Ultmate Guide to Choosing Best Geocell

Best Geocell have turn out to be a game-changer in civil engineering, soil stabilization, erosion control, and load assist applications. Whether you are working on street construction, slope reinforcement, or landscaping, choosing the proper geocell material is imperative for long-term sturdiness and cost-effectiveness.

As a manufacturer of geocell, BPM Geosynthetics Company can furnish you with product materials, dimensions, and standards, and can offer you the appropriate materials and professional solutions for different projects.

1. The Structure and Working Principle of Best Geocell

1.1 Best Geocell Material and Structure

Geocell structures are typically made from high density polyethylene (HDPE) , PP and PET etc. These materials offers excellent abrasion resistance, chemical stability, resistance to photo-oxidation aging, and acid-alkali resistance, making it suitable for a wide range of soil and environmental conditions.

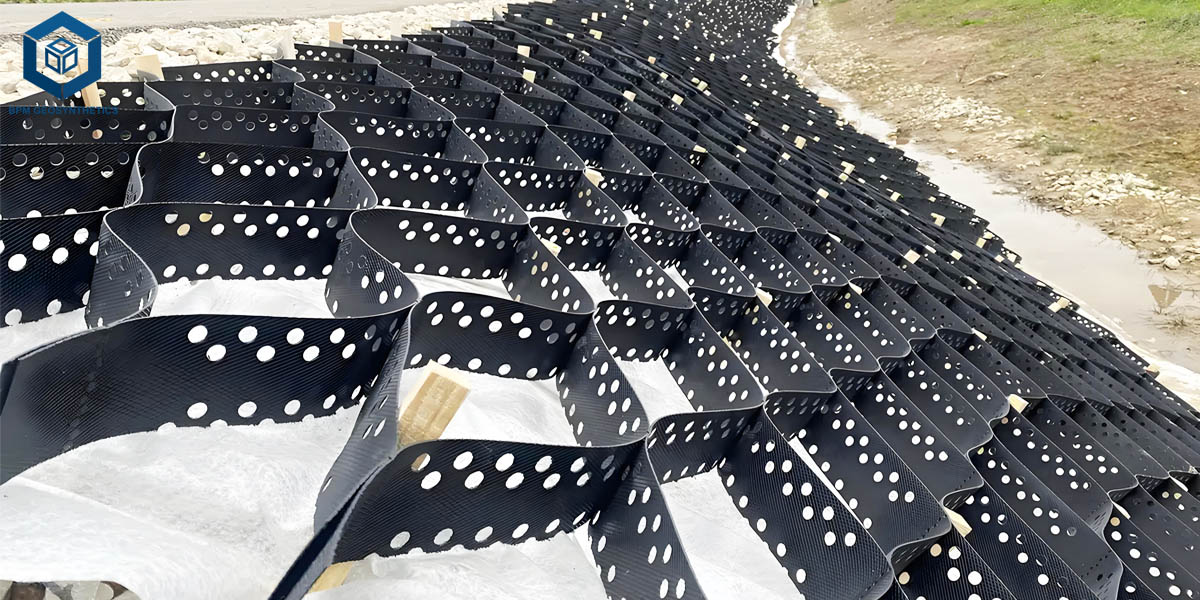

The geocell erosion control structure is a honeycomb shaped three-dimensional mesh, consisting of multiple reinforcing strips connected to each other at multiple junctions to form multiple cells. This structure can be folded during transportation and stretched into a mesh during construction.

1.2 Working Principle of Best Geocell

1.2.1 Lateral constraint effect: The geocell slope protection provides significant lateral constraint on the filling material, and the sidewalls of the grid generate upward frictional support force on the filling material, forming a composite with high bending and tensile stiffness and shear strength. This constraint can effectively suppress the lateral deformation of the filler and improve the stability of the overall structure.

1.2.2 Stress diffusion and improvement of bearing capacity: When a load is applied to the surface of the foundation, the geocell ground grid paver uniformly distributes the load over a larger area through its three-dimensional confinement effect. At the same time, the friction between the filling material inside the compartment and the compartment wall, as well as the stiffness of the compartment itself, jointly improve the bearing capacity of the foundation.

