Ultmate Guide To Geocell Price

1. What is Geocell?

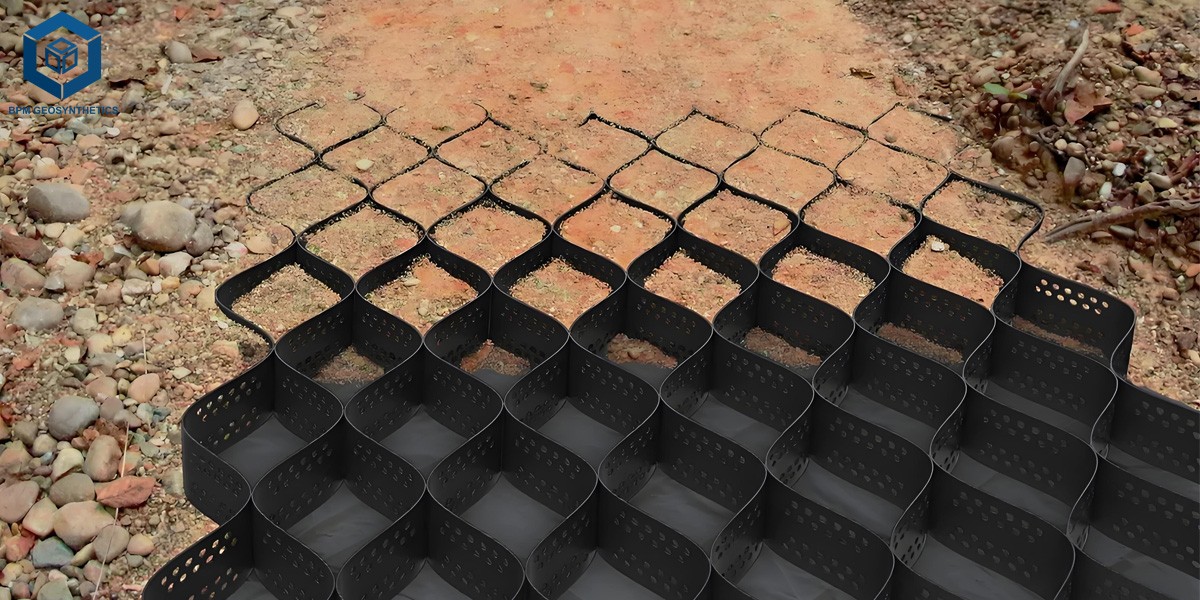

Geocell is a three-dimensional polymer-based geosynthetic material and expandable panels that are used for soil strengthening and erosion control. Geocell material, whose general purpose use is to prevent soil loss that may occur on inclined surfaces due to water and wind, is manufactured in a perforated structure with the aim of rapid drainage and easy compression of the filling material. This material is attached to each other by ultrasonic welding method in the factory environment and the cells that form a honeycomb image when opened are sent to the field in strips.

2. Working Principles of Geocell

Geocell, as a three-dimensional honeycomb covering material, are mainly used for soil stabilization and reinforcement on weak or unstable foundations, such as single-layer road embankments, landslide mitigation, multi-layer retaining walls, and protective fences in various fields. The geometric structure of the grid forms a natural drainage system, which enhances load distribution and prevents soil displacement and erosion caused by external forces such as water flow or wind by confining the fill within interconnected honeycomb structures. The unique design resembles a series of small compartments that securely hold the filling material in place and minimize material loss. Through this approach, it is possible to develop construction methods suitable for ecosystems by filling soil on rock surfaces lacking vegetation. Improving load-bearing capacity is crucial in these applications. In addition, their flexibility allows them to adapt to uneven terrain, providing long-term stability while reducing maintenance costs. The durability and resistance to environmental factors of this material further enhance its effectiveness in civil engineering and landscape beautification projects. Overall, geocell provide an economical, efficient, and sustainable solution for improving soil performance under challenging conditions.

3. What are the Factors Affecting the Geocell Price?

Geocell price is calculated based on the square meter surface area of the material's dimensions when it is opened. The price of geocell is determined by the width, length, and height of the material.

3.1 Types and prices of geocell materials

The raw material cost of Geocell is one of the core factors in pricing. Common materials include HDPE (high-density polyethylene) and PP (polypropylene), which have differences in performance and price. HDPE geocell have higher tensile strength and chemical corrosion resistance, making them suitable for heavy-duty projects such as highways and railway subgrades. Therefore, geocell prices are usually higher than PP. PP material is lighter and more flexible, making it suitable for slope greening and landscape engineering, with relatively lower costs. In addition, some special projects may use modified polymers or recycled materials, and prices may also change accordingly.

