How Do You Choose the Right Geocells in Road Construction?

In street construction, the acceptable choice of geocell performs a imperative position in making sure the long-term durability, stability, and overall performance of the roadway. Choosing the proper kind of geocells in road construction no longer solely enhances load distribution and reduces rutting, however additionally improves the basic lifespan of the avenue structure. This information gives complete insights to assist you choose the most appropriate BPM Geocell for your particular avenue building project, thinking about key elements such as soil conditions, site visitors loads, and environmental requirements.

1. Understanding BPM Geocells in Road Construction

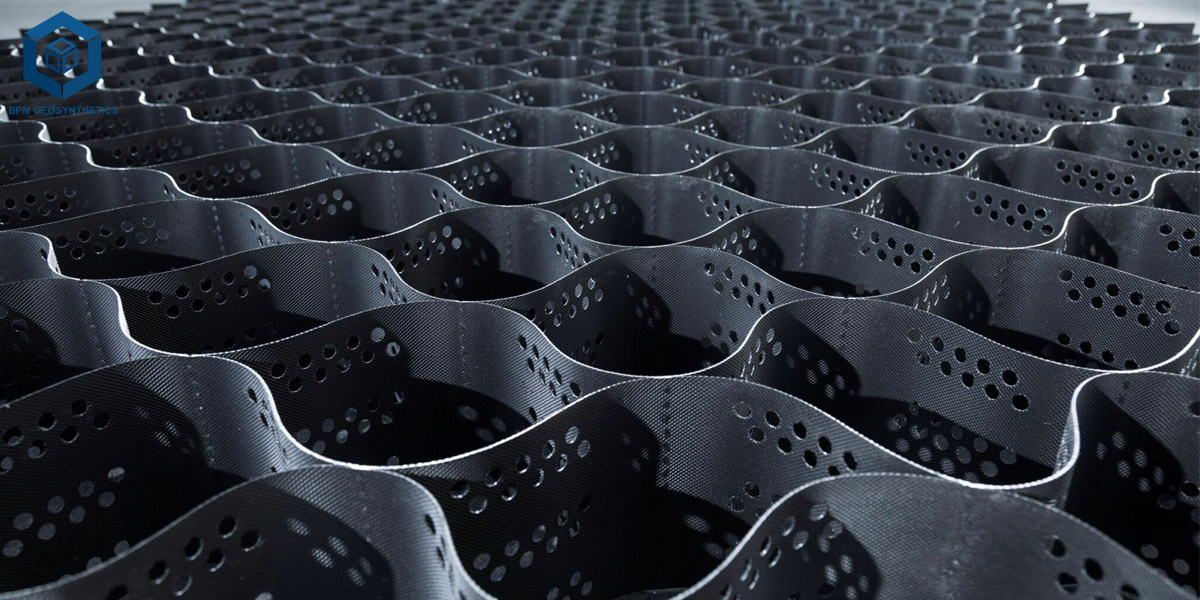

BPM Geocell is a three-dimensional, honeycomb-like cell confinement machine made from high-density polyethylene (HDPE) or different long lasting polymeric materials. These geocell is manufactured through welding or riveting high-strength polymer strips collectively at everyday intervals. When deployed on-site, the strips increase to structure a flexible, interconnected, and third-dimensional mobile structure.

Once expanded, the geocell is usually crammed with regionally accessible substances such as sand, soil, gravel, or beaten stone. This creates a strengthened composite layer with multiplied load distribution and structural integrity. The constrained fill fabric inside the geocell cell types a free-draining, semi-rigid platform that drastically enhances the load-bearing ability of susceptible or unstable soils. Additionally, BPM Geocell structures assist to decrease soil erosion, manage lateral movement, and enhance the standard overall performance and sturdiness of avenue foundations, embankments, and subgrades.

2. Factors to Consider When Choosing Geocells in Road Construction

2.1 Geocells in Road Construction - Load Bearing Requirements

The supposed visitors extent and the kinds of cars that will use the street are essential considerations. For highways with heavy - obligation truck traffic, BPM Geocell hdpe with excessive load - bearing potential are needed. These geocells have to have a excessive dynamic mechanical modulus, which determines their capacity to shop and launch dynamic loading whilst preserving their geometry.

