What is Geo Membrane for Gold Mining?

Gold mining is a complicated and resource-intensive enterprise that requires environment friendly and environmentally accountable options to manipulate waste, forestall contamination, and optimize healing processes. One of the most crucial elements in current gold mining operations is the geo membrane—a high-performance artificial liner used for containment, seepage control, and environmental protection.This article will discover the function of geo membranes in gold mining, including:Why geo membrane is appropriate for gold mining.The advantages of geo membrane for gold mining operations.Key traits of geo membrane in gold mining projects.

1. What is Geo Membrane for Gold Mining?

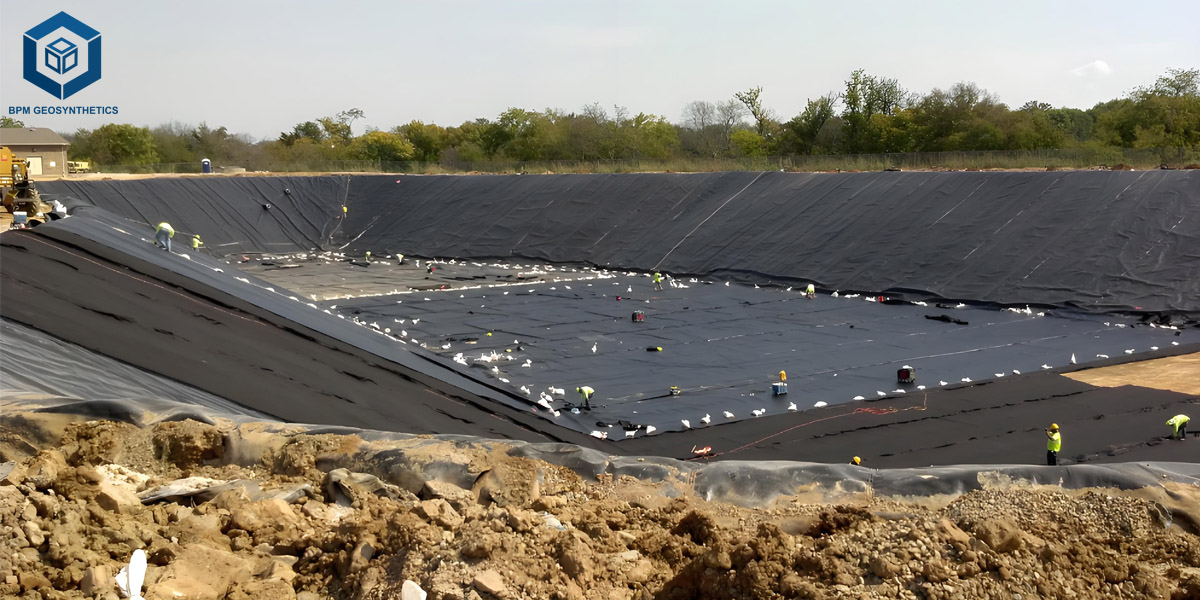

A geo membrane liner is regarded as a synthetic barrier, main purpose being the prevention of leaks and the stoppage of hazardous chemicals escape, usually made of high-density polyethylene (HDPE) or similar resistant polymers. When mining operations have to be contained, these liners, which are their combination of flexibility, chemical resistance, and tensile strength, are able to withstand the mining plus mechanical stresses which are found commonly in gold mining sites -so they are used for this purpose.

Geomembrane sheet is basically the pond liners for tailings ponds, evaporation ponds, heap leach pads, and chemical containment areas. They are the ones that prevent toxic or corrosive substances from soil or groundwater.

To give an instance, in gold mining, leach pads that utilize impermeable geomembrane is capable of confining the use of cyanide or other chemicals in the extraction of gold from ore. As a result, the environment is not contaminated, and the extraction process becomes efficient since the chemicals are concentrated in the pad instead of surrounding soil. The use of hdpe membrane in mining operations due to their reliability, durability, and installation ease has thus been the key to the mining companies' compliance with environmental regulations and operational efficiency.

2. Why are Suitable Geo membrane for Gold Mining?

Gold mining is a resource-intensive enterprise that generates enormous volumes of liquid and stable waste, a lot of which can be hazardous to the environment. The three core waste administration challenges in gold mining include:

- Heap Leaching – A procedure in which cyanide or acidic solutions are sprayed or dripped onto stacked ore to extract gold. The manner requires strict containment to forestall chemical seepage.