1.2.3 Isolation and coordinated deformation: Geocell HDPE can isolate the transmission of stress and displacement, allowing for flexible transitions of loads between different areas. For example, in a semi filled and semi excavated roadbed, it can coordinate the settlement of the top surface and reduce the occurrence of uneven settlement.

2. Key Factors in Choosing Best Geocell

2.1 Characteristics of the 3 Sorts of Best Geocell Materials

- High-Density Polyethylene (HDPE) Geocell: Resistant to chemical corrosion and UV rays, appropriate for long-term publicity environments (such as slope protection).

- Polypropylene (PP) Geocell: High rigidity, appropriate for eventualities with excessive load-bearing necessities (such as street bases).

- Polyester (PET) Geocell: High tensile strength, however terrible alkali resistance, so it wishes to be chosen in accordance to the soil environment.

2.2 The Demand for Best Geocell in Engineering Applications

- Best Geocell Load capacity: For traffic loads such as road parking lots, high-strength and deep geocell (usually ≥ 10cm in height) must be selected to ensure they can withstand frequent and heavy vehicle traffic pressure. For light load applications, such as green slope protection, relatively shallow geocell gravel driveway specifications (5-10cm) can be chosen, which can meet the needs and be economically practical.

- Best Geocell Slope stability: In slope engineering, geocell slope erosion control need to be designed with anchoring and materials with UV resistance should be selected to ensure long-term stability.

- Best Geocell Erosion control: In areas prone to soil erosion, geocell pavers with small aperture and low height should be selected to fix the surface soil through their tight structure, effectively preventing erosion.

2.3 The Influence of Cell Size and Depth of Best Geocell on Performance

The cell size (welding distance) and depth (cell height) of a Geocell directly affect its load distribution capacity, stability, and applicable scenarios:

2.3.1 The influence of geocell size (aperture):

- Small aperture (such as 20 × 20cm): Enhances the constraint force on filling materials (such as gravel), improves overall stiffness, and is suitable for high load-bearing requirements (such as road base).

- Large aperture (such as 40 × 40cm): Conducive to drainage and vegetation growth, suitable for ecological slope protection or erosion control engineering.

2.3.2 The influence of geocell depth:

- Deeper compartments (15-30cm): Can accommodate more filling materials, significantly improving compressive strength, suitable for soft foundation reinforcement or heavy loads (such as high fill and dock foundations).

- Shallow cells (5-10cm): Provides surface stability and is suitable for light load scenarios (such as parking lot base and green belt protection).

2.4 Best Geocell Filling Material

Gravel is a commonly used filling material that has good drainage performance and can effectively prevent water accumulation, but it may not be visually appealing. Soil is more suitable for greening projects, as it can support vegetation growth and enhance aesthetics, but its permeability is relatively poor and may require additional drainage measures. Grass filling combines aesthetics and certain ecological functions, suitable for landscape engineering, but requires regular maintenance such as pruning and watering. Different filling materials not only affect the functionality of plastic geocell, but also have a significant impact on the overall effectiveness and long-term maintenance of the project.

2.5 Best Geocell Bearing Capacity

For transportation facilities such as roads and parking lots, it is necessary to ensure that geocell can withstand frequent vehicle traffic and heavy load pressure. This not only includes the static weight of the vehicle, but also considers the influence of dynamic loads, such as the impact force generated when the vehicle is in motion. In addition, other possible traffic loads should also be considered, such as temporary passage of heavy equipment or additional loads during construction. Only by selecting HDPE geocell with sufficient load-bearing capacity can the long-term stability and safety of the project be ensured.

