What is 8 Oz Non Woven Geotextile Fabric?

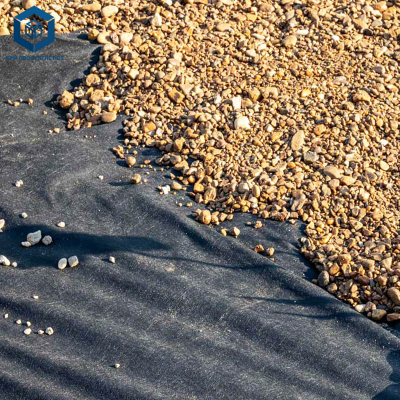

8 oz Non Woven Geotextile Fabric is a premium-grade geosynthetic fabric designed for strength, durability, and versatility in civil engineering, landscaping, and building projects. Weighing 8 oz. per rectangular yard (approximately 226 gsm), this heavy-duty non-woven cloth affords tremendous filtration, separation, and safety features whilst permitting water to skip thru freely. Manufactured from brilliant polypropylene or polyester fibers the use of superior bonding or needle-punching technology, it promises greatest overall performance in drainage, soil stabilization, and erosion control. Whether you are constructing roads, defending slopes, or putting in drainage systems, 8 oz non woven geotextile material ensures long-lasting consequences and cost-efficient challenge performance.

1. What Are the Main Applications of 8 Oz Non Woven Geotextile Fabric ?

1.1 8 Oz Non Woven Geotextile Fabric for Filtration

8 oz non woven geotextile lets in water to ignore via whilst correctly preserving soil particles, stopping the loss of precious soil and fending off clogging in drainage systems. Commonly used in French drains, subsurface drainage, and erosion manage structures, it ensures long-term water float effectivity whilst keeping soil stability.

1.2 8 Oz Non Woven Geotextile Fabric for Separation

Geotextile Fabric 8 oz acts as a barrier between layers of soil, sand, and combination substances with extraordinary particle sizes, stopping them from mixing over time. This separation is crucial for roadbeds, railway foundations, and constructing pads to keep electricity and stability.

1.3 8 Oz Non Woven Geotextile Fabric for Reinforcement

By including tensile energy to the soil, this geotextile helps stabilize susceptible or free ground, enhancing its load-bearing capacity. This is in particular recommended in building over smooth soils, lowering the threat of contract and structural deformation.

1.4 8 Oz Non Woven Geotextile Fabric for Erosion Control

Ideal for stopping soil loss on slopes, embankments, and shorelines, the 8 oz Needle Punch Filter Fabric holds soil in region even underneath heavy rain or water flow. It is extensively used in slope stabilization projects, riverbank protection, and coastal protection works.

1.5 8 Oz Non Woven Geotextile Fabric for Road and Pavement Construction

When positioned beneath roads or pavements, the material helps distribute hundreds evenly and prevents soil and combination intermixing. This will increase pavement life, reduces protection costs, and improves long-term performance.

1.6 8 Oz Non Woven Geotextile Fabric for Landfill and Waste Containment

Used as phase of landfill liner and covers, it prevents the motion of contaminants whilst supplying structural help to the waste containment system. Non Woven Geotextile Fabric 8 oz additionally improves the effectivity of leachate series systems.

1.7 8 Oz Non Woven Geotextile Fabric for Agriculture

In farming and landscaping, geotextile fabric is utilized for weed suppression, soil moisture retention, and stabilization of agricultural pathways. It helps more healthy crop increase and reduces upkeep efforts.

2. How Does the Overall Performance and Sturdiness of 8 Oz Non Woven Geotextile Fabric Compare to Other Geotextile Weights and Materials?

The overall performance and sturdiness of geotextile fabric rely on quite a number factors, consisting of weight, cloth composition, and precise software requirements. While the weight of geotextile cloth is one factor to consider, it is now not the sole determinant of performance. Here's a prevalent contrast between 8 oz nonwoven geotextile material and different geotextile weights/materials:

2.1 Geotextile Fabric Performance:

- Filtration: Geotextiles with greater weights usually grant higher filtration effectivity by means of stopping soil particles from passing via the fabric. Heavier geotextiles can have greater permittivity and permit for increased water go with the flow rates.

- Separation: Geotextiles with greater weights provide increased separation capabilities, mainly for functions involving heavy masses or coarse-grained soils.

- Reinforcement: Heavier geotextiles generally supply greater tensile power and higher load-bearing capacity, making them extra appropriate for reinforcement applications.

- Erosion Control: Both lighter and heavier geotextiles can be fine in erosion control, relying on the unique assignment necessities and soil conditions.

2.2 Geotextile Fabric Durability:

- Material Composition: The sturdiness of geotextile material is influenced with the aid of the fabric used. Polypropylene and polyester are frequent materials, with polypropylene exhibiting suitable resistance to organic degradation, chemicals, and UV exposure. Polyester is recognised for its excessive power and resistance to elongation.

- Installation Conditions: Proper set up techniques, such as enough anchoring and safety from development damage, play a tremendous position in the long-term sturdiness of geotextiles.

- Environmental Factors: The sturdiness of Non Woven geotextile can be affected by using publicity to chemicals, temperature fluctuations, moisture, and organic elements current in the task environment.

3. Why Pick Out 8 Oz Non Woven Geotextile Fabric for Drainage?

Choosing 8 oz Geotextile Fabric for drainage structures gives quite a few advantages:

3.1 8 Oz Non Woven Geotextile Fabric - Filtration Efficiency

The 8 oz weight of the nonwoven geotextile presents a stability between filtration effectivity and permeability. It approves for sufficient water float whilst efficaciously filtering out first-rate soil particles. This helps forestall clogging and keeps the long-term overall performance of the drainage system.