- Tailings Storage – Large volumes of leftover ore slurry have to be saved safely, regularly for decades, besides leakage into the surrounding environment.

- Process Water Containment – Mining operations count number on massive quantities of water, which can turn out to be contaminated and have to be remoted from soil and groundwater.

To mitigate environmental chance and enhance operational performance, geomembranes serve as a critical impermeable barrier throughout all these applications. They assist comprise unsafe fluids, forestall floor infiltration, and guide regulatory compliance.

2.1 Geo Membrane Chemical Resistance

Gold extraction regularly includes highly corrosive and poisonous chemicals, including:

- Cyanide – used in heap leaching to dissolve gold from ore.

- Sulfuric Acid – used in oxidized ore or copper-gold processes.

- Heavy Metals and Reagents – which can pose long-term environmental hazards.

HDPE (High-Density Polyethylene) and LLDPE (Linear Low-Density Polyethylene) geomembranes are noticeably resistant to these substances. Their molecular shape provides:

- Exceptional chemical stability, even beneath non-stop exposure.

- No danger of softening, swelling, or cracking triggered by way of acids or solvents.

- Long carrier life except fabric breakdown or leakage risk.

This makes them best for lining leach pads, answer ponds, and chemical storage areas, the place chemical resistance is non-negotiable.

2.2 Geo Membrane Durability and Longevity

Mining environments are extraordinarily harsh and pose numerous bodily and climatic challenges:

- Mechanical damage – triggered through tough terrain, sharp stones, and heavy equipment.

- UV radiation – in particular in high-altitude or open-pit sites, which can hastily degrade unprotected materials.

- Temperature extremes – with severe warmth all through the day and freezing temperatures at night time or throughout iciness seasons.

Geo membrane is engineered to operate underneath such stipulations with the aid of offering:

- High puncture and tensile strength, stopping tears from sharp ore or base layers.

- Outstanding UV resistance, in particular in HDPE geomembrane handled with carbon black for long-term daylight exposure.

- Low-temperature flexibility, making sure that the liner stays elastic and intact even in sub-zero conditions.

As a result, true established geomembrane can characteristic reliably for 20 to 30 years or more, even in uncovered conditions.

2.3 Geo Membrane Environmental Compliance

Governments and regulatory our bodies global impose strict requirements on mine waste dealing with due to the chance of long-term environmental damage. Common guidelines include:

- ISO 14001 environmental administration systems

- EPA containment and groundwater safety rules

- Local mining codes and hazardous waste guidelines

Geomembranes play a fundamental function in assisting mining companies:

- Prevent poisonous chemical seepage into groundwater and close by ecosystems.

- Control floor runoff from leach pads or tailings dams.

- Demonstrate compliance throughout environmental inspections and audits.

Using geomembrane no longer solely ensures criminal compliance however additionally reduces threat exposure, defending the company’s social license to function and its reputation.

2.4 Cost-Effectiveness

Although geomembrane contain upfront fabric and set up costs, they supply massive long-term financial savings in contrast to regular lining structures such as compacted clay or concrete.

Key price blessings include:

- Faster installation – Geomembrane sheets are faster to deploy, weld, and look into than setting up multi-layer clay liners.

- Lower protection needs – Unlike clay liners that can crack or erode, geomembranes require minimal upkeep as soon as installed.

- Improved operational efficiency – Geomembrane forestall water loss throughout heap leaching, keeping optimal answer circulation and growing gold restoration rates.

- Reduced environmental remediation costs – By warding off leaks and infection events, mining operations can keep away from high priced cleanup or criminal penalties.

When evaluated over the full lifecycle of a mining project, geomembrane persistently supply better overall performance at a decrease complete cost.

3. Effects of Geo Membrane for Gold Mining

The utility of geo membrane in current gold mining has dramatically accelerated the industry's efficiency, environmental responsibility, and economic viability. These engineered liners have emerge as an integral element of protected and sustainable mine web site operations. Below are the key influences and advantages of the use of geo membrane in gold mining:

3.1 Geo Membrane - Enhanced Gold Recovery (Heap Leaching Efficiency)

Heap leaching is a broadly used approach in gold extraction, in particular for low-grade ores. It includes stacking overwhelmed ore on a leach pad and making use of cyanide or acidic options to dissolve gold particles.

