What is Geonet And its Applications?

In the world of contemporary civil engineering and environmental management, dependable drainage and soil reinforcement options are greater indispