Ultimate Guide To Geosynthetic Clay Liner Cost

Geosynthetic Clay Liner Cost: Comprehensive Guide for Industrial Buyers

Introduction

The Geosynthetic Clay Liner (GCL) has become a critical material in modern environmental and civil engineering projects. Known for its excellent impermeability and self-healing properties, it serves as an effective barrier for landfills, mining operations, and wastewater treatment facilities. However, when evaluating project budgets, understanding the Geosynthetic Clay Liner cost and its influencing factors becomes essential for engineers, procurement teams, and B2B buyers.

This article provides a comprehensive analysis of GCL pricing, technical specifications, market trends, and frequently asked buyer questions to support informed purchasing decisions.

Understanding Geosynthetic Clay Liners

What is a Geosynthetic Clay Liner?

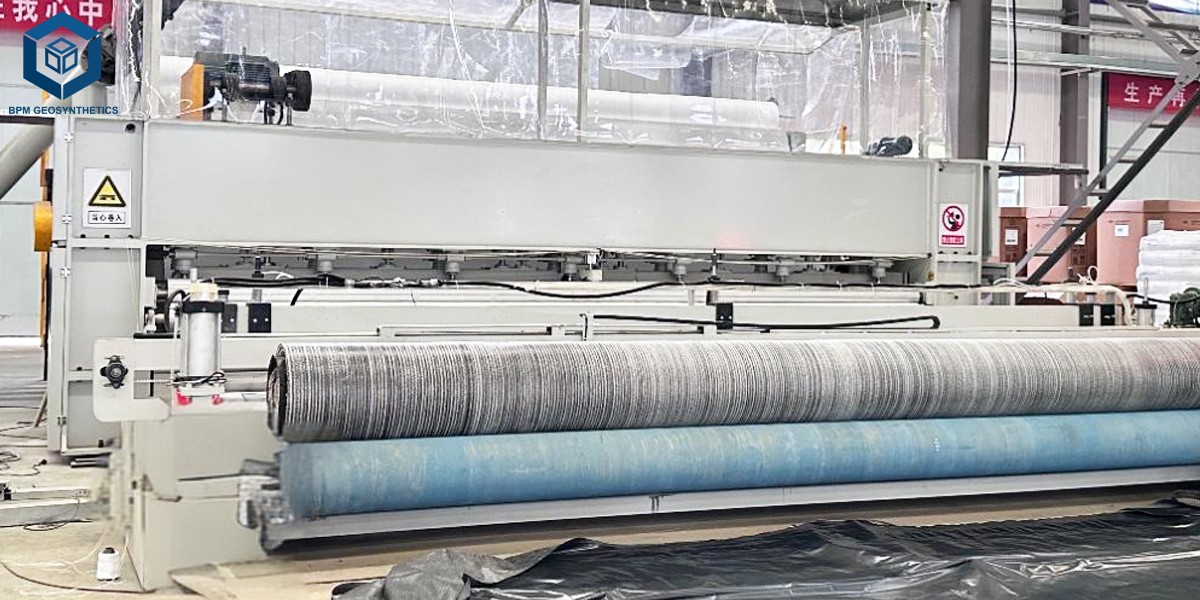

A Geosynthetic Clay Liner (GCL) is a composite geosynthetic material that consists of a layer of sodium bentonite clay encapsulated between two layers of geotextiles. The bentonite layer swells upon contact with water, forming a low-permeability barrier that effectively prevents liquid migration.

Key Advantages

Excellent impermeability: Permeability coefficient as low as 1×10⁻⁹ cm/s.

Self-healing capability: Automatically seals minor punctures and defects.

Chemical resistance: Stable against acids, alkalis, and other industrial contaminants.

Simple installation: Lighter and faster to deploy than traditional clay liners.

Durability: Proven long-term performance under a wide range of environmental conditions.

Factors Influencing Geosynthetic Clay Liner Cost

The cost of a Geosynthetic Clay Liner varies depending on several factors related to raw materials, specifications, and project conditions.

1. Material Composition and Bentonite Quality

Bentonite is the key functional component of a GCL. Premium-grade sodium bentonite offers better swelling capacity and lower permeability, but it also increases production costs. High-purity bentonite sourced from specific regions often commands a higher price due to superior mineral content.