3.2 8 Oz Non Woven Geotextile Fabric - Cost-Effectiveness

8 oz Geotextile is usually greater reasonably-priced in contrast to heavier weights. They grant dependable filtration and separation features at a decrease cost, making them a sensible preference for many drainage applications. The fee financial savings can be significant, specifically in large-scale projects.

3.3 8 Oz Non Woven Geotextile Fabric - Versatility

Non Woven Geotextile Fabric is versatile and appropriate for a extensive vary of drainage applications. They can be used in a number of soil sorts and task conditions, presenting dependable filtration and separation skills in exceptional environments.

3.4 8 Oz Non Woven Geotextile Fabric - Ease of Installation

The lighter weight of geotextile drainage fabric makes them exceptionally less complicated to manage and installation in contrast to heavier geotextile fabric. This can end result in time and labor financial savings at some point of the set up process.

3.5 8 Oz Non Woven Geotextile Fabric - Environmental Compatibility

Non Woven Polypropylene Geotextile is normally made from polypropylene or polyester, which are long lasting and resistant to organic degradation and chemical reactions. They are designed to stand up to publicity to harsh environmental conditions, making sure long-term overall performance and minimal environmental impact.

4. How to Installation 8 Oz Non Woven Geotextile Fabric?

Installing 8 oz non woven geotextile fabric normally entails the following steps:

4.1 Preparation: Ensure that the subgrade floor is correct organized and graded in accordance to the task specifications. Remove any massive rocks, debris, or vegetation that may additionally intervene with the installation.

4.2 Unrolling the Fabric: Roll out the geotextile material alongside the organized surface, beginning from one stop of the region to be covered. Ensure that the cloth is founded and aligned properly.

4.3 Anchoring: Secure the geotextile fabric in location to forestall motion for the duration of and after installation. This can be executed by means of the usage of anchor pins or staples alongside the edges of the fabric. The spacing of the pins or staples relies upon on the precise assignment necessities and website conditions.

4.4 Overlapping: If more than one rolls of geotextile fabric are required to cowl the whole area, overlap adjoining rolls through a minimal distance as targeted in the task design. This overlapping ensures continuity and prevents gaps in the fabric.

4.5 Trimming: Trim the extra cloth as imperative to healthy round barriers such as pipes, structures, or irregularly formed areas. Ensure that the fabric is securely anchored round these features.

4.6 Securing Joints: If there are overlapping sections of geotextile fabric, impenetrable the joints by using stitching or warmness bonding them collectively as per the manufacturer's recommendations. This helps hold the integrity of the set up and prevents separation or transferring of the fabric.

4.7 Protection: Take measures to guard the set up 8 oz Non Woven Geotextile at some point of subsequent building activities. For example, cowl the cloth with a layer of soil or combination fabric to guard it from plausible injury precipitated with the aid of heavy equipment or traffic.

4.8 Quality Control: Conduct everyday inspections throughout and after set up to make certain that the geotextile material is excellent installed, undamaged, and functioning as intended. Make any critical changes or repairs as needed.

5. Advice on How to Guard Installed 8 Oz Non Woven Geotextile Fabric from Damage During Subsequent Construction Activities

5.1 Communication and Awareness: Ensure positive verbal exchange amongst the building team, contractors, and employees worried in subsequent building activities. Make them aware of the presence of geotextile and the significance of defending them throughout their work.

5.2 Site Planning and Sequencing: Plan the development things to do in a way that minimizes the practicable for harm to the set up geotextiles. Consider the area and timing of heavy machinery, cloth stockpiles, and different development operations to keep away from direct contact or immoderate stress on the geotextiles.

5.3 Physical Barriers: Install bodily obstacles or shielding covers, such as plywood or brief fencing, to defend the geotextile from doable harm induced with the aid of heavy machinery, building vehicles, or substances being transported throughout the area. Clearly mark the blanketed zones to make sure they are no longer by chance disturbed.

5.4 Proper Equipment Operation: Train operators of heavy equipment or gear to exercising warning and keep away from using over or immediately onto the geotextiles. Provide preparation on excellent tools operation methods to decrease the chance of geotextile damage.

5.5 Temporary Bridging: If development cars or gear want to move over the geotextile area, think about the usage of brief bridging techniques like metal plates or transient mats to distribute the load and shield the geotextiles from immoderate stress or puncture.

5.6 Regular Inspections: Conduct ordinary inspections of the geotextile set up at some stage in and after development things to do to discover any signs and symptoms of injury or displacement. Promptly tackle any problems by using repairing or reinforcing the geotextiles as necessary.

5.7 Supervision and Monitoring: Assign a accountable supervisor or task supervisor to oversee the building things to do and make sure compliance with geotextile safety measures. Monitor the building website often to stop inadvertent harm or deviations from the deliberate safety strategies.

5.8 Documentation and Reporting: Maintain documents of the geotextile installation, such as photographs, inspection reports, and any incidents or repairs. This documentation can be precious for high-quality manipulate functions and as proof in case of disputes or insurance plan claims.

6. Summarize

8 oz Non Woven Geotextile Fabric is a heavy-duty geosynthetic cloth made from extremely good polypropylene or polyester fibers via needle-punching or bonding. Weighing eight oz per rectangular yard (approximately 226 gsm), it presents outstanding strength, filtration, separation, and reinforcement capabilities. Its sturdiness and versatility make it best for purposes such as drainage systems, erosion control, street construction, landfill liners, and agricultural projects.

For reliable, high-performance geotextile solutions, BPM Geosynthetics presents premium-quality 8 oz non woven geotextile fabric tailor-made to your task needs—ensuring long-lasting overall performance and extremely good value.