How to Choose Damliners Irrigation Systems?

Choosing the proper damliners irrigation systems can make all the distinction between environment friendly water administration and steeply-priced leaks. With so many materials, thicknesses, and set up selections available, choosing a liner that ensures durability, flexibility, and long-term overall performance is crucial. In this guide, we’ll destroy down the key elements to assist you choose the ideal damliner for your irrigation project, saving time, money, and resources.

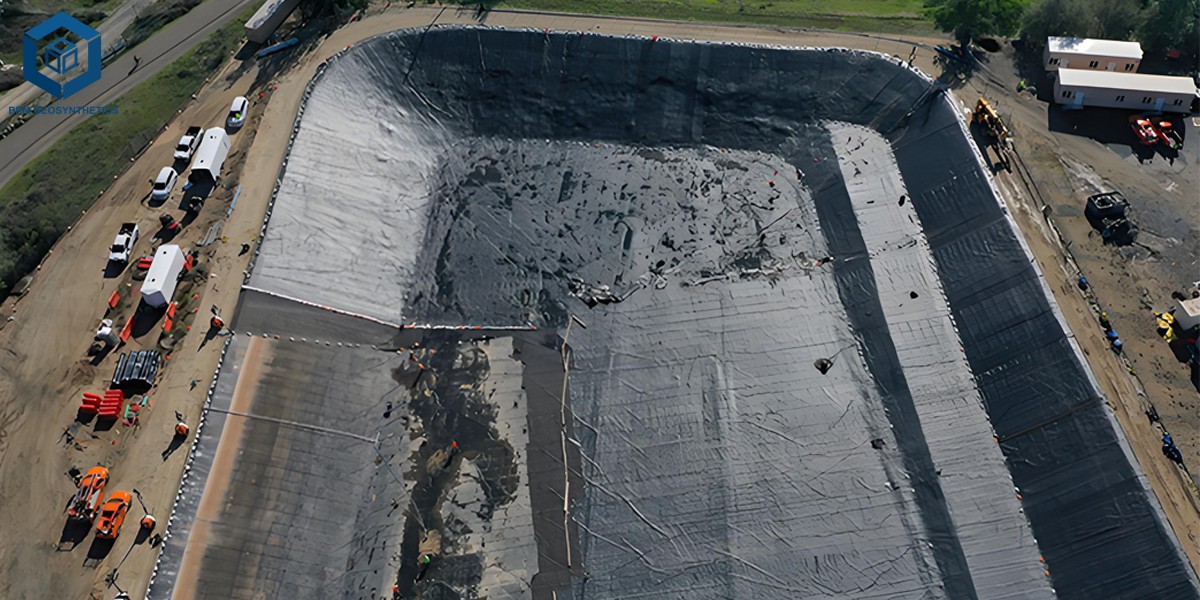

1. What Is Damliners Irrigation Systems?

Dam liners irrigation systems refers to the lining materials used inside or outside the dam, mainly used to prevent water leakage and enhance the stability of the dam body. The use of Dam liners lrrigation systems can improve the overall performance and service life of the dam and promote the sustainable use of water resources.

2. What Are Characteristics of Damliners Irrigation Systems?

Traditional concrete, plastic, and metal containers are costly, have short service lives, and poor anti-seepage effects. Dam liner is high-performance waterproof and leakproof products, especially because of their resistance to chemicals, acids, alkalis, salts, and heavy oils, and good molecular stability. They are used in the chemical and mining industries, and are used for anti-seepage, anti-leakage, and moisture-proof storage locations.

2.1 High Anti-Seepage Performance

Dam liner is bendy water-resistant substances with an extraordinarily excessive anti-seepage coefficient of 1×10⁻¹⁷ cm/s, making sure nearly zero leakage. This makes them best for water retention in irrigation reservoirs, ponds, and different storage systems, imparting long-term reliability.

2.2 Excellent Heat and Cold Resistance

These plastic dam liners can stand up to a broad range of temperatures, from -70℃ in intense bloodless to +110℃ in excessive heat, making them appropriate for various environmental conditions. This temperature resilience ensures steady overall performance at some point of seasonal modifications and harsh climates.

2.3 Strong Chemical Stability

HDPE dam liners face up to corrosion from sturdy acids, alkalis, oils, and different chemicals, making them a especially long lasting anti-corrosion material. This property ensures long-term overall performance even in chemically aggressive environments, such as fertilizer storage or industrial wastewater containment.

2.4 High Tensile Strength

With most fulfilling tensile strength, these dam lining material can suffer mechanical stress and heavy loads, assembly the necessities of high-standard engineering projects. This makes them appropriate for large-scale irrigation dams, reservoirs, and industrial purposes the place sturdiness is essential.

2.5 Outstanding Weather Resistance and Anti-Aging

Pond dam liner characteristic robust climate resistance and anti-aging properties, retaining their overall performance over decades. They can withstand UV radiation, excessive weather, and environmental degradation, making sure long-term reliability for out of doors applications.

2.6 Adaptability to Harsh Conditions

Thanks to excessive tensile power and elongation at break, these dam plastic lining adapt to uneven geological settlements and harsh climates. They preserve integrity below strain, making them perfect for irrigation initiatives in areas with moving soil, slopes, or uneven terrain.

2.7 Safe and Environmentally Friendly Materials

Farm dam liners are made from virgin HDPE and carbon black particles, with no brought preservatives. HDPE is diagnosed as protected for meals packaging and grasp movie applications, reflecting its non-toxic and environmentally pleasant characteristics. This ensures secure water storage and long-term sustainability in irrigation projects.