Without an high quality geomembrane liner, the procedure suffers from widespread losses and environmental risks:

- Up to 30% of the leaching solution might also seep into the ground, lowering the quantity of gold recovered.

- Hazardous chemical leakage can contaminate soil and groundwater, requiring steeply-priced environmental remediation.

With the set up of HDPE or LLDPE geomembranes, mining operations gain from:

- Complete containment of leaching solutions, making sure that fluids continue to be inside the manner area.

- Improved gold healing rates, considering that extra answer is reachable to extract gold from ore.

- Reduced chemical use, as much less answer is lost—leading to decrease reagent costs.

- Improved leach pad performance, making sure structural steadiness and longer carrier life.

These advantages at once translate into higher yield, lower operational costs, and better return on investment for mining companies.

3.2. Geo Membrane - Safer Tailings Management

Tailings are the fine-grained waste substances left after ore processing. They frequently comprise toxic substances such as arsenic, mercury, and residual cyanide, posing serious environmental and fitness risks if now not correct contained.

Unlined or poorly lined tailings storage services (TSFs) are prone to:

- Seepage of contaminants into close by soil and aquifers

- Structural instability, growing the hazard of dam collapse

- Long-term liability, as tailings can continue to be hazardous for decades

Geomembranes play a crucial position in tailings administration by:

- Creating a watertight barrier between tailings and the herbal ground

- Reducing the hazard of catastrophic failure, such as the 2019 Brumadinho dam catastrophe in Brazil

- Ensuring compliance with global security requirements and environmental laws

- Facilitating long-term monitoring and closure planning of the TSF

Overall, geomembranes decorate the safety, stability, and regulatory compliance of tailings impoundments.

3.3. Geo Membrane - Water Conservation & Recycling

Water is a necessary useful resource in gold mining, used in ore processing, dirt control, and tailings transport. In many mining regions—especially arid or faraway areas—water scarcity poses a indispensable operational challenge.

Geomembranes help efficient water use through:

- Capturing and containing system water, permitting for on-site cure and reuse

- Preventing seepage and evaporation, which are foremost reasons of water loss

- Minimizing the want for freshwater intake, lowering the environmental footprint

- Supporting zero-discharge operations, aligned with contemporary sustainability goals

By recycling and conserving water, geomembranes now not solely decrease operational expenses however additionally assist businesses meet **ESG (Environmental, Social, Governance) expectations from regulators and investors.

3.4. Geo Membrane - Reduced Remediation Costs

Mining operations that forget appropriate containment frequently face main environmental cleanup costs years—even decades—after website online closure. These unplanned prices can harm a company's price range and reputation.

Geomembranes assist keep away from such long-term liabilities by:

- Prolonging the life of vital containment structures like leach pads, ponds, and tailings dams

- Reducing the threat of contamination, which would in any other case require large remediation

- Lowering post-closure rehabilitation costs, such as soil replacement, groundwater treatment, or web site regrading

- Protecting company image, with the aid of demonstrating proactive environmental administration and decreasing the probability of accidents or public backlash

By investing in geomembranes upfront, mining organizations can control environmental risks, optimize long-term costs, and hold a positive manufacturer reputation at some stage in the mine lifecycle.

4. Characteristics of Geo Membrane for Gold Mining

Not all geomembranes are equal—gold mining requires specific material properties for optimal performance.

4.1 Geo Membrane for Gold Mining Material Types

Type | Best For | Advantages |

HDPE | Heap leach pads, tailings dams | High chemical resistance, durable, cost-effective |

LLDPE | Flexible liners, exposed areas | More puncture-resistant, better elongation |

PVC | Temporary liners, secondary containment | Easier installation, good flexibility |

4.2. Geo Membrane Thickness & Strength

In mining applications, geo membrane have to withstand a range of mechanical and geological forces. Choosing the splendid thickness and energy traits is quintessential to overall performance and safety.

