Clay Liner Landfill

Clay liners offer excellent hydraulic sealing performance, chemical compatibility, and long-term durability. Their self-healing capability allows swelling clays like bentonite to seal small cracks or punctures, ensuring sustained impermeability. The materials are natural, cost-effective, and readily available, making them a practical choice for large-scale waste containment. With superior resistance to leachate pollutants and robust mechanical integrity, clay liners meet stringent environmental standards. When used alone or as part of composite liner systems, they provide reliable groundwater protection and extended service life, making them essential in modern landfill engineering.

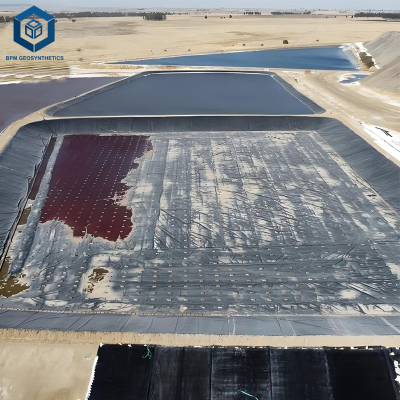

A Clay Liner in a landfill system serves as a critical barrier designed to prevent leachate migration into the surrounding environment. It forms an integral component of modern waste containment engineering, ensuring groundwater protection and compliance with environmental regulations. This article examines the technical properties, design principles, installation procedures, and regulatory standards of clay liners used in landfill applications.

What Is a Clay Liner?

A Clay Liner is a natural or engineered layer of low-permeability clay material placed at the base or sides of a landfill cell. Its primary purpose is to restrict fluid and contaminant movement, acting as a hydraulic barrier between waste and subsoil.

Typical clay materials include:

Bentonite clay (montmorillonite-rich)

Kaolinite clay

Illite or mixed-layer clays

The liner’s performance depends on mineral composition, compaction density, moisture content, and permeability characteristics.

Engineering Principles

Clay liners operate on hydraulic conductivity and diffusion control principles. When compacted properly, clay forms a dense matrix that restricts the flow of water and dissolved pollutants.

Key engineering parameters:

Permeability (k ≤ 1×10⁻⁷ cm/s): Ensures minimal leachate seepage.

Plasticity index (PI ≥ 15): Indicates flexibility under load.

Dry density: Typically 1.6–2.0 g/cm³ for optimal performance.

Thickness: Commonly 0.6–1.0 meters for base liners.

The design must balance hydraulic performance with structural stability, accounting for differential settlement, desiccation, and freeze-thaw cycles.

Regulatory Standards and Guidelines

Clay liners are governed by international and national standards that define design, material, and performance requirements.

Key regulations include:

US EPA 40 CFR Part 258: Minimum design criteria for municipal solid waste landfills.

ASTM D698 / D1557: Standard tests for soil compaction.

ASTM D5084: Test for hydraulic conductivity using flexible-wall permeameter.

EU Landfill Directive (1999/31/EC): Specifies base sealing and leachate control systems.

ISO 10722: Durability testing of geosynthetic–soil systems.

Compliance with these standards ensures long-term environmental protection and landfill stability.

Construction and Installation Procedures

1. Site Preparation:

Remove debris and organic matter; grade the surface to achieve uniform slope and stability.

2. Clay Material Selection:

Select locally available clay with appropriate plasticity, mineral composition, and low permeability.

3. Compaction:

Compact in layers (typically 150–200 mm thick) using sheepsfoot rollers or vibratory compactors. Maintain optimum moisture content (OMC ±2%) to prevent cracking.

4. Quality Control:

Perform field density tests, Atterberg limits, and permeability tests at each lift to ensure design compliance.

5. Integration with Other Liners:

Clay liners are often combined with geomembranes to form composite liner systems, significantly improving containment performance.

Engineering Challenges and Mitigation

Clay liners face potential issues such as desiccation cracking, root intrusion, and differential settlement.

Mitigation measures include:

Maintaining moisture balance through protective cover layers.

Using bentonite amendments to improve sealing ability.

Incorporating geosynthetic clay liners (GCLs) for enhanced consistency.

Monitoring groundwater and leachate through observation wells.

Performance Advantages

Clay liners offer excellent hydraulic sealing performance, chemical compatibility, and long-term durability. Their self-healing capability allows swelling clays like bentonite to seal small cracks or punctures, ensuring sustained impermeability. The materials are natural, cost-effective, and readily available, making them a practical choice for large-scale waste containment. With superior resistance to leachate pollutants and robust mechanical integrity, clay liners meet stringent environmental standards. When used alone or as part of composite liner systems, they provide reliable groundwater protection and extended service life, making them essential in modern landfill engineering.

Common Applications

Municipal solid waste landfills

Industrial hazardous waste containment

Mining tailings storage

Evaporation ponds and wastewater lagoons

Land reclamation and capping systems

Frequently Asked Questions

1. What is the ideal thickness for a clay liner?

Typically 0.6–1.0 m, depending on design requirements and local regulations.

2. Can clay liners alone prevent contamination?

While effective, combining clay with a geomembrane provides enhanced protection.

3. What causes clay liner failure?

Common causes include desiccation, poor compaction, root penetration, or chemical degradation.

4. How are clay liners tested for permeability?

Laboratory and field permeability tests (ASTM D5084, ASTM D2434) are used to confirm hydraulic conductivity.

5. Are clay liners environmentally sustainable?

Yes. They are made from natural materials, minimizing environmental impact while ensuring high containment performance.

Safety and Environmental Considerations

During construction and maintenance:

Avoid excessive drying or saturation of clay during installation.

Conduct regular inspections to detect settlement or cracking.

Follow environmental monitoring requirements per EPA and ISO guidelines.

Conclusion & Call to Action

A Clay Liner Landfill system represents a proven, environmentally sound solution for leachate containment and groundwater protection. Its low permeability, natural composition, and adaptability to composite designs make it indispensable in waste management engineering.

If you are planning a landfill construction or remediation project, we offer technical consultation, liner design optimization, and quality assurance support to ensure full regulatory compliance and long-term performance. Contact our engineering team for customized solutions that meet your environmental protection goals and project specifications.