3.2. Different geocell specification different geocell price

Geocell Height: such as 50mm, 100mm, 150mm, etc. The larger the height, the more material used and the higher the price.

Welding distance (welding point spacing): The smaller the welding distance, the stronger the structural stability, but the production process is more complex and the geocell price is higher.

Thickness: Usually measured in millimeters(mm), increasing thickness enhances compressive strength but also increases geocell price.

3.3. Geocell Surface treatment

Textured surface treatment: By increasing the surface friction coefficient to improve the anti-skid performance, it is suitable for steep slope reinforcement, but the processing technology will increase the price by 10% to 20%.

UV Stabilized: Adding UV inhibitors can extend the outdoor service life, especially for projects with long-term exposure, and such products are usually more expensive.

Other functions, such as antioxidant and acid alkali resistant coatings, will incur additional costs.

3.4. Different brands and origins result in varying prices for geogrids

Internationally renowned brands such as Tensar and Presto Geosystems generally offer higher prices than local suppliers due to their technology patents and quality management. In addition, imported products need to consider tariffs and transportation costs, while local manufacturing may have a price advantage, but quality consistency needs to be balanced.

4. Application Scenarios and Price Correlation

The price of Geocell is closely related to its application scenarios, and there are significant differences in the demand for material properties, specifications, and procurement models among different engineering types, which directly affect the final cost.

4.1 Infrastructure construction (such as road and railway reinforcement)

High performance requirements: It needs to withstand heavy loads and resist fatigue, usually made of HDPE material with a thickness of ≥ 1.5mm, and requires UV stabilization treatment, with a relatively high unit price.

4.2 Civilian projects (such as courtyard greening, parking lots)

Lightweight requirements: PP material (0.8-1.2mm thickness) is sufficient, and the surface can be treated without texture, resulting in a lower unit price.

5. Project Scale Affects the Geocell Price

Wholesale procurement: The larger the quantity, the lower the unit price.

Retail procurement: Small quantities (such as 1000 sqm) need to be priced according to retail, with small quantities and high losses, resulting in a 20% -50% increase in unit price.

6. Market Price Trends Affect the Geocell Price

6.1 Raw material fluctuations

Geocell's main raw materials (HDPE/PP) are petroleum derivatives, and as oil prices rise, the cost of polymers also increases. For example, in 2022, a 40% increase in international oil prices led to a rise in HDPE raw material prices from 8000 yuan/ton to 12000 yuan/ton, resulting in a 15% -20% increase in geocell production costs.

6.2 Regional market differences

Asian market: China, India and other countries have concentrated production capacity, and local brands (such as Shandong Tai'an manufacturer) have lower prices, but exporting to Europe and America requires an additional 20% -30% tariff.

7. Procurement Channels and Cost Optimization

7.1 Direct manufacturer procurement

Advantages: Transparent price (no middleman markup), customizable specifications (such as special welding distance), strong technical support.

Disadvantages: High minimum order quantity (usually starting from 5000 sqm), long delivery time (15-30 days).

7.2 Distributor Agent

Advantages: Small batch flexible procurement, fast spot supply (3-7 days), and localized services (such as installation guidance).

Disadvantage: Price increase of 10% -20%, and there may be outdated inventory.

Traditional supply chain: Obtaining stable prices through long-term cooperation, but with low flexibility.

Conclusion

Geocell, as an important material in modern engineering construction, are driving innovation in cost control through their price advantage. Domestic manufacturers such as BPM Geosynthetics(The Best Project Material Co.,Ltd) have successfully kept the price of HDPE geocells 20%-30% lower than imported brands through large-scale production and technological innovation, offering a more cost-effective option for various engineering projects. This geocell price advantage is not only reflected in the product itself but also throughout the entire supply chain, from production to transportation and installation. In the current context of expanded infrastructure investment but tight budgets, the high cost-effectiveness of domestically produced geocell makes them an ideal choice for large-scale engineering projects such as highways, railways, and water conservancy. Companies like BPM Geosynthetics have further strengthened this price advantage by optimizing production processes and providing localized services, enabling domestic engineering projects to obtain reliable geosynthetic solutions at more economical costs. In the future, with ongoing improvements in production processes and intensifying market competition, the price advantage of geocells is expected to become even more pronounced, creating greater value potential for the engineering construction industry.