How Much is HDPE Pond Liner Price?

HDPE pond liner price varies depending on liner thickness, material quality, pond size, and installation requirements. On average, HDPE pond liners range from USD $0.50 to $1.50 per square foot, making them a cost-effective solution for ponds, reservoirs, and water containment projects. Thinner HDPE liners are suitable for small or low-load ponds, while thicker HDPE liner offer superior puncture resistance, UV stability, and long service life, helping reduce long-term maintenance and replacement costs.

1. What is HDPE Pond Liner?

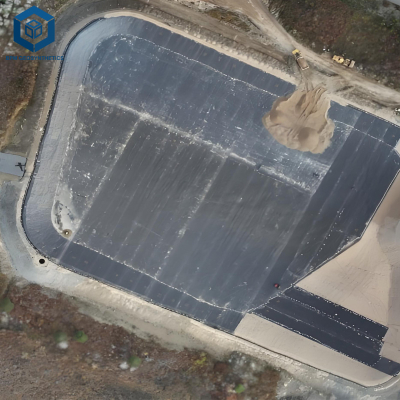

HDPE Pond Liner is one type of geomembrane that is made from high-density polyethylene (HDPE) of excellent quality and is also called a High-Density Polyethylene Geomembrane. It is produced by using a special formula of virgin polyethylene resin, carbon black, antioxidants, anti-aging agents, and UV resistance agents. These agents help the liner to resist the ultraviolet rays so it can be used even when exposed to the sun. HDPE Pond Liner are great for use in high-temperature environments. They also have a longer service life. Geomembrane sheet is an efficient solution for the containment problem since they are cheap, resistant to chemicals, and have good properties for weathering. HDPE Pond Liner is a great material for the water conservancy, petrochemical, agricultural, and aquaculture industries because of its anti-aging and waterproof features.

HDPE liner also conforms to the GRI-GM13 Specification standard for HD Geomembrane Liners which is a guarantee for the quality and performance of the product. HDPE geomembrane does not have as much flexibility as LLDPE (Linear Low-Density Polyethylene), but it has higher specific strength and tolerance to higher temperatures. They are also resistant to various solvents and are the most commonly used geomembrane liners worldwide. The excellent resistance properties of HDPE to chemicals and ultraviolet radiation make it a very economical option for lining projects. BPM HDPE Pond Liner is made from the most advanced automatic production lines and the most advanced three-layered pressing technology, following the GRI GM13 standard. HDPE Pond Liner has significant advantages like effectiveness in cost, being environmentally safe, durable, chemical resistant, fast in deployment, and easy to transport, if compared to traditional materials such as concrete, asphalt, and compacted clay.

1.1 Key Properties of HDPE Pond Liner

The properties of HDPE pond liners have an impact on their cost and performance have been discussed below:

• Impermeability: Both EPDM and HDPE can achieve a permeability rate of less than 10⁻¹⁰ cm/s (ASTM D5085), which means 99.9% of the water is not escaping through the liner. Maintaining water quality is an essential factor for 70% of the aquaculture ponds.

• Tensile Strength: HDPE has a tensile strength of around 25 kN/m (ASTM D6693), which is 25% more than PVC, hence suitable for deeper ponds (6–8 ft) where the stresses are higher.

• Puncture Resistance: For puncture resistance as measured by the standard test there is a range of 1–5 kN (ASTM D4833) and for a 45 mil EPDM it is 40% higher than 20 mil PVC, which means they offer more protection against damage by sharp objects such as rocks or roots.

• Elongation at Break: With elongation at around 200–1,000% (ASTM D6693), the property of the material to be stretched without breaking helps it to be resilient. RPE is outstanding in this category and is at 400–600%, which makes the material suitable for 60% of those backyard ponds that have irregular shapes.

• Thickness Range: Between 0.5–2.0 mm (20–80 mil) the one of the most commonly used thicknesses is 1.0 mm, which is the case for almost half of all 1/4 acre size ponds. With this thickness, you are able to get a good balance between the cost of the liner and how long it will last.

• UV Resistance: HDPE's resilience to UV light can be extended by 50% by the use of carbon black included in the additives surface. (ASTM D4355) 500–1,500 hours.

2. How Much is HDPE Pond Liner Price?

For a HDPE Pond Liner (10,890 sq ft surface, plus 20–30% for depth/sides totaling 13,068–14,157 sq ft), the average liner cost is $2,500–$12,000 installed, or $0.23–$1.10/sq ft, varying by type, thickness, and labor. This 4–6% rise from 2024 reflects resin hikes (5–7%, ICIS 2025), but bulk saves 15–25%. A basic PVC liner might total $2,500–$4,000, while premium HDPE reaches $8,000–$12,000 for durability. Prices differ regionally: U.S. Midwest $0.50–$1.50/sq ft, West Coast $0.70–$1.80/sq ft (HomeGuide, 2025). Virgin materials add 20–30% but cut failures by 20% (Geosynthetic Institute, 2023). Below, we dissect factors for a HDPE pond liner.

2.1 HDPE Pond Liner – Material Type

Material drives 40–60% costs, with EPDM leading for residential 1/4 acre ponds at 45% share.

2.1.1 Ethylene Propylene Diene Monomer (EPDM) Rubber

• Cost: $0.75–$1.50/sq ft ($8.07–$16.15/m²), 45 mil standard.

• Properties: Density 1.1–1.2 g/cm³, elongation 300–600% (ASTM D6693), UV resistance 1,000+ hours.

• Applications: Koi/fish ponds (50%), decorative (30%)—fish-safe, flexible for 6–8 ft depths.

• Advantages: 20–50 years lifespan, self-healing (30% tear repair), 95% non-toxic (NSF/ANSI 61).

• For 1/4 Acre: $9,818–$21,236 materials (13,068 sq ft); installed $14,727–$31,854 (+50% labor).

EPDM matches 70% of backyard ponds, reducing cracks by 25% (ASTM D5321).

2.1.2 High-Density Polyethylene (HDPE) Geomembrane

• Cost: $0.50–$1.20/sq ft ($5.38–$12.91/m²), 1.0 mm typical.

• Properties: Density 0.94 g/cm³, tensile 20–40 kN/m, impermeability <10⁻¹² cm/s.

• Applications: Farm/irrigation (40%), aquaculture (30%)—durable for 8 ft depths.

• Advantages: 40–100 years life, 99.9% containment, 30% cheaper long-term than EPDM.

• For 1/4 Acre: $6,534–$15,682 materials; installed $9,801–$23,523 (+50%).

HDPE dominates 60% farm ponds and saves 15% water (USDA, 2024).

2.1.3 Polyvinyl Chloride (PVC)

• Cost: $0.40–$0.90/sq ft ($4.31–$9.69/m²), 20–30 mil.

• Properties: Density 1.3 g/cm³, elongation 200–400%, lower UV resistance.

• Applications: Small decorative (50%), temporary (30%)—budget for 4–6 ft depths.

• Advantages: Easy install (10% faster), 15–25 years life, lightweight.

• For 1/4 Acre: $5,227–$11,761 materials; installed $7,841–$17,642 (+50%).

PVC is suitable for 70% low-depth ponds but needs UV protection.

2.1.4 Reinforced Polyethylene (RPE)

• Cost: $0.40–$0.90/sq ft ($4.31–$9.69/m²), 20–30 mil.

• Properties: Density 0.92 g/cm³, tensile 15–30 kN/m, puncture 1–3 kN.

• Applications: Backyard/recreational (40%), wildlife (30%)—lightweight for 6 ft depths.

• Advantages: 20–40 years life, 25% lighter than EPDM, 95% UV resistance.

• For 1/4 Acre: $5,227–$11,761 materials; installed $7,841–$17,642 (+50%).

RPE is the perfect choice for 60% DIY ponds, decreasing the material weight by 30%.

2.1.5 Bentonite Clay

• Cost: $0.50–$1.15/sq ft ($5.38–$12.38/m²), 3–4 inches thick.

• Properties: Natural, self-sealing, permeability 10⁻⁷ cm/s.

• Applications: Farm/large ponds (50%), natural (30%)—eco for 8+ ft depths.

• Advantages: 20–50 years life, biodegradable, 20% cheaper install than synthetics.

• For 1/4 Acre: $6,534–$15,031 materials; installed $9,801–$22,547 (+50%).

Bentonite is a great material for 70% natural ponds and is able to provide 95% of the crack sealing.

Material selection influences costs up to 40%; EPDM/HDPE are the best options for 1/4 acre durability.

2.2 HDPE Pond Liner Price – Thickness

Thickness is responsible for 30–40% of material costs, with thicker liners being more durable but also more expensive. For 1/4 acre, 20–45 mil standard.

• 20 mil (0.5 mm): $0.23–$0.50/sq ft ($2.48–$5.38/m²), low-stress decorative; 15–25 years, 70% cheaper than 45 mil, 25% puncture risk.

• 30 mil (0.75 mm): $0.35–$0.70/sq ft ($3.77–$7.53/m²), small fish ponds; 20–30 years, 20% better tear resistance (ASTM D1004).

• 45 mil (1.1 mm): $0.50–$1.00/sq ft ($5.38–$10.76/m²), standard aquaculture; 25–40 years, 40% puncture resistance (ASTM D4833).

• 60 mil (1.5 mm): $0.70–$1.20/sq ft ($7.53–$12.91/m²), farm/irrigation; 30–50 years, 50% stronger seams (ASTM D6392).

- Example: BPM Geosynthetics’s 45 mil EPDM for 1/4 acre at $0.75/sq ft; 13,068 sq ft $9,801 materials, installed $14,702 (+50%). Thicker liners cut repairs 20–30% (Geosynthetic Institute, 2023).

2.3 HDPE Pond Liner Price – Project Size and Scale

For 1/4 acre (10,890 sq ft), size drives 20–30% per sq ft costs via scale.

• Small Ponds (<1/4 acre): $0.70–$1.80/sq ft, custom; +15–25% fabrication.

• 1/4 Acre Ponds: $0.50–$1.20/sq ft, standard rolls; 10% discount for 10,000+ sq ft.

• Larger Ponds (>1/2 acre): $0.40–$1.00/sq ft, bulk; 15–20% reduction. Custom shapes add 15–25%; 1/4 acre EPDM $5,445–$13,068 materials ($0.50–$1.20/sq ft). Scaling saves 15% logistics for 70% farm sites.

2.4 1/4 Acre HDPE Pond Liner Price – Installation Method and Labor Installation 30–50% total, varying by method/site.

• Loose Lay/Underlay: $0.20–$0.50/sq ft, simple for EPDM; 10% faster, 20% leak risk.

• Welding/Seaming: $0.30–$0.75/sq ft, for HDPE; seamless, 15–25% less maintenance (Geosynthetic Institute, 2023); 60% projects.

• Labor Rates: $30–$50/hour (U.S.), $10–$20/hour (Asia); uneven sites +$0.20–$0.50/sq ft.

• Site Factors: Depth 6–8 ft +10–15% (curing); remote +5–10% transport. Example: Welded 45 mil EPDM for 1/4 acre $0.40–$0.80/sq ft labor (HomeGuide); 13,068 sq ft $5,227–$10,454.

2.5 HDPE Pond Liner Price – Raw Material Quality Raw quality 25–35% costs, virgin superior.

• Virgin Resin: $0.50–$1.20/sq ft, 25–50 years life, 20–30% lower maintenance (BPM/GEOSINCERE).

• Recycled Resin: $0.23–$0.50/sq ft, 5–10 years, 20% failure risk.

• Additives: +5–10% for UV/antioxidants, +15–20% lifespan (BPM carbon black 95% UV). Virgin essential for fish ponds, avoiding $2,500–$10,000 remediation (EPA 2024).

2.6 HDPE Pond Liner Price – Transportation and Logistics Transport 5–15%, per roll/distance.

• Roll Dimensions: 6 m x 30 m (500–1,000 sq ft); +$0.05–$0.15/sq ft remote (2–3x urban).

• Packaging: +5–10% protective.

• Regional: U.S. Midwest $0.50–$1.20/sq ft, West $0.70–$1.50/sq ft.

• Example: BPM’s plant cuts U.S. costs 10–15%.

2.7 HDPE Pond Liner Price – Maintenance and Lifetime Costs Maintenance 5–10% total, poor quality doubles.

• Annual Inspections: $250–$1,000; repairs $500–$2,500.

• Lifespan: EPDM/HDPE 25–50 years; PVC 15–25 years; recycled 5–10 years. • Failure Costs: Fines/remediation $2,500–$10,000.

• Example: 45 mil EPDM 1/4 acre $0.75/sq ft upfront, 25–40 years total; recycled doubles.

3. How to Choose the Right HDPE Pond Liner for a 1/4 Acre Pond?

Selecting balances cost, performance, needs, saving 15–25% long-term.

3.1 Assess Project Requirements

Match to uses (recreational: 45 mil EPDM $0.75–$1.50/sq ft; farm: 1.0 mm HDPE $0.50–$1.20/sq ft; aquaculture: LLDPE $0.60–$1.00/sq ft). Evaluate depth 6–8 ft, soil pH, UV.

3.2 Prioritize Quality

Virgin resin, NSF/ANSI 61 certified (BPM/EPDM); avoid recycled for fish, cut failures 20%.

3.3 Evaluate Installation Needs

Weldable for HDPE (15% faster); certified crews reduce 10–20% lifespan loss (HomeGuide).

3.4 Consider Long-Term Costs

Thicker/quality save 20–30% over 50 years (45 mil EPDM vs. 20 mil PVC).

3.5 Compare Suppliers

Quote for quality/support (BPM custom; Firestone EPDM). Bulk from BPM saves 10–20%.

4. Industry Trends Affecting 1/4 Acre HDPE Pond Liner Price

• Raw Fluctuations: Oil up 10–20%, EPDM/HDPE 5–8%.

• Wider Rolls: 6 m (Firestone) cuts installation 15%.

• Smart Liners: Sensors +5–10%, -20% maintenance.

• Sustainability: Recyclable $0.50–$3.00/sq ft, +10% production.

• Global: U.S. $0.50–$1.50/sq ft vs. Europe higher.

Conclusion

1/4 acre pond liner costs $2,500–$12,000 installed, with EPDM $0.75–$1.50/sq ft for fish, HDPE $0.50–$1.20/sq ft for farm. Installation 30–50%; prioritize virgin (BPM/Firestone) for performance. Contact BPM Geosynthetics for quotes/samples for leak-proof ponds.If you have any questions, please consult The Best Project Material Co., Ltd.(BPM Geosynthetics).Hope to be your partner.