What ls Geomembrane 200 Micron And lts Application?

Geomembrane 200 micron is a highly durable, versatile synthetic liner material that plays a crucial role in various civil engineering, environmental, and construction applications. With a thickness of 200 microns, these geomembranes are designed to provide impermeable barriers, making them ideal for preventing water seepage, controlling waste, and protecting the environment from contamination. This article will discuss the construction, application, standards, and advantages of 200-micron geomembranes, and how they are essential in modern engineering projects.

What is Geomembrane 200 Micron?

Geomembranes are synthetic materials used to prevent the movement of fluids or gases through a surface, ensuring impermeability. The 200-micron thickness refers to the material's thickness, typically made from high-density polyethylene (HDPE), polyvinyl chloride (PVC), or ethylene propylene diene monomer (EPDM). These materials are commonly used in a variety of industries to create barriers for water, chemicals, and other fluids.

Key Features of Geomembrane 200 Micron:

Thickness: 200 microns, providing a robust barrier without being too thick for easy handling and installation.

Durability: Resists physical damage, UV degradation, and environmental stress.

Waterproofing: Effective at preventing water and moisture from passing through.

Flexibility: Can conform to various shapes and surfaces, allowing for easier installation.

Engineering Principles Behind Geomembrane 200 Micron

Impermeability:

The primary purpose of a geomembrane is to create a barrier that prevents water or fluid leakage. Geomembrane 200 micron offers effective protection by using a compact, robust structure that is difficult to puncture or degrade.Chemical Resistance:

High-quality geomembranes are resistant to a wide range of chemicals and industrial fluids, ensuring long-lasting performance even in harsh environments.UV Resistance:

Geomembranes are designed to withstand prolonged exposure to ultraviolet (UV) radiation, a critical factor for outdoor applications like landfills or water containment.Tensile Strength:

The material is engineered to withstand significant mechanical stresses, making it suitable for use in projects where large forces are applied, such as construction sites or large-scale containment areas.

Applications of Geomembrane 200 Micron

Geomembrane 200-micron liners are widely used in numerous sectors where water containment and fluid management are critical. Below are some key applications:

Landfills:

Geomembranes are used as liners in landfills to prevent the leakage of hazardous materials into the surrounding soil and groundwater. The 200-micron geomembrane provides a strong barrier against leachates and other contaminants.Water Reservoirs and Dams:

These geomembranes act as liners for water containment systems, ensuring that water does not seep through the dam structure, maintaining water levels for irrigation, industrial use, or hydroelectric generation.Wastewater Treatment Plants:

Geomembrane liners help in controlling the containment of wastewater, preventing seepage into the environment. They are used in channels, ponds, and lagoons to handle wastewater without leakage.Mining Operations:

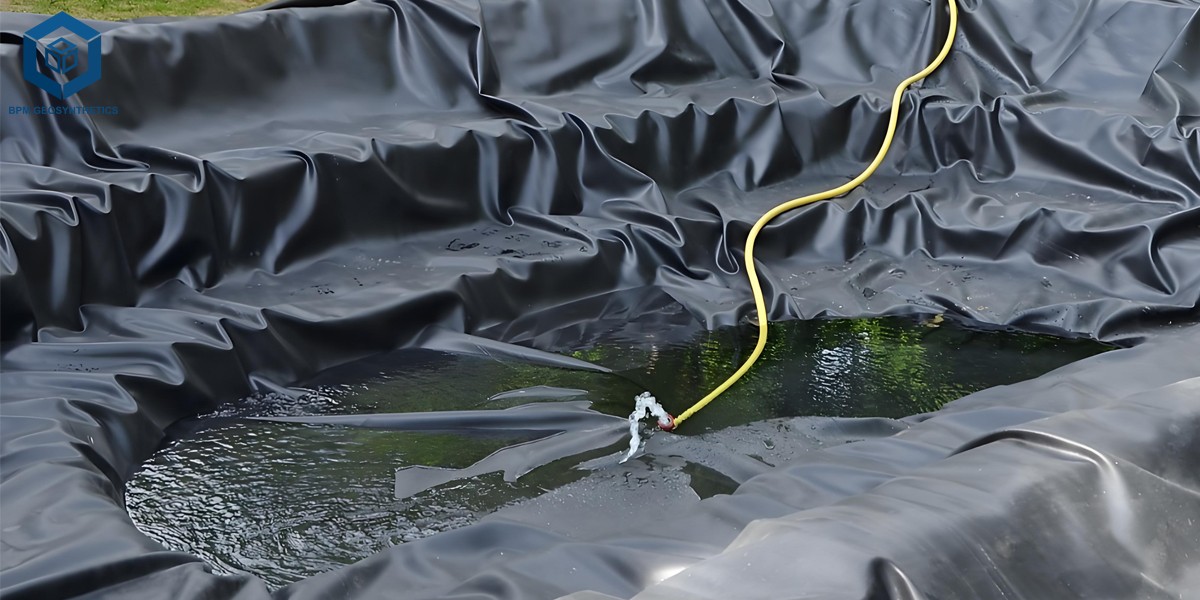

Geomembranes are applied in mining operations to prevent contamination of the surrounding land and water sources. They are used for tailings storage and as liners for heap leaching pads, protecting the environment from toxic runoff.Agricultural Ponds:

Geomembranes are often used for creating water storage ponds in agricultural projects, ensuring that water stays contained for irrigation purposes without being absorbed into the ground.

Industry Standards and Regulations

Geomembranes, including 200-micron liners, must meet specific international standards to ensure their performance and safety in various applications:

ASTM D6747: Standard specification for geomembranes used in waste containment and water management.

ISO 9001: Quality management system for manufacturers to maintain consistent product standards.

ISO 13434: International standard for testing the performance of geomembranes in environmental applications.

EPA Regulations: Geomembranes used in environmental projects must comply with the Environmental Protection Agency (EPA) standards for waste containment and water protection.

Installation Considerations

Surface Preparation:

Proper surface preparation is crucial to ensure the geomembrane adheres effectively to the substrate. The surface should be cleaned, smooth, and free of sharp objects that might damage the liner during installation.Seam Welding:

Geomembrane seams should be welded using specialized heat fusion techniques to create an impermeable bond. This ensures that no water or contaminants can pass through the seams.Testing for Integrity:

After installation, the geomembrane should be tested for leaks using methods like electrical leak location (ELL) to detect potential faults in the material.Protection:

A layer of geotextile or gravel may be used to protect the geomembrane from punctures or physical damage after installation, especially in high-traffic areas or places prone to sharp objects.

Frequently Asked Questions (FAQ)

Q1: Is a 200-micron geomembrane suitable for all applications?

No, while a 200-micron geomembrane offers strong waterproofing, it may not be suitable for applications with high mechanical stress or chemical exposure. In such cases, a thicker or more chemically resistant geomembrane may be necessary.

Q2: How long does a geomembrane last?

When properly installed and maintained, a geomembrane can last up to 50 years or more, offering long-term protection.

Q3: Can geomembranes be recycled?

Yes, geomembranes, particularly those made from HDPE, are recyclable and can be reused in future applications, making them an eco-friendly solution for construction projects.

Q4: How do geomembranes help with water conservation?

By preventing water leakage, geomembranes ensure that reservoirs, dams, and agricultural ponds retain their water, reducing waste and improving water conservation efforts.

Conclusion: Why Choose Geomembrane 200 Micron?

Geomembrane 200 micron is a reliable, cost-effective solution for water and fluid containment across various industries. With its high resistance to UV radiation, chemical exposure, and mechanical stress, it provides a durable and long-lasting barrier for landfills, water reservoirs, wastewater treatment plants, and more. Adhering to ASTM, ISO, and EPA standards ensures the material’s quality and safety. For optimal performance, proper installation and regular maintenance are crucial.