60 Mil EPDM Liner

A 60 mil EPDM liner provides superior flexibility, tear resistance, and weather endurance compared to other geomembranes. Its elastic polymer composition allows adaptation to irregular surfaces without stress cracking. The liner’s low permeability and UV stability guarantee long-term performance in both exposed and buried conditions. It is chemically inert, non-toxic, and compatible with a wide pH range, making it ideal for sensitive environmental containment. Installation is straightforward due to its lightweight and foldable nature. Overall, this liner delivers outstanding service life, cost efficiency, and environmental reliability, ensuring lasting protection for civil and industrial projects.

The 60 Mil EPDM Liner is a high-performance artificial rubber membrane particularly engineered for long-term water containment applications. With a thickness of 1.52 mm, this bendy but long lasting liner provides superb resistance to punctures, UV radiation, and severe climate conditions. Manufactured from ethylene propylene diene monomer (EPDM), it stays pliable in temperatures ranging from -40°C to 85°C, making it an best desire for each bloodless and warm climates. Its elasticity lets in it to conform without problems to irregular pond shapes and contours barring cracking or tearing, even after years of use.

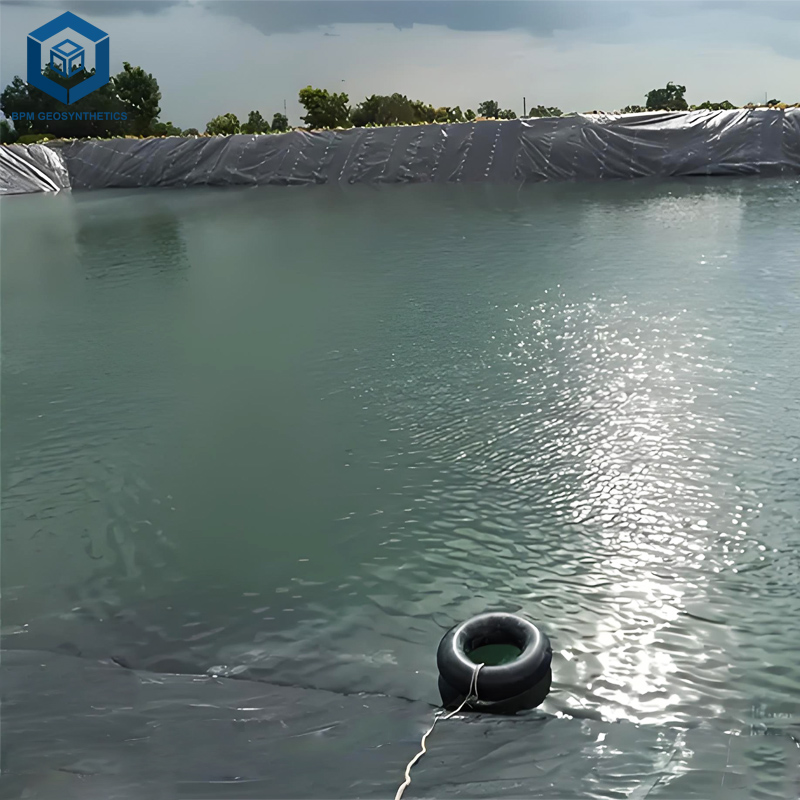

Designed for fish ponds, koi ponds, decorative water features, irrigation reservoirs, and retention basins, the 60 Mil EPDM liner ensures super waterproofing performance and continues structural integrity over time. It is additionally non-toxic and secure for aquatic life, making it a favored alternative for environmentally touchy applications. With a projected lifespan of over 20–30 years and minimal preservation requirements, this liner provides long-term reliability and fee effectivity for residential, commercial, and agricultural water administration projects.

A 60 mil EPDM liner is a high-performance synthetic rubber membrane widely used for water containment, environmental protection, and civil engineering applications. Engineered for flexibility, durability, and chemical resistance, it serves as a crucial barrier in ponds, reservoirs, landfills, and secondary containment systems. This article explores the technical composition, performance characteristics, regulatory standards, and installation best practices of 60 mil EPDM liners, providing a complete understanding aligned with engineering and environmental compliance requirements.

What Is a 60 Mil EPDM Liner?

EPDM (Ethylene Propylene Diene Monomer) is a synthetic elastomer designed for waterproofing and containment. The term “60 mil” refers to the liner’s thickness—equal to 1.52 millimeters—providing enhanced mechanical strength, puncture resistance, and long-term stability compared to thinner alternatives.

Key Physical Properties:

Thickness: 60 mil (1.52 mm)

Tensile Strength: ≥ 1,200 psi (ASTM D412)

Elongation: ≥ 300% (ASTM D412)

Hydraulic Conductivity: < 1×10⁻¹³ cm/s

Temperature Range: -45°C to +85°C

UV Resistance: Excellent, suitable for exposed installations

Engineering Principles

The performance of EPDM liners is governed by polymer elasticity and crosslinked molecular structure, which enables the material to stretch and recover without cracking.

Design principles include:

Elastic Deformation Capacity: Prevents rupture under settlement or differential ground movement.

Low Permeability: Ensures minimal water loss or contaminant migration.

Thermal Stability: Maintains flexibility under fluctuating temperatures.

Chemical Resistance: Resists degradation from fertilizers, acids, and microbial activity.

In landfill or industrial applications, the liner functions as a hydraulic and chemical barrier, reducing environmental contamination risks.

Regulatory Standards and Material Compliance

EPDM liners must comply with international geosynthetic and environmental engineering standards to ensure safety and durability.

Relevant standards include:

ASTM D4637: Standard Specification for EPDM Sheet Used in Single-Ply Roof Membrane.

ASTM D412: Test Method for Rubber Properties—Tensile Strength.

