What Is LLDPE Geomembrane And Its Applications?

LLDPE Geomembrane: Performance, Applications, and Market Insights

LLDPE geomembrane has become a critical material in global environmental engineering, water retention systems, mining containment, and agricultural infrastructure. Its balance of flexibility, strength, and chemical resistance makes it one of the most preferred geomembrane types for international project contractors, distributors, and industrial buyers. As demand for high-performance containment solutions rises, LLDPE geomembrane continues to secure a dominant role in modern geotechnical applications.

Industry Background and Rising Market Demand

The global geomembrane market has grown steadily as environmental regulations tighten and infrastructure investments increase. LLDPE geomembrane is particularly favored for complex installations requiring flexibility and durability. According to industry reports, the global demand for geomembranes is projected to expand at over 5% CAGR, with LLDPE gaining traction due to its adaptability in uneven terrain, resistance to cracking, and long service life.

Applications in mining, aquaculture, canal lining, solid waste management, and industrial wastewater containment are driving the adoption of LLDPE geomembrane. Buyers in North America, Europe, Latin America, and Southeast Asia increasingly specify this material for new and upgraded containment systems.

Technical Characteristics of LLDPE Geomembrane

LLDPE geomembrane is engineered from linear low-density polyethylene using advanced extrusion and calendering technologies. Its molecular structure provides a unique combination of tensile strength, elongation, flexibility, and chemical resistance. These performance qualities enable long-term containment even in extreme environmental conditions.

Flexibility and High Elongation

Compared with HDPE, LLDPE geomembrane offers significantly higher elongation, allowing it to adapt to differential settlement, irregular surfaces, and steep slopes. This flexibility reduces stress cracking and improves long-term reliability in unstable soil environments.

Chemical and UV Resistance

LLDPE geomembrane demonstrates strong resistance to acids, salts, industrial chemicals, and prolonged UV exposure. This makes it suitable for mining leach pads, wastewater lagoons, and outdoor reservoirs where long-term chemical exposure is expected.

Permeability and Mechanical Strength

The material maintains extremely low permeability, ensuring secure containment of liquids and preventing seepage losses. With excellent puncture resistance and tear strength, LLDPE geomembrane withstands installation stresses and heavy loads from soil cover or industrial operations.

Manufacturing Process Overview

LLDPE geomembrane production typically involves blown film extrusion or flat die extrusion. Raw material pellets undergo controlled melting, dispersion, and extrusion to form a uniform sheet. Quality inspection includes thickness accuracy, tensile performance, carbon black dispersion, and overall surface integrity. The sheets are then rolled, packed, and prepared for shipping to global project sites.

Key Application Sectors

Agriculture and Aquaculture

LLDPE geomembrane is widely used in fish ponds, irrigation reservoirs, farm effluent containment, and canal lining. Its flexibility simplifies installation in uneven agricultural sites and reduces long-term water loss.

Mining and Industrial Containment

Mining leach pads, chemical storage basins, and processing ponds rely heavily on LLDPE geomembrane due to its chemical resistance and high elongation properties. This ensures stable containment under dynamic loading conditions.

Landfills and Waste Management

In landfill liners and capping systems, LLDPE geomembrane provides essential protection against seepage while accommodating settlement of waste layers over time.

Water Infrastructure and Environmental Protection

LLDPE geomembrane is frequently used in reservoirs, liners, stormwater containment, wetlands restoration, and environmental remediation projects requiring long-term impermeability.

Market Trends and International Buying Insights

Several global trends are shaping the demand for LLDPE geomembrane. Stricter environmental regulations worldwide are increasing the need for impermeable lining systems. Infrastructure development in emerging markets continues to push the demand for durable containment materials. Additionally, buyers seek materials with third-party testing, traceability, and consistent mechanical performance.

Another notable shift is the preference for thicker LLDPE liners such as 1.0 mm, 1.5 mm, and 2.0 mm for large-capacity containment systems. At the same time, lightweight options such as 0.75 mm remain popular in agricultural and aquaculture projects due to cost-efficient installation.

FAQ: Common Questions from International Buyers

What is the typical lifespan of LLDPE geomembrane?

Under normal conditions, LLDPE geomembrane can last over 20 years. With proper UV stabilization and correct installation, service life can exceed 30 years.

Can LLDPE geomembrane be used in direct sunlight?

Yes. The material includes carbon black and UV stabilizers that allow long-term outdoor exposure without degradation.

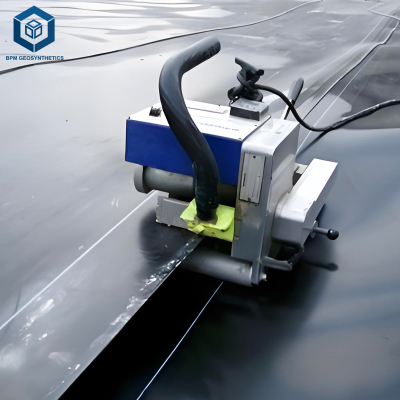

How is LLDPE geomembrane joined during installation?

Sheets are welded using hot wedge or extrusion welding equipment. Proper seam testing ensures impermeability and long-term reliability.

What thickness should buyers choose?

Thickness depends on application: 0.75–1.0 mm for aquaculture and agriculture, 1.5–2.0 mm for mining and landfills, and custom thicknesses for industrial containment.

Professional Call to Action

For global project contractors, distributors, and environmental engineering firms seeking reliable containment solutions, LLDPE geomembrane offers unmatched flexibility and long-term performance. We supply technical specifications, customization options, and international shipping support to help optimize your project. Contact our engineering team to access detailed data sheets, pricing, and professional guidance tailored to your application.