2.6 Best Geocell Installation environment and climate conditions.

Firstly, it is necessary to evaluate the soil type, slope, and drainage mode conditions on site, as different environments may require special Geocell design or installation techniques. For example, in areas with steep slopes, one of a kind anchoring techniques may additionally be required to make sure the balance of the perforated geocell; In areas with negative drainage, it is essential to select filling substances with appropriate drainage performance. At the identical time, it is crucial to consider the nearby local weather conditions, such as intense temperature values, rainfall, and snowfall. Choosing Geocells that can stand up to these climatic stipulations for a lengthy time, such as substances that continue to be steady in excessive or low temperature environments, and merchandise with exact sturdiness in excessive rainfall areas, can make certain that slope protection geocell can operate at their excellent for the duration of their whole lifespan.

3. Best Geocell Installation and Maintenance

3.1 Best Geocell Installation Guide: A well-prepared and certain set up guide is critical to make sure the highest quality overall performance of a Geocell system. The technique usually starts offevolved with thorough floor preparation, which entails leveling the site, casting off debris, and compacting the subgrade to meet sketch specifications. Next, the connection of geocell slope erosion control devices have to comply with the manufacturer’s advocated methods, such as the usage of staples, pins, or interlocking mechanisms, to obtain steady alignment and forestall deformation all through filling. The filling stage requires cautious decision of appropriate materials—such as aggregates, soil, or recycled fillers—and uniform distribution to acquire full compaction inside every cell. By following every step exactly and adhering to the technical requirements, the set up method can be carried out smoothly, making sure structural steadiness and long-term performance.

3.2 Best Geocell Maintenance Suggestion: To lengthen the carrier lifestyles of geocell systems, normal inspections need to be performed to observe any loss or displacement of the filling materials, as nicely as signs and symptoms of agreement or erosion. It is additionally essential to investigate the standard structural integrity, paying unique interest to areas uncovered to heavy loads, water flow, or environmental stress. Prompt restore or substitute of broken or worn aspects will no longer solely keep the system’s effectiveness however additionally decrease the danger of luxurious future interventions, making sure non-stop performance in a variety of operational conditions.

4. Environment and Sustainability

4.1 Environmental Advantages: Plastic geocell structures can comprise recyclable or domestically sourced materials as infill, correctly minimizing the reliance on standard asphalt or concrete paving methods. This strategy no longer solely reduces the consumption of finite herbal assets however additionally helps minimize the carbon footprint related with transportation and fabric production. Furthermore, the inherent porous shape of Geocell enhances rainwater infiltration into the soil, assisting to fill up groundwater, mitigate floor runoff, and decrease the probability of flooding. By maintaining herbal water cycles and minimizing erosion, Geocell contributes to the long-term fitness of surrounding ecosystems.

4.2 Sustainable Development: Beyond their structural benefits, Geocell options play a essential position in helping inexperienced and sustainable development practices. By controlling soil erosion, optimizing stormwater drainage systems, and advertising vegetation increase thru the stabilization of slopes and embankments, they make a contribution to resilient landscapes that combine harmoniously with the environment. This makes Geocell an perfect desire for eco-conscious projects, from inexperienced city infrastructure and riverbank restoration to toll road landscaping, aligning with world sustainability dreams and local weather adaptation strategies.

5. Future Development Trends

As advances in polymer science, manufacturing techniques, and geotechnical engineering continue, the mechanical strength, durability, and environmental adaptability of slope protection geocell merchandise are predicted to enhance significantly. Future iterations may additionally function improved UV resistance, higher load-bearing capacity, and smarter format elements for less difficult set up and monitoring. From a market perspective, the developing emphasis on sustainable building and the speedy growth of infrastructure improvement global are in all likelihood to speed up the adoption of Geocell systems. With their versatility and eco-friendly attributes, they preserve giant manageable in areas such as inexperienced constructing construction, large-scale ecological restoration, city stormwater management, and transportation engineering, paving the way for progressive functions and broader enterprise acceptance.

6. Summary

BPM Geosynthetics provides customers with comprehensive geocell support: offering customized products covering various materials, heights, and aperture specifications, and developing enhanced geocell for special environments; Provide technical consultation, scheme design, bearing capacity calculation, and slope reinforcement design services based on geological conditions and engineering objectives; The product complies with national and international standards, and strictly controls the quality; Provide construction guidance and long-term after-sales support; And recommend cost-effective solutions based on the budget to ensure stable supply.