Geo Fabric

Global Industry Background of Geo Fabric

Geo Fabric, also known as geotextile fabric, has emerged as a critical material in civil engineering, landscaping, and environmental protection projects worldwide. Its role in soil stabilization, erosion control, and drainage systems has driven its adoption across infrastructure development, road construction, and sustainable landscaping initiatives. According to industry reports, the global geotextile market reached approximately USD 8.5 billion in 2024, with an expected compound annual growth rate (CAGR) of 6.3% through 2030.

The increasing demand for high-performance construction materials, coupled with rising urbanization and infrastructural investments in emerging economies, is fueling growth. Environmental regulations promoting soil conservation and sustainable construction further accelerate the use of geotextiles in both public and private projects.

Market Trends and Regional Insights

The adoption of Geo Fabric varies regionally. North America and Europe remain mature markets due to stringent construction standards and sustainability initiatives. Meanwhile, Asia-Pacific exhibits the fastest growth, driven by large-scale road networks, industrial parks, and land reclamation projects in China, India, and Southeast Asia.

Recent trends indicate a shift towards engineered nonwoven geotextiles, which offer superior tensile strength, filtration, and separation capabilities. Eco-friendly and recycled polymer-based fabrics are also gaining traction among environmentally conscious buyers, reflecting a growing emphasis on sustainability in procurement decisions.

Technical Parameters and Product Structure

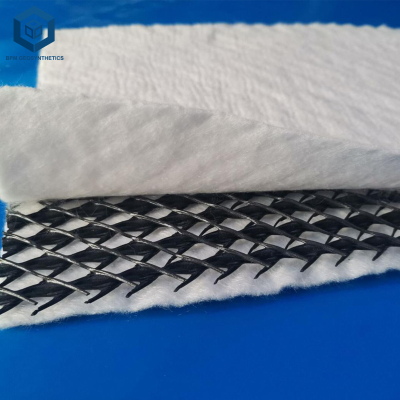

Geo Fabric is manufactured in woven, nonwoven, or knitted forms, each designed to meet specific performance requirements. Key technical parameters include tensile strength, puncture resistance, permeability, and elongation at break. Standard nonwoven fabrics typically range from 100 to 500 g/m², providing durability while maintaining flexibility for uneven terrain installation.

The product structure generally consists of polymer fibers such as polypropylene or polyester, thermally bonded or mechanically entangled to enhance dimensional stability. Some high-performance variants incorporate UV inhibitors, chemical stabilizers, or bi-component fibers for prolonged lifespan in outdoor conditions.

Manufacturing Process and Quality Control

The production of Geo Fabric involves extrusion, fiber opening, web formation, and bonding processes. Nonwoven fabrics are commonly manufactured through needle-punching or spunbond methods, ensuring uniform thickness and high tensile integrity. Quality control procedures include dimensional verification, tensile and tear testing, permeability evaluation, and accelerated UV exposure tests.

Advanced production facilities implement automated monitoring systems to maintain consistency, reduce material waste, and meet ISO 9001 quality standards. International buyers prioritize suppliers with traceable production processes and certifications, ensuring compliance with project specifications and regulatory requirements.

Applications and Buyer Preferences

Geo Fabric finds widespread application in road construction, railway embankments, drainage systems, landfill liners, slope stabilization, and landscaping. Buyers typically seek fabrics that balance mechanical performance with ease of installation and cost-effectiveness. Key procurement considerations include roll width and length, fabric weight, tensile strength, UV resistance, and compatibility with local environmental conditions.

International buyers often require product samples, detailed technical datasheets, and adherence to ASTM or EN standards to evaluate suitability for large-scale infrastructure projects. Customization options, such as specific weights or polymer types, can significantly influence purchasing decisions.

Challenges and Strategic Considerations

Despite strong growth, the Geo Fabric market faces challenges such as price volatility of raw polymers, competition from alternative stabilization materials, and variable regulatory environments across regions. Buyers are increasingly focused on total cost of ownership, including installation efficiency, lifespan, and maintenance requirements.

Strategic suppliers differentiate themselves by offering technical support, on-site installation guidance, and rapid sample delivery. Providing comprehensive documentation and compliance certifications enhances trust and facilitates procurement negotiations with multinational infrastructure developers.

Real B2B FAQs

Q1: What is the typical lifespan of a high-quality Geo Fabric?

A: Depending on the polymer type and environmental exposure, Geo Fabric can last 15–25 years, with UV-stabilized variants performing longer in direct sunlight.

Q2: Can Geo Fabric be customized for specific project requirements?

A: Yes, manufacturers can adjust fabric weight, tensile strength, polymer type, and roll dimensions to match project specifications and environmental conditions.

Q3: What standards should international buyers look for?

A: ASTM, EN, and ISO standards are commonly referenced to ensure mechanical performance, filtration efficiency, and environmental compliance.

Q4: How can we verify product quality before large-scale procurement?

A: Buyers typically request samples, technical datasheets, lab test reports, and certifications to evaluate suitability for their applications.

For global infrastructure projects seeking durable and high-performance geotextiles, we invite you to request detailed technical documentation, product samples, and competitive quotations to ensure your Geo Fabric requirements are fully met.