How to Choose Right GCL Geosynthetic Clay Liner?

GCL Geosynthetic Clay Liner is essential to modern-day engineering. Its herbal bentonite swells with water to structure a dense anti-seepage layer. It is environmentally friendly, non-toxic and has awesome anti-seepage performance. It can successfully block liquid and fuel leakage and guard groundwater and soil safety. Choosing the proper water-proof blanket has far-reaching significance: first, it ensures the anti-seepage impact of the task and avoids leakage accidents brought about through inadequate fabric performance; second, it improves development efficiency. Its mild and effortless to lay and sturdy self-healing residences can shorten the building length and decrease costs; third, it ensures the long-term steadiness of the project. Its anti-aging and anti-corrosion homes prolong its carrier life; fourth, it complies with environmental safety legal guidelines and regulations, helps inexperienced engineering construction, avoids prison risks, and lays the basis for the project's safety, economy, and sustainable development.

1. Introduction

1.1 Brief overview of GCL geosynthetic clay liner and its significance in a number of projects

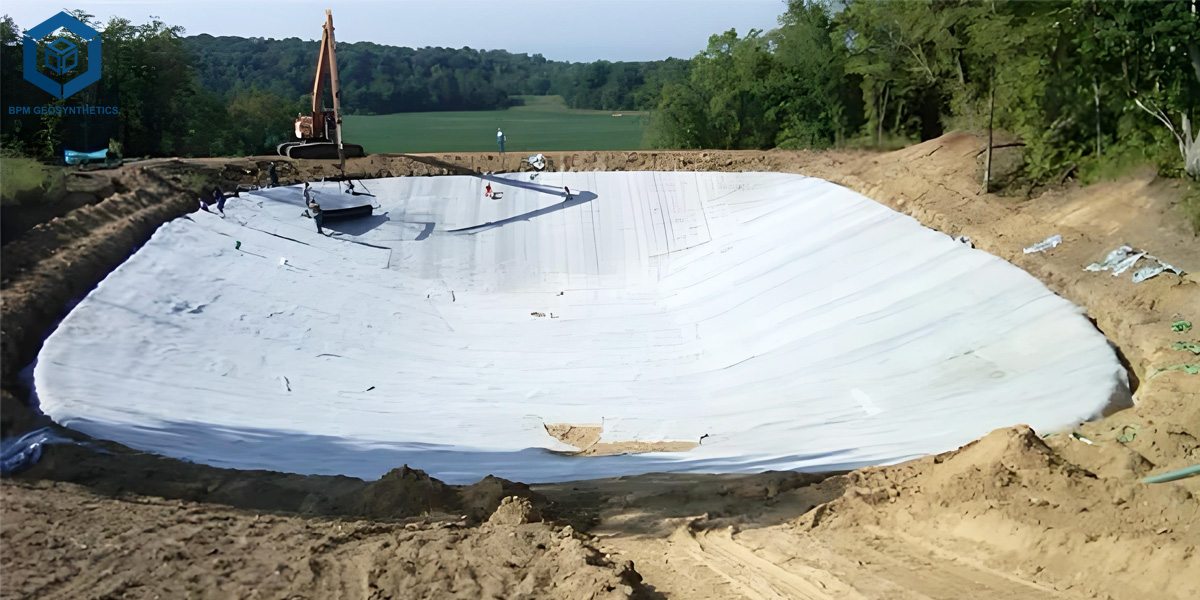

GCL (geosynthetic clay liner) is a geocomposite liner with bentonite sandwiched between geotextiles. It presents optimal seepage control, eco-friendliness, and adaptability, quintessential for landfills, dams, and environmental projects.

1.2 Purpose of the article: guide on deciding on the proper GCL Geosynthetic Clay Liner

This article gives sensible coaching on deciding on the proper GCL liner, protecting key elements like performance, compatibility, and price for challenge success.

2. Understanding GCL Geosynthetic Clay Liner Basics

2.1 Composition of GCL Geosynthetic Clay Liner

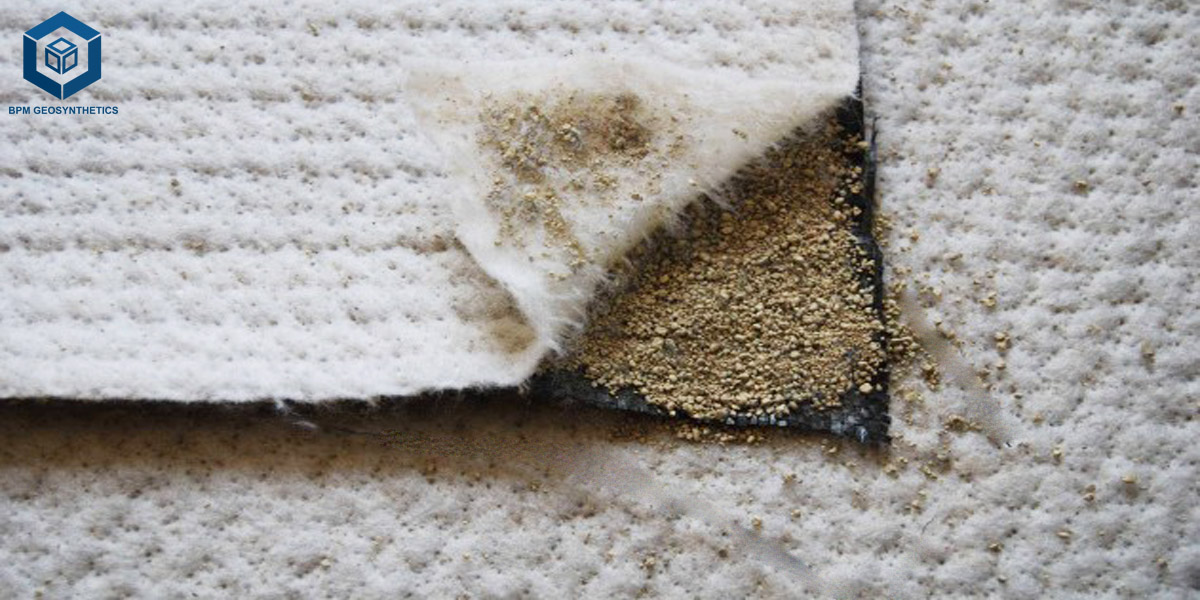

GCL Clay Liner is typically composed of geotextile, bentonite granular layer and protecting layer (such as woven material or anti-seepage membrane). According to the process, it can be divided into three categories: needle punching technique (GCL-NP), needle punching movie approach (GCL-OF) and adhesive approach (GCL-AH). Its core fabric is herbal sodium-based bentonite, which has the traits of swelling with water to shape a dense water resistant layer, and the permeability coefficient is as low as 5×10⁻¹¹ cm/s, which can successfully block liquid and gasoline leakage.

2.2 Role of every factor in the overall performance of GCL Geosynthetic Clay Liner

The overall performance of GCL Bentonite (Geosynthetic Clay Liner) is mutually decided by means of its core components: geotextile offers structural guide and tensile strength, bentonite granular layer realizes the core feature of waterproofing and anti-seepage, and shielding layer (such as woven material or anti-seepage membrane) enhances sturdiness and building adaptability. The unique features of every element are as follows:

2.2.1 Geotextile: As the skeleton of GCL, geotextile (usually non-woven material or woven fabric) is tightly mixed with bentonite particles through a needle punching process. Its excessive tensile energy and elongation grant structural assist for GCL Pond Liner to stop tearing or deformation prompted with the aid of exterior forces all through development or use. At the equal time, the tough floor of the geotextile will increase the friction coefficient, which is conducive to the steady mixture of GCL and the base or different materials.

2.2.2 Bentonite granular layer: This is the core of GCL waterproofing and anti-seepage. Natural sodium-based bentonite swells greater than 24 instances when it comes into contact with water, forming a uniform colloid system, filling the house of geotextile fibers and blocking off the water penetration path. Its permeability coefficient is as low as 5×10⁻¹¹ cm/s, which is equal to a hundred instances the density of 30cm thick clay, and it has self-healing residences - when it is in part damaged, the bentonite expands to mechanically restore the cracks.

2.2.3 Protective layer (such as woven fabric or anti-seepage membrane): In the needle-punched movie technique (GCL-OF) or adhesive technique (GCL-AH), the protecting layer (such as HDPE geomembrane) covers the outdoor of the bentonite layer to beautify the sturdiness and puncture resistance of the GCL Geosynthetic Clay Liners. It prevents the bentonite from absorbing water and swelling prematurely, and protects the core water-resistant layer from bodily or chemical injury all through building and long-term use.

3. How to Choose Right GCL Geosynthetic Clay Liner?

Choosing a appropriate bentonite water-resistant blanket (Geo Synthetic Clay Liner) requires complete consideration of six core dimensions: material, performance, specifications, appearance, producer skills and engineering adaptability. The particular factors are as follows:

3.1 GCL Geosynthetic Clay Liner Material: Natural sodium-based bentonite as the core

- Purity of ingredients: It need to be herbal sodium-based bentonite, and ought to now not incorporate impurities or artificially modified substances to make sure water enlargement charge (≥24ml/2g) and long-term stability.