ASTM D570: Water Absorption Properties of Plastics.

EPA 40 CFR Part 264: Liner and leak detection system requirements.

ISO 9001 / ISO 14001: Quality and environmental management certification.

Compliance with these standards ensures that EPDM liners meet performance expectations for hydraulic containment and environmental protection.

Installation and Operational Guidelines

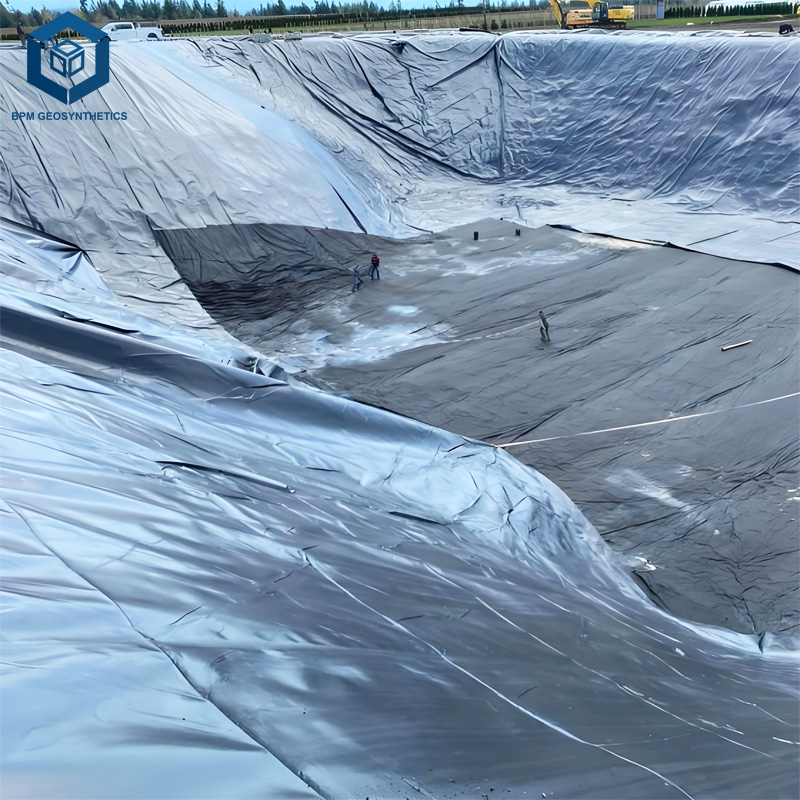

1. Site Preparation

Level and compact the subgrade surface.

Remove sharp stones, roots, and debris that could puncture the liner.

Place a geotextile underlayment where required for cushioning and protection.

2. Liner Deployment

Unroll carefully to prevent creasing.

Allow the material to relax before seaming.

Position panels to minimize overlaps and optimize drainage slope.

3. Seaming and Bonding

Use vulcanized or adhesive seam technology as per ASTM D413 standards.

Conduct seam integrity testing (air channel test or vacuum box method).

4. Quality Assurance

Perform visual inspection for defects.

Conduct leak detection tests before commissioning.

Record installation parameters and test results for compliance verification.

Engineering Applications

A 60 mil EPDM liner is suitable for a broad range of civil, environmental, and industrial applications, including:

Agricultural ponds and reservoirs

Decorative water features and koi ponds

Landfill capping and leachate collection systems

Secondary containment for chemical storage

Mining tailings and process water impoundments

Stormwater retention basins

Performance Advantages

A 60 mil EPDM liner provides superior flexibility, tear resistance, and weather endurance compared to other geomembranes. Its elastic polymer composition allows adaptation to irregular surfaces without stress cracking. The liner’s low permeability and UV stability guarantee long-term performance in both exposed and buried conditions. It is chemically inert, non-toxic, and compatible with a wide pH range, making it ideal for sensitive environmental containment. Installation is straightforward due to its lightweight and foldable nature. Overall, this liner delivers outstanding service life, cost efficiency, and environmental reliability, ensuring lasting protection for civil and industrial projects.

Common Challenges and Mitigation Measures

Thermal Expansion: Allow expansion joints or slack during installation.

Subgrade Movement: Employ geotextile cushioning to prevent puncture.

Chemical Exposure: Verify compatibility through lab testing when used with aggressive substances.

UV Aging: Although resistant, long-term exposed applications should include periodic inspection.

Frequently Asked Questions (FAQ)

1. What does “60 mil” mean in EPDM liners?

It refers to the liner’s thickness—1.52 mm—offering high strength and durability.

2. Can a 60 mil EPDM liner be used in exposed conditions?

Yes, it offers excellent UV resistance and maintains flexibility for decades.

3. How long does a 60 mil EPDM liner last?

Typically 30–50 years, depending on installation quality and environmental exposure.

4. Is EPDM safe for aquatic life?

Yes, EPDM liners are non-toxic and fish-safe when properly cured.

5. How do EPDM liners compare to HDPE liners?

EPDM is more flexible and easier to install, while HDPE offers higher tensile strength but less elasticity.

Safety, Maintenance, and Environmental Considerations

Avoid dragging the liner across rough surfaces.

Conduct periodic inspections for mechanical damage.

Repair punctures using compatible patch materials and vulcanized seam kits.

Follow EPA and ASTM installation guidelines to ensure full environmental compliance.

Conclusion & Professional Call to Action

The 60 mil EPDM liner is a high-performance geomembrane designed for robust containment in both environmental and industrial applications. Its combination of flexibility, impermeability, and chemical resistance ensures superior long-term protection.

If your project requires a durable waterproofing or containment solution, we provide technical support, material selection guidance, and installation consultation based on international engineering standards. Contact our engineering team to discuss how a 60 mil EPDM liner system can enhance your project’s environmental performance, regulatory compliance, and structural integrity.