3. What Scenarios Are Damliners Irrigation Systems Suitable for?

3.1 Damliners Irrigation Systems for Water Conservancy Projects

Damliners are perfect for anti-seepage, plugging, and reinforcement in rivers, lakes, and reservoir dams. They are additionally extensively used for canal lining, vertical core walls, and slope protection, correctly stopping water loss, improving structural stability, and extending the lifespan of hydraulic projects.

3.2 Damliners Irrigation Systems for Municipal Engineering

In city environments, damliners serve as dependable anti-seepage options for subways, underground constructing structures, planted roofs, roof gardens, and sewage pipelines. Their flexibility and sturdiness make sure long-term safety in opposition to water infiltration and structural damage.

3.3 Damliners Irrigation Systems for Gardens and Landscaping

For synthetic water features, Damliners irrigation systems is used in lakes, rivers, reservoirs, golf courses, pond bottoms, slope stabilization, and inexperienced lawns, supplying super waterproofing whilst aiding aesthetic and leisure landscaping designs.

3.4 Damliners Irrigation Systems for Petrochemicals

In the chemical and petrochemical industries, earth dam liners provide excessive chemical resistance for oil storage tanks, chemical response tanks, sedimentation tank linings, and secondary linings, defending towards leaks, spills, and corrosion whilst making sure environmental safety.

3.5 Damliners Irrigation Systems for Mining

PVC dam liners are crucial in mining for washing tanks, heap leaching tanks, ash yards, dissolution tanks, sedimentation tanks, and tailing ponds. They stop seepage of hazardous liquids, decrease environmental contamination, and enhance useful resource healing efficiency.

3.6 Damliners Irrigation Systems for Transportation Facilities

In transportation engineering, hdpe pond liner assist with basis reinforcement for highways and furnish anti-seepage safety for culverts, ensuring secure substructures and prolonging the lifespan of avenue and railway projects.

3.7 Damliners Irrigation Systems for Agriculture

HDPE geomembrane is extensively used in agriculture for reservoirs, ingesting water pools, water storage ponds, and irrigation systems. They make sure water conservation, forestall seepage losses, and guide environment friendly irrigation practices in farms and plantations.

3.8 Damliners Irrigation Systems for Aquaculture

For aquaculture, geomembrane sheet is utilized in intensive fish or shrimp breeding ponds, lining of fish ponds, slope safety for sea cucumber ponds, and different aquaculture tanks, supplying leakproof, safe, and environmentally pleasant options for high-density farming operations.

3.9 Damliners Irrigation Systems for Salt Industry and Environmental Protection

In industrial and environmental applications, high density polyethylene pond liner is used in salt manufacturing ponds, landfills, sewage remedy plants, energy plant regulating ponds, and disposal web sites for industrial or health facility strong waste. They forestall illness of soil and groundwater, assisting sustainability and regulatory compliance.

Damliners irrigation structures cowl a huge vary of industries and scenarios, from water conservancy to agriculture, aquaculture, and environmental protection. Choosing the proper material, thickness, and specifications, and strictly following building standards, ensures long-term anti-seepage overall performance and task reliability.

4. How to Choose Right Dam Liners Irrigation Systems?

Choosing the right Dam liners irrigation systems is a process that requires comprehensive consideration of multiple factors. Here are some suggestions:

4.1. Understand the basic properties of Dam liners lrrigation systems

First of all, it is very important to understand the basic properties of Dam liners irrigation systems. Dam liners irrigation systems are usually made of materials such as polyethylene, and have excellent compression resistance, impermeability, aging resistance and weather resistance. It can effectively prevent the penetration of moisture and other harmful substances in the soil, protect the soil quality and the stability of the structure

4.2. Consider the applicability of Dam liners lrrigation systems

Different types of Dam liners irrigation systems have different characteristics and application areas. For example, some Dam liners lrrigation systems are suitable for road paving, which can effectively prevent moisture in the soil from penetrating into the road structure and improve the service life of the road;

Some Dam liners lrrigation systems are suitable for agricultural irrigation systems, which can prevent excessive evaporation and leakage of water and improve irrigation efficiency. Therefore, when choosing Dam liners lrrigation systems, you need to pay attention to whether its product variety and specifications are rich and whether they can meet the needs of different engineering projects.

4.3. Understand the experience and reputation of Dam liners lrrigation systems manufacturers

Choose an experienced and reputable Dam liners irrigation systems manufacturer. BPM geosynthetics can provide high-quality products and excellent services. In addition, you can also consult experienced engineers or professionals for their advice and recommendations.

4.4. Reference price

Different Dam liners irrigation systems manufacturers will have different price ranges. BPM geosynthetics provides high-quality products and excellent prices. Product prices are usually related to product quality and performance. Comprehensive considerations are required when choosing to avoid focusing only on price and ignoring product quality.

4.5. Construction and maintenance of Dam liners lrrigation systems

Choose suitable Dam liners irrigation systems materials. High-density polyethylene (HDPE) materials are usually recommended. Design a reasonable anti-seepage system based on specific conditions, such as scale, terrain and soil type. Dam liners lrrigation systems play an important role in the anti-seepage application of dams, which not only protects the environment, but also provides safer and more sanitary conditions for aquaculture activities. Choosing the right materials and the right construction methods will greatly improve the use effect of Dam liners lrrigation systems.

5. Summary

Dam liners irrigation systems have a wide range of application scenarios, covering multiple industries and fields. When selecting and using Dam liners irrigation systems, it is necessary to select appropriate materials and specifications according to the specific use environment and requirements, and strictly follow the construction specifications to ensure that it can effectively play its anti-seepage role in the long term.

Choosing the proper damliners for irrigation structures ensures leak-free, durable, and environment friendly water management. For dependable fantastic and performance, The Best Project Material Co., Ltd.(BPM Geosynthetics)presents HDPE damliners best for all irrigation projects.