Non Woven Geo Fabric

Non woven geo fabric is a multifunctional and long lasting fabric designed in particular for a number of civil engineering and development applications. It is made of polypropylene or polyester fibers and has notable filtration, separation, and drainage capabilities. This non woven geo fabric is essential for soil stability, erosion control, and environmental protection.

-High filtration effectivity : Efficaciously approves water to bypass thru whilst holding soil particles and stopping erosion.

-Durability: Resistant to UV rays, chemicals, and biodegradation, making sure long-lasting performance.

-Multifunctional : Suitable for a broad vary of applications, along with avenue construction, panorama beautification, and landfill projects.

-Economically environment friendly : Reduces the demand for extra substances and lowers typical venture costs.

-Easy to set up : Lightweight and flexible, handy for on-site operation and installation.

Non woven geo fabric is a high-performance fabric that performs a integral position in more than a few civil engineering and development projects. This material is made of fibers such as polypropylene or polyester, specifically designed to supply terrific filtration, drainage, and separation performance. Its special non-woven material shape permits water drift to pass by via whilst efficiently maintaining soil particles, making it the quality answer for erosion manage and soil stability.

In functions such as avenue construction, panorama beautification, and landfill management, non woven geo fabrics considerably enhance the lifespan and structural integrity of their aiding materials. Its capability to promote drainage whilst stopping soil erosion is integral for retaining steady floor conditions, specifically in areas inclined to heavy rainfall or floods.

In addition, non woven geo fabrics have wonderful resistance to ultraviolet (UV) radiation, chemicals, and biodegradation, making sure their effectiveness and reliability over a lengthy duration of time. This sturdiness contributes to the ordinary resilience of infrastructure projects, minimizing the want for well-known substitute and maintenance.

This fabric is light-weight and flexible, simplifying on-site dealing with and installation. This ease of use, coupled with its cost-effectiveness - decreasing the want for extra substances - simplifies the building procedure and improves standard task efficiency. Therefore, non woven geo fabrics are the desired desire for engineers and contractors who favor to optimize overall performance whilst keeping finances constraints.

Parameter

ltem | Unit | BTS10 | BTS15 | BTS20 | BTS25 | BTS30 | BTS35 | BTS40 | BTS45 | BTS50 | BTS60 | BTS80 |

Mechanical Properties (MD=Machine Direction Strength/CD=Cross Machine Direction Strength) | ||||||||||||

Weight | g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 |

Weight Variation | % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

Thickness | mm | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3 | 3.3 | 3.6 | 4.1 | 5 |

Width Variation | % | -0.5 | ||||||||||

Break Strength (MD and XMD) | KN/m | 2.5 | 4.5 | 6.5 | 8 | 9.5 | 11 | 12.5 | 14 | 16 | 19 | 25 |

Break Elongation | % | 25-200 | ||||||||||

CBR Burst Strength ≥ | kn | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4 |

Tear Strength(MD and XMD)≥ | Kn | 0.08 | 0.12 | 0.16 | 0.2 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 |

Hydraulic Properties | ||||||||||||

Sieve Size 090 | mm | 0.07-0.02 | ||||||||||

Permeability Coefficient | cm/s | (1.0-9.9)x(10-1~10-3) | ||||||||||

Non Woven Geo Fabric Features

-Excellent filtration performance: Non woven geo fabrics enable water to omit thru whilst efficiently filtering soil particles, making sure appropriate drainage and stopping erosion.

-Enhanced drainage: Its special shape can promote fast water flow, limit the hazard of waterlogging and subsequent soil instability.

-Soil separation: Non woven geo fabric acts as a barrier between one of a kind soil layers, stopping mixing and keeping the integrity of the underlying material.

-Durability: Non woven geo fabrics are made of sturdy artificial fibers that can face up to UV radiation, chemicals, and biodegradation, making sure long-lasting overall performance in a variety of environments.

-Lightweight and flexible: The light-weight nature of this non woven geo fabric makes it convenient to transport and install, permitting for environment friendly dealing with on development sites.

-Economically environment friendly solution: By decreasing the demand for extra substances and labor, Non woven geo fabrics grant an less costly alternative for a number of applications.

-Multi purposeful application: Suitable for a number of purposes, which includes street construction, panorama beautification, erosion control, and landfill management, making it a multifunctional material.

-Environmental sustainability: Many Non woven geo fabrics are made from recycled materials, which make a contribution to eco-friendly constructing practices.

-Easy to install: Its flexibility and light-weight traits facilitate rapid and direct installation, saving mission time and labor costs.

Applications of Non Woven Geo Fabric

-Erosion control: Non woven geo fabric are extensively used to forestall soil erosion in areas inclined to heavy rainfall or robust winds. It stabilizes the slope and embankment, defending the soil from being washed away.

-Drainage Systems : In building projects, Non woven geo fabrics are used in the drainage gadget to filter water and stop soil blockage. It improves the effectivity of drainage pipes and structures by means of permitting water to go with the flow freely whilst stopping soil particles from entering.

-Road construction: In avenue construction, Non woven geo fabrics are used as isolation layers between distinct soil types. It improves the structural integrity of roads by using lowering the hazard of interlayer mixing and movement.

-Landfill Management: Non woven geo fabrics are used for landfill purposes to separate waste from surrounding soil. It helps with leachate management, helps manipulate liquid flow, and protects groundwater.

-Landscape beautification: In panorama beautification projects, Non woven geo fabrics assist manipulate weed increase whilst permitting water and vitamins to penetrate into the soil. It can be used underneath coverings or ornamental stones to hold a smooth and healthful landscape.

-Retaining wall : Non woven geo fabrics need to be utilized at the back of the conserving wall to decorate drainage and limit static water pressure, thereby enhancing the balance and lifespan of the wall structure.

-Construction of Green Roofs: In the inexperienced roof system, Non woven geo fabrics supply a light-weight and high-quality barrier that can aid vegetation whilst permitting for acceptable drainage and ventilation.

-Sports discipline and turf application: Non woven geo fabrics are normally used in the development of sports activities fields to enhance drainage and keep soil integrity, making sure most efficient opposition conditions.

-Mining applications: In mining operations, Non woven geo fabrics are used for floor stabilization and administration of water waft in tailings storage facilities, improving security and environmental protection.

Company Profile

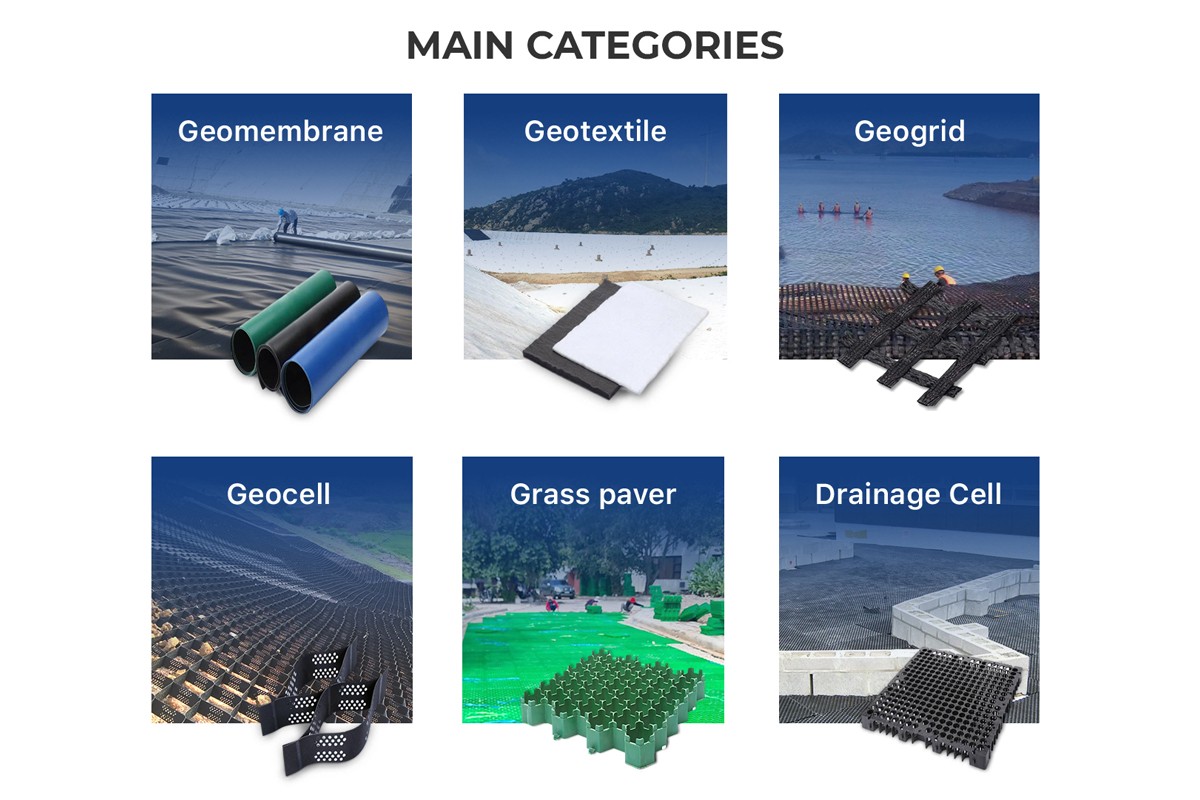

The Best Project Material Co., Ltd. (BPM GEOSYNTHETICS) is a leading manufacturer and exporter of high-quality geosynthetic products, including geomembranes, geotextiles, geogrids, geocells, and geosynthetic clay liners (GCL). Our products, certified by EU CE and GLP, have passed ISO 9001, ISO 14001, and OHSAS 18001 standards, and are recognized for their quality, performance, and durability.

BPM GEOSYNTHETICS has been committed to providing one-stop services for global customers in the research and development, production, sales, and export of geosynthetic materials since its establishment in 2007. The company has 120 senior technical talents specializing in geotechnical materials. The manufacturing factory covers an area of over 36000 square meters and is equipped with industry-leading automated production equipment and professional testing instruments. Product innovation, quality assurance, and customer satisfaction have always been BPM commitment to partners.

We're committed to innovation and quality, offering flexible cooperation and the best solutions for engineering projects worldwide. Our products are utilized in various sectors like aquaculture, erosion control, drainage systems, municipal engineering, mining, and landscaping. We look forward to partnering with you to solve complex challenges with our high-performance geosynthetic products.