2. GCL Structure and Weight

Different types of GCLs—such as needle-punched, adhesive-bonded, or reinforced GCLs—influence the overall cost. Heavier GCLs with higher bentonite content (typically 4–6 kg/m²) provide better sealing performance but come at a higher material cost.

3. Manufacturing Process and Quality Standards

The production process, including needle-punching density, thermal bonding, and quality control measures, impacts cost. Liners manufactured according to ASTM D5890, ISO 9001, or GRI-GCL3 standards ensure reliable performance but may cost slightly more due to testing and certification.

4. Project Size and Logistics

For large-scale projects, bulk purchasing and optimized logistics can significantly reduce unit costs. However, transportation distance and export conditions (such as moisture control and packaging) also influence pricing.

5. Market Region and Supply Chain

Global demand and raw material fluctuations affect the Geosynthetic Clay Liner price per square meter. Markets in North America, Europe, and Asia-Pacific often experience price variations based on import tariffs, shipping costs, and local availability of bentonite.

Average Geosynthetic Clay Liner Cost

While prices can vary based on specifications and regions, the average Geosynthetic Clay Liner cost typically ranges between USD 2.5 – 6.0 per square meter.

Standard GCL: USD 2.5 – 3.5/m²

Reinforced GCL: USD 3.8 – 5.0/m²

Premium or customized GCL: USD 5.0 – 6.0/m²

These figures are general estimates and may fluctuate depending on market conditions, freight charges, and project-specific requirements.

Applications of Geosynthetic Clay Liners

1. Landfill and Waste Containment

GCLs are widely used as base and capping liners in municipal and hazardous waste landfills. Their low permeability and self-healing capability ensure long-term environmental protection.

2. Mining and Heap Leach Pads

In mining operations, GCL liners prevent seepage of process solutions into the ground, offering a safe and economical containment system.

3. Wastewater Treatment and Reservoirs

GCLs are used in industrial wastewater ponds, reservoirs, and stormwater basins, providing cost-effective waterproofing solutions with minimal maintenance.

4. Tunnels and Underground Structures

For tunnels and below-grade construction, GCLs act as waterproof barriers that reduce hydrostatic pressure and protect structural integrity.

Market Insights and Trends

The global Geosynthetic Clay Liner market is projected to grow at a CAGR of over 6% from 2024 to 2030. Growth is primarily driven by increasing investments in environmental infrastructure, mining expansion, and stricter waste management regulations.

Sustainability has become a key focus, with many manufacturers introducing eco-friendly and recyclable GCLs that minimize carbon footprint while maintaining performance. The integration of GCLs with HDPE geomembranes is also a growing trend, offering enhanced dual-layer protection in critical containment applications.

FAQs About Geosynthetic Clay Liner Cost

1. What determines the cost of a Geosynthetic Clay Liner?

The main cost drivers include bentonite quality, liner thickness, manufacturing technology, and logistics. Project location and order volume can also influence the final price.

2. Is a GCL cheaper than an HDPE geomembrane?

While GCLs generally have a lower installation cost and faster deployment, HDPE geomembranes may offer longer service life in highly aggressive chemical environments. Many projects use a composite system of both materials for optimal performance.

3. How can I reduce Geosynthetic Clay Liner cost for large projects?

Buying in bulk, selecting regionally available materials, and optimizing transportation can reduce overall project costs. Working directly with experienced manufacturers ensures consistent quality at a competitive rate.

4. What is the expected lifespan of a GCL?

A properly installed GCL can last more than 30 years, depending on environmental conditions, soil pH, and exposure to UV light.

Conclusion and Call to Action

Understanding the Geosynthetic Clay Liner cost is essential for balancing performance, durability, and budget in modern infrastructure projects. From waste containment to mining and water resource management, GCLs offer a sustainable and reliable solution for long-term environmental protection.

We specialize in providing high-quality GCLs that meet international standards and project-specific needs. Our engineering team can assist with material selection, cost optimization, and installation guidance to ensure project success.

Contact us today for a detailed quotation or technical consultation on Geosynthetic Clay Liners tailored to your application.