For example, in areas the place there is a excessive quantity of industrial traffic, BPM Tough Cells made from High-density polyethylene (HDPE) are greater appropriate due to their excessive stress and resistance to deformation.

2.2 Geocells in Road Construction - Soil Conditions

The traits of the soil at the building website online play a tremendous position in geocell selection. In tender soil areas such as wetlands or areas with excessive water content, BPM geocell erosion manage can grant the fundamental confinement to stop soil deformation.

For sandy soils, which have excessive fluidity and can purpose giant - scale deformation of the subgrade, it is essential to pick out BPM Geocells with excessive - electricity sheets, high sheet height, and excessive sheet friction to preclude the fluidity of the sand2. In contrast, for particularly steady and company soils in undeniable areas, BPM Geocell with a smaller panel peak can be selected.

2.3 Geocells in Road Construction - Slope and Terrain

The slope of the avenue and the surrounding terrain additionally have an effect on the desire of geocell. For roads with a slope larger than 1:1, it is really helpful to pick geocell driveway with a giant top and a small welding distance, such as the BPM 356 - one hundred - 1.5mm specification2. This kind of geocell can grant higher guide and balance on steep slopes.

For mild slopes much less than 1:2.5, BPM Geocells with a smaller top and a large welding distance, like the BPM 712 - a hundred - 1.5mm specification, can be considered2. They are greater appropriate for such terrains and can additionally meet the necessities of soil confinement and slope protection.

2.4 Geocells in Road Construction - Environmental Factors

Consider the neighborhood local weather and environmental conditions. In areas with excessive temperatures, BPM Geocell have to have suitable warmness resistance to forestall softening and deformation. In bloodless regions, they ought to have low - temperature resistance to keep away from embrittlement.

Additionally, in areas with excessive humidity or terrible drainage, perforated BPM HDPE Geocell is a higher preference as they can enhance water permeability and forestall waterlogging. In corrosive environments such as salt - wealthy soils, geocell slope safety with top notch corrosion resistance, such as those made of HDPE with anti - corrosion additives, need to be selected.

3. Types of BPM Geocells in Road Construction and Their Applications

BPM gives one-of-a-kind kinds of geocell material tailor-made for a variety of geotechnical and infrastructure needs. The 2 major sorts are Perforated and Non-Perforated Geocell, every with awesome structural traits and appropriate software scenarios.

3.1 Perforated Geocells in Road Construction

Perforated Geocell characteristic evenly spaced holes alongside the mobile walls, which play a key position in bettering their performance. These perforations permit for higher lateral drainage, promote soil filtration, and make a contribution to accelerated stress distribution throughout the limited fill material. The graph helps decrease deformation underneath load via dissipating stress extra uniformly all through the structure.

However, the structural integrity of perforated geocells relies upon on each the tensile power of the perforated polymer strips and the sturdiness of the welds or rivets that join them. These geocells are best for purposes the place moisture control, drainage, and soil permeability are critical. They are typically used in roadbeds with high groundwater levels, areas difficulty to well-known rainfall or flooding, and environments the place water accumulation is a concern.

3.2 Non-Perforated Geocells in Road Construction

Non-perforated BPM Geocells are made from thicker, easy polymer sheets barring any holes. These solid-walled geocells are manufactured the usage of ultrasonic welding or mechanical riveting to create a sturdy 3-dimensional mesh structure. The lack of perforations affords brought electricity and makes them distinctly positive in functions that require maximum soil confinement and load-bearing capacity.

These geocell is specially applicable for heavy-duty applications, such as embankment reinforcement, slope stabilization, retaining wall construction, and foundation support in load-intensive infrastructure projects. Their stable partitions assist preserve fill integrity, limit lateral movement, and stop fabric loss, making them an gorgeous desire for difficult terrains or the place drainage is no longer a foremost concern.

