What is Geonet HDPE and its Applications?

Geonet HDPE is a type of geosynthetic that has been widely used in various civil engineering and environmental works. Geonet HDPE, thanks to its distinct three-dimensional shape and great material properties, is capable of providing drainage, filtration, and reinforcement solutions in a variety of fields. In this paper, we review the material and properties of Geonet HDPE and its numerous industrial applications, thereby highlighting its indispensability to sustainable infrastructure development.

1. What is Geonet HDPE?

Geonet HDPE refers to a geosynthetic, high-performance drainage material that is made of high-density polyethylene (HDPE) polymer of superior quality. The product boasts a 3D framework which is the result of the crossing and extrusion of ribs that give the material a tough and steady open mesh.This ingenious architecture produces perpetual pathways for the swift movement of liquids and gases, thereby granting drainage and ventilation facilities even at the time of heavy loads.

Since HDPE exhibits an excellent resistance to chemicals, UV rays, and allows for a long life, Geonet HDPE can be counted on to deliver the intended results even when used in harsh environments such as landfills, mining sites, road construction, and environmental protection projects.

Geonet HDPE is usually utilised in combination with geomembranes or geotextiles so as to create composite drainage systems that can improve filtration, separation, and leakage control.Thanks to its high compressive strength and long service life, Geonet HDPE is instrumental in enhanced system performance and decreased maintenance costs in the field of civil and geotechnical engineering.

2. Key Characteristics of Geonet HDPE

2.1 High Tensile Strength and Long-Term Durability

The triple dimensional rib framework that is inflexible in nature is the means by which Geonet HDPE can give the most excellent tensile strength coupled with the highest load-bearing capacity.

Having been reinforced with such a design, the material is able to resist deformation, crushing, and creep under heavy soil pressure, traffic loads, and structural stress. However, the story does not end here as even in unfavorable scenarios such as landfills, mining facilities, and highway embankments, Geonet HDPE continues to deliver drainage performance at a stable level for a long time due to the fact that it keeps its structure intact.

2.2 Excellent Chemical and Corrosion Resistance

Being a product of high-quality polyethylene, Geonet HDPE is extremely resistant to multiple substances such as acids, alkalis, salts, and hydrocarbons. Such chemical stability will mean that the material will not degrade when it is in contact with contaminated soils, leachate, and industrial waste.

Moreover, the material offers damage control for the external environment when, given that undergoes treatment in a landfill, sewage treatment plant, or hazardous waste containment area. This level of resistance extends to any damages caused by corrosion and therefore is practical in long-term usage which is necessary in such facilities.

2.3 Superior Hydraulic Conductivity and Drainage Efficiency

The unique feature of Geonet HDPE that are the ribs intersecting with one another creates channels that provide a continuous flow. The channels give water, leachate, and gases the freedom and rapidity to move. Geonet HDPE possesses a very high level of hydraulic conductivity which results in a drastic lowering of hydrostatic pressure and prevention of waterlogging.

Furthermore, a smart and well-functioning drainage system can contribute to the reduction and prevention of a myriad of unwanted phenomena such as soil erosion, slope instability, and inevitable damage to the foundation.

2.4 UV Resistance and Extended Service Life

In order to resist the effects of ultra-violet rays, Geonet HDPE has been endowed with ultraviolet stabilizers and antioxidants to keep it from breaking down. The good thing about UV resistance is that it not only allows for performance but also for longevity whether the product is protected or exposed.

Geonet HDPE was manufactured to be resistant to thermal aging and oxidation hence, it provides extensive use opportunities which can be enjoyed for several decades after proper installation.

2.5 Lightweight Structure and Easy Installation

Geonet HDPE compared to common drainage materials such as gravel and sand is much lighter and more flexible. Because it is light, the material lowers the costs of transportation and makes the handling works easier on the construction site. The material can be cut, positioned, and installed in no time with a minimal use of equipment and labor. Due to this ease of installation, the construction duration is shortened, the costs of the whole project go down, and the drainage performance is kept at a high level.

3. Geonet HDPE Manufacturing Process

3.1 Raw Material Selection and Preparation

The manufacturing of Geonet HDPE involves the initial step of selecting High-density polyethylene (HDPE) resin of high quality. Usually, to achieve consistent mechanical strength, chemical resistance and durability, 100% virgin or recycled premium-grade HDPE is used. Compounds such as antioxidants, UV stabilizers and processing aids are mixed with the raw material to improve aging resistance and environmental performance. Then, the mixture is dried and purified before extrusion.

3.2 Melting and Extrusion Forming

In the next step, the HDPE resin is directed into a sophisticated extrusion device and subjected to heat until reaching a smooth, viscous molten state. Subsequently, the melted polymer is pushed through specialized dies, which give it the shape of a continuous grid-like rib pattern. The extrusion process accurately shapes the ribs that cross the ribs creating open channels for drainage, thus, both geometrical uniformity and optimal flow paths are guaranteed.

3.3 Rib Bonding and Structural Reinforcement

Once extruded, the ribs that cross each other are welded thermally by means of heating and pressure methods. The thermal fusion entails the strengthening of the bonds between different ribs which leads to higher tensile strength and better dimensional stability. Apart from that, good bonding ensures the areas of stress concentration are free from separation, deformation, and collapse and hence the level of drainage capacity of the geonet is kept at the same level after being exposed to loads for an extended period.

3.4 Cooling, Shaping, and Dimensional Control

The fresh geonet shape goes through a cooling process, either by air or water, to get its shape fixed and to avoid the buildup of internal stress. At that time, the use of precision rollers and tension control equipment helps achieve the accurate thickness, rib spacing and flatness of the sheet. Monitoring is done by a sophisticated system that keeps checking the geometric features against the set machine tolerance throughout the process so that the product meets international quality standards.

3.5 Customization and Performance Optimization

The present-day plants are well-equipped and can readily adapt the characteristics of different geonets for specific projects. Not only can the rib angle or spacing be changed, but also parameters like thickness, aperture size, and flow capacity, all these can be done to have a perfect match for different drainage, filtration, and ventilation requirements. By doing so, the product's performance can be maximized in the applications of landfills, mining, roadways, and environmental protection systems.

3.6 Quality Inspection and Testing

Each batch of Geonet HDPE is subject to quality inspection and testing in laboratories before packaging. The physical and chemical characterizations of the samples such as tensile strength, compressive resistance, hydraulic transmissivity, and chemical stability are tested using international standards (ASTM, ISO, or EN). Only those products which are able to comply with the standards are approved and allowed to be released into the market.

3.7 Cutting, Packaging, and Storage

Once final approval is given, the rolls of geonet are sliced to meet the required sizes and packed using the materials which resist moisture and UV radiation. Accurate details such as product type, size, batch number, and technical data of the product for traceability are included in the labeling. The products are kept in environmentally controlled warehouses so as to be protected from dust, moisture, and mechanical damage until they are dispatched to the customers.

4. What is BPM Composite Geonet HDPE?

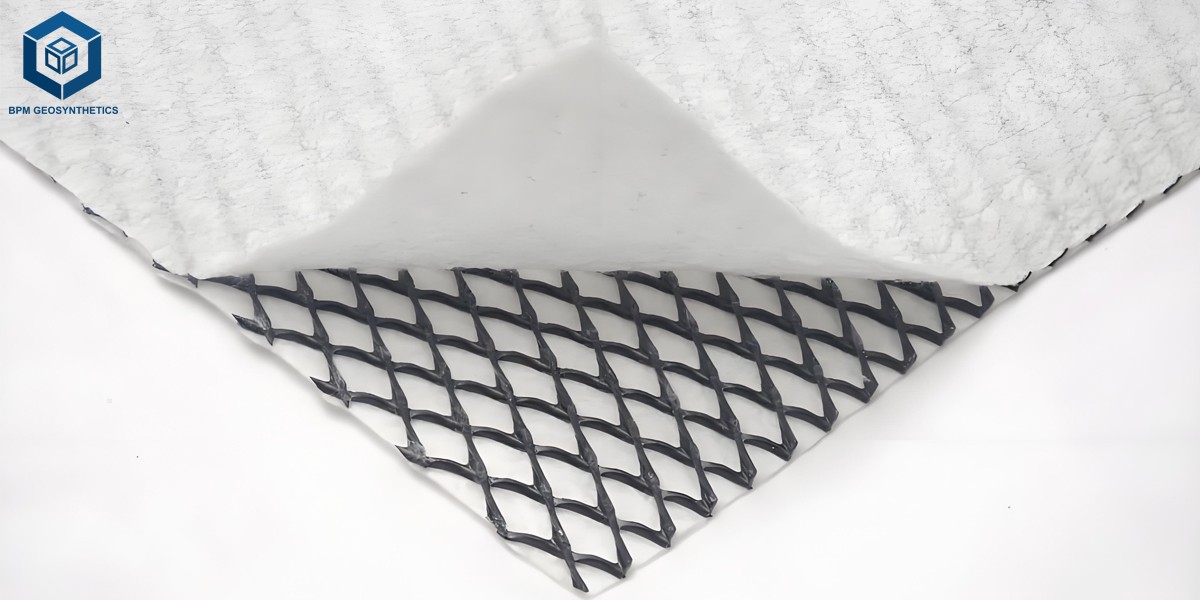

BPM Composite Geonet HDPE is a top-quality drainage system that combines a geonet core made of HDPE with two layers of geotextile fabric. Hence, the final product performs filtration, drainage, separation, and protection functions all at once. The core used for drainage is made by extruding high-density polyethylene mixed with carbon black, UV stabilizers, and antioxidants to improve the material's durability and resistance to aging. Its 3D interwoven structure creates the drainage channels that have high water flow capacity vertically as well as horizontally. The outer layers of the geotextile stop the soil from the core getting clogged while at the same time they protect the core from abrasions. This innovative double-layer structure is an effective solution of 'inverted filter–drainage–protection' that is frequently installed in landfills, roads, tunnels, retaining walls, and other environmental engineering projects.

5. BPM Composite Geonet HDPE Technical Data

Property | unit | BC63/D200 | BC70/D200 | BC80/D200 | BC90/D200 | Test Standard |

Geocomposite specification | ||||||

Hydraulic conductivity(MD) | ㎡/s | 2.8×10−³ | 3.2×10-³ | 4.0×10-³ | 5×10-³ | ASTM D4716 |

Puncture Resistance | kN/m | 0.17 | 0.17 | 0.17 | 0.17 | ASTM D7005 |

Core Material Geonet Specification | ||||||

Thickness | mm | 6.3 | 7 | 8 | 9 | ASTM D5199 |

Density | g/cm³ | 0.94 | 0.94 | 0.94 | 0.94 | ASTM D1505 |

Carbon Black Content | % | 2 | 2 | 2 | 2 | ASTM D1603 |

Tensile strength(MD) | kN/m | 8 | 10 | 12 | 14 | ASTM D7179 |

Hydraulic conductivity(MD) | ㎡/s | 2.0×10-4 | ASTM D4716 | |||

Geotextile Specification | ||||||

Unit weight | g/㎡ | 200 | 200 | 200 | 200 | 200 |

Geotextile type | Continuous filament non-woven geotextile | |||||

6. Applications of Geonet HDPE

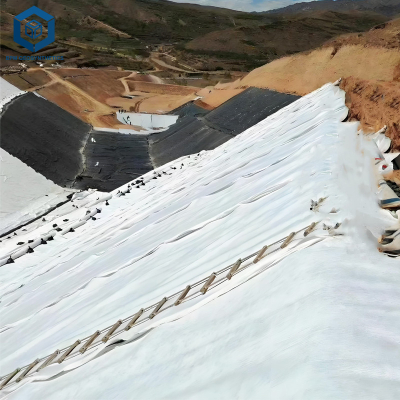

6.1 Landfill Engineering

Geonet HDPE plays a vital part in landfills nowadays. The major functions include:

- Leachate Collection Systems – Efficiently channeling leachate to collection pipes to avoid contamination of the environment by harmful liquids.

- Gas Venting Layers – Allowing methane release from the landfill which can be utilized for generating energy.

- Composite Liners – Coping with geomembrane for better leak detection and protecting the surroundings from pollutants.

6.2 Transportation Infrastructure

Inroads, railways, airports runways, and Geonet HDPE are the perfect match to increase the performance and the service life of these facilities by:

- Subsurface Drainage – Avoiding water accumulation under pavements that cause frost heave and cracking issues.

- Separation & Stabilization – Functioning as a separator layer between subgrade and aggregate layers thus preventing mixing.

- Erosion Control – Employed in embankments and retaining walls that support slope stability.

6.3 Mining & Industrial Applications

Geonet HDPE can be used to solve problems in mining:

- Heap Leach Pads – Providing drainage functions in gold and copper extraction operations.

- Tailings Management – Limiting the entrance of water and thus guaranteeing the safe storage of tailings.

- Secondary Containment – Guarding against leakages and spills inside a facility.

6.4 Water Management Systems

- Retention Ponds & Stormwater Drainage – Helps water to move easily in urban water drainage systems.

- Green Roofs & Vertical Gardens – Serves as a lightweight drainage solution that fits well with environmentally friendly buildings.

- Irrigation & Agricultural Drainage – Facilitates root respiration and inhibits soil saturation in farmlands.

6.5 Coastal & Hydraulic Engineering

- Shoreline Protection – Acts as a buffer layer in synthetics breakwaters and revetments designed to resist erosion.

- Dam & Canal Liners – Maintenance of good water flow along with prevention of water infiltration.

7. Geonet HDPE Future Trends & Innovations

Geonet HDPE will become more and more popular as:

- New Infrastructure Development – The resettlement of people in the outskirts of cities and beyond and transportation projects is growing.

- Environmental Regulations – Imposing stricter rules on landfills and mines waste handling.

- Advances in Polymer Technology – Producing biodegradable and recycled HDPE grades.

In a Nutshell

Geonet HDPE proves to be a multi-purpose and necessary item for contemporary engineering. It provides drainage, filtration, and reinforcement solutions in a variety of fields. When looking at its implementations in landfills, transportation, mining, and water management, one must admit that it is quite resourceful and efficient. With sustainability being a major global concern, The Best Project Material Co., Ltd.(BPM Geosynthetics) Geonet HDPE is the one that will keep on having an influence on creating durable and environment-friendly infrastructure.