ensures flexibility and adaptability to uneven terrain, settlement, and slope deformation.

5.4 Chemical Resistance

Test the geomembrane’s resistance to acids, alkalis, salts, and different chemical compounds normally current in leachate.

Guarantees long-term balance and prevents degradation below harsh landfill conditions.

5.5 UV Resistance and Aging

Evaluate the geomembrane’s sturdiness towards daylight exposure, oxidation, and thermal aging.

Ensures the cloth keeps overall performance in the course of storage, installation, and long-term service.

5.6 Additional Considerations

On-site inspections might also encompass seam exceptional testing, welding strength, and puncture resistance.

Documenting inspection outcomes affords traceability and assurance that the chosen membrane meets regulatory and project-specific requirements.

By performing complete first-rate inspections, engineers and consumers can pick out membranes with tested performance, making sure the effectiveness, safety, and sturdiness of landfill anti-seepage systems.

6. Environmental Safety and Security Precautions

In the method of deciding on and the usage of landfill liner material, we ought to additionally pay interest to environmental safety and protection issues. For used anti-seepage membranes, they must be top dealt with to keep away from secondary air pollution to the environment. At the equal time, for the duration of the development process, we ought to pay interest to security problems and take indispensable shielding measures to make certain the security of development workers.

7. Manufacturer and company selection

When deciding on an anti-seepage membrane, we have to additionally reflect onconsideration on the recognition of the producer and brand. Choosing producers and manufacturers with properly recognition and many years of manufacturing trip can higher assurance the first-rate and reliability of the anti-seepage membrane. At the identical time, conversation and cooperation with producers are additionally very important. We can have in-depth exchanges on unique wants and troubles in order to pick the most appropriate anti-seepage membrane products.

8. Summary

Selecting great landfill liner material is a systematic method that requires thinking about fabric type, performance, thickness, application, producer reputation, and cost. Proper choice ensures mission safety, extends provider life, and improves typical quality. Maintaining verbal exchange with suppliers and looking for expert recommendation is indispensable for knowledgeable decision-making.

In short, selecting the proper HDPE geomembrane entails evaluating its properties, set up requirements, quality, and environmental safety. Reasonable determination and use beautify anti-seepage performance, limit environmental risks, and guide the sustainable improvement of landfill and waste administration projects.

Recommended BPM Geosynthetics

For top notch landfill liner materials, The Best Project Material Co., Ltd. (BPM Geosynthetics)is a relied on choice. BPM specializes in manufacturing HDPE geomembranes and different geosynthetic merchandise with awesome anti-seepage performance, chemical resistance, and durability. Their merchandise meet worldwide standards, help dependable installation, and assist make sure long-term environmental protection. Choosing BPM offers expert guidance, regular quality, and peace of thought for landfill projects.