- Filling form: Geocomposite Clay Liner crammed with powdered bentonite is desired due to the fact it expands greater evenly and has higher anti-seepage impact than granular ones; tasks with excessive anti-seepage necessities (such as landfills) ought to keep away from the use of granular products.

- Structural process: Bentonite Geosynthetic Clay Liner constant via needle puncture has greater shear strength, and the fiber and bentonite are tightly blended to stop bentonite loss at some point of building or use.

3.2 GCL Geosynthetic Clay Liner Performance: Meet enterprise requirements and engineering requirements

- Anti-seepage performance: The water permeability coefficient ought to be ≤5×10⁻¹¹ cm/s (ASTM D5084 standard), which is equal to one hundred instances the density of 30cm thick clay.

Hydrostatic stress resistance ≥ 0.4MPa (no leakage for 1 hour), high-demand initiatives (such as reservoirs) require ≥ 0.6MPa.

- Physical stability: Tensile power ≥ 600N/100mm (JG/T 193-2006 standard) to make sure building resistance to pulling.

Peel power (non-woven fabric and woven fabrics) ≥ 40N/100mm to stop interlayer separation.

- Chemical stability: Acid and alkali resistant, sewage corrosion resistant, appropriate for chemical storage tanks and different scenes.

Durability: Bentonite sturdiness index (2g sample) ≥ 20ml/2g, making sure long-term use except failure.

3.3 GCL Geosynthetic Clay Liner Specifications: Matching challenge dimension and building conditions

- Unit location mass: Common specs are 4000-6000g/㎡, pick in accordance to the anti-seepage level:

4000-4500g/㎡: Suitable for established underground tasks (such as basements).

5000-6000g/㎡: used in high-demand eventualities (such as landfill lining).

- Width and length: popular width ≥4.5m (such as 6m×30m), limit lap joints; size is custom-made in accordance to challenge necessities (such as 20m, 25m).

- Thickness: ≥5mm, to make sure that the bentonite layer is entirely improved to structure a dense water-proof layer.

3.4 GCL Geosynthetic Clay Liner Appearance: No defects to make sure development quality

- Connection parts: The lap joints have to be flat and free of defects to keep away from leakage risks.

- Blanket surface: no wrinkles, folds, holes or tears, uniform colour and no impurities.

- Edge treatment: neat edges, no harm or free fibers.

3.5 GCL Geosynthetic Clay Liner Manufacturer qualifications: to make certain product exceptional and after-sales

- Test report: It is required to furnish a take a look at record from a country wide accreditation business enterprise (such as CMA) to affirm overall performance indicators.

- Project cases: provide precedence to producers with trip in large-scale tasks such as landfills and reservoirs, and instances can confirm the proper impact of the product.

- Service support: together with development guidance, logistics assist and after-sales renovation to minimize engineering risks.

3.6. GCL Geosynthetic Clay Liner Engineering adaptability: Personalized choice in accordance to the scene

- GCL Geosynthetic Clay Liner for Slope engineering: when the slope is higher than 10%, minimize the wide variety of overlaps alongside the slope length, and the Geosynthetic Liner on the slope desires to exceed the slope foot line by means of greater than 1.5m.

- GCL Geosynthetic Clay Liner for Cold areas: pick out cold-resistant GCL to make sure that it can nevertheless be developed in an surroundings of -20℃ and will now not wreck brittlely.

- GCL Geosynthetic Clay Liner for Composite use: when used in conjunction with HDPE geomembrane, GCL ought to have puncture resistance to forestall leakage below the membrane.

4. Conclusion

The key to selecting the proper GCL geosynthetic bentonite liner is to consider: bentonite kind (sodium-based is preferred), mass per unit place (the greater the waterproofing, the better), geotextile best (affects sturdiness and shear strength); chemical compatibility have to additionally be viewed to make sure no destructive reactions with contact substances; building conditions, such as base remedy and laying methods, need to additionally be considered; and finally, cost-effectiveness need to be taken into account to stability material, development and renovation costs.

If you are searching for a dependable and low-cost answer for seepage control, BPM Geosynthetics Geosynthetic Clay Liner (GCL) is your excellent choice. Contact us nowadays to analyze greater about our exceptional bentonite liner for your project.