4. Quality and Certification of BPM Geocells in Road Construction

When deciding on geocells for road construction, making sure excessive product fine and compliance with diagnosed requirements is essential. The long-term performance, safety, and balance of avenue infrastructure generally rely on the reliability of the geocell system. BPM keeps strict high-quality manage and presents licensed merchandise designed to meet stressful engineering requirements.

4.1 Geocell Material Quality in Road Construction

To assurance most suitable performance, it is necessary to use BPM Geocells made completely from a hundred percent virgin high-density polyethylene (HDPE). Virgin HDPE ensures steady bodily and mechanical properties, together with most reliable tensile strength, flexibility, and long-term durability. Most importantly, it presents greater weld stability—critical for keeping the structural integrity of the geocell community for the duration of set up and beneath load-bearing conditions.

Using geocells made from recycled or low-quality substances can also compromise the system’s integrity. Such substances regularly show off terrible weldability, decreased tensile strength, and decrease resistance to UV radiation and chemical exposure, which can end result in untimely failure below stress or environmental pressure. Therefore, continually request verifiable proof of uncooked fabric composition from the dealer to make sure product reliability.

4.2 Geocells in Road Construction Manufacturer’s Experience and Product Warranty

Selecting a producer with tremendous enterprise journey is equally important. BPM, with over two many years of geosynthetic manufacturing expertise, brings deep expertise of geotechnical engineering and avenue development requirements. A professional producer is extra probably to recognize the nuanced needs of specific soil types, site visitors loads, and climatic conditions.

In addition, a reliable producer ought to provide a product guarantee for BPM Geocells. A assurance no longer solely displays self belief in product high-quality however additionally offers end-users with peace of thought and a security internet towards manufacturing defects or untimely failure. Before purchasing, inquire about the guarantee phrases and after-sales assist available.

4.3 Geocell for Road Construction Certification and Compliance with Standards

To make certain steady product performance, Driveway HDPE geocell should comply with diagnosed worldwide and countrywide great standards, such as ASTM (American Society for Testing and Materials), ISO (International Organization for Standardization), and different applicable geosynthetic trying out protocols.

Certified merchandise bear rigorous fine testing, consisting of assessments of tensile strength, environmental resistance, weld strength, and dimensional stability. These certifications provide clear validation that the geocells meet the structural and environmental necessities imperative for high-performance street construction.

Always request and evaluation the manufacturer’s check reports, fine certificates, and compliance documentation to make sure your assignment is backed through quality-assured materials.

5. Installation and Maintenance of Geocells in Road Construction

5.1 Geocells in Road Construction Installation

The set up of BPM Geocell must be carried out with the aid of educated gurus following the manufacturer's instructions. The geocells must be precise laid out and connected, and the filling substances must be evenly disbursed and compacted. It is additionally necessary to make sure that the set up website online is correct prepared, with no sharp objects or particles that ought to injury the geocells.

5.2 Geocells in Road Construction Maintenance

Regular inspection of the mounted BPM Geocell is critical to make sure their applicable functioning. Check for any signs and symptoms of damage, such as tears or punctures, and restore or change the broken components immediately. Also, display the overall performance of the geocells over time, in particular in areas with excessive site visitors or negative soil conditions, and make any vital changes or reinforcements.

6. Conclusion

Choosing the proper BPM Geocell for road construction entails a thorough comparison of various indispensable factors, along with load-bearing requirements, soil conditions, slope geometry, terrain type, and environmental influences. A well-informed determination process—grounded in a clear appreciation of geocell types, their particular applications, and the significance of product best and certification—can considerably decorate the strength, stability, and lifespan of your avenue infrastructure.

Moreover, appropriate set up and movements protection of BPM Geocells are indispensable to attaining most advantageous overall performance and making sure the long-term protection and reliability of your roadways.

With over 20 years of trip in the geosynthetics industry, BPM Geosynthetics gives high-quality, certified geocell options engineered to meet the worrying desires of cutting-edge avenue building projects. Whether you are reinforcing susceptible subgrades, stabilizing slopes, or enhancing drainage, BPM’s superior geocell structures furnish dependable overall performance backed by using specialist technical support.