- Typical Thickness Range: 1.5 mm to three mm

These thicknesses are generally used for leach pads, tailings dams, and answer ponds. Thicker liners grant elevated mechanical sturdiness and puncture resistance.

- High Tensile Strength

Geo membrane used in mining have to stand up to stress brought on with the aid of settling subgrades, seismic movement, or stacked ore loads. High-density polyethylene (HDPE) liners are regarded for their excellent tensile properties, making sure dimensional balance over time.

- Exceptional Puncture and Tear Resistance

Mining web sites are regularly protected with sharp rocks, gravel, and beaten ore. A long lasting geo membrane need to be capable to face up to punctures in the course of and after set up to avoid breaches that ought to lead to environmental contamination.

Selecting the proper thickness and mechanical electricity helps make certain the integrity and long-term performance of containment structures in even the most annoying mining conditions.

4.3. Geo Membrane Seaming & Installation

Proper set up is simply as vital as cloth quality. Even the fine geo membrane can fail if seams are now not securely bonded or if liner stress is now not exact managed.

- Thermal Fusion Welding

High-quality seams are completed via hot wedge welding or extrusion welding, which fuses two liner sheets into a homogeneous, leak-proof bond. This system is desired over adhesives or mechanical joins due to its superior energy and durability.

- Rigorous Quality Control Testing

To warranty seam integrity, checking out strategies such as spark testing, air stress testing, and vacuum testing are employed for the duration of and after installation. These processes observe any vulnerable factors or leaks earlier than the gadget is positioned into operation.

- Proper Slope and Subgrade Preparation

Leach pads and tailings ponds ought to be designed with engineered slopes to limit hydrostatic strain and stop slippage. A smooth, compacted subgrade protects the liner from useless stress and deformation.

Through expert set up practices and stringent nice assurance protocols, mining operators can extensively limit the danger of liner failure or expensive repairs.

4.4 Geo Membrane UV & Oxidation Resistance

Exposure to daylight and oxygen can degrade polymer substances over time, main to brittleness and cracking. In open-pit gold mining, the place liners are regularly exposed to the elements, UV and oxidation resistance are critical.

- Carbon Black Stabilization

High-quality HDPE geo membrane include carbon black, a effective UV stabilizer that protects the liner from the unsafe results of sunlight. This permits uncovered liners to function reliably for 20 years or more.

- Antioxidant Additives

Geo membrane is formulated with antioxidants and warmth stabilizers that sluggish the charge of oxidative degradation. These components prolong the liner’s lifespan, specifically in high-temperature or chemically reactive environments.

- Resistance to Environmental Stress Cracking (ESC)

A principal reason of untimely failure, ESC is mitigated thru material formula and manufacturing controls, making sure long-term sturdiness even beneath stress.

Combined, these points permit geo membrane to feature efficaciously in out of doors mining applications, withstanding UV exposure, chemical attack, and mechanical wear for decades.

4.5 The Service Life of HDPE Geo membrane in Gold Mining

Geo membrane is a long-term funding in environmental safety and operational performance. When desirable designated and installed, HDPE liners provide a service existence of 20–50 years, relying on:

- Exposure conditions (covered vs. uncovered installations)

- Chemical and thermal load

- Quality of substances and welds

- Maintenance and monitoring protocols

4.5 Geo Membrane Key Advantages Over Time:

- Long-Term Containment

HDPE geo membrane preserve their impermeability and energy over decades, making sure dependable separation of hazardous waste from the environment.

- Reduced Remediation Costs

By stopping leakage and contamination, geo membrane minimize the want for pricey cleanup operations after mine closure.

- Support for Mine Closure and Rehabilitation

A well-installed geo membrane device makes last website online reclamation greater predictable and compliant with environmental standards.

5. Conclusion: Geo Membrane is Essential for Gold Mining

Geo membrane play a critical position in contemporary gold mining via offering dependable containment, defending water resources, and bettering gold recovery. As environmental policies tighten, superior options like strengthened liners and leak detection structures have end up necessary for secure and sustainable operations.

BPM Geosynthetics presents extraordinary geo membrane merchandise designed specially for mining needs. With a sturdy tune document and technical expertise, BPM helps mining groups minimize risks, decrease costs, and meet environmental standards.

Choose BPM Geosynthetics — your dependable companion for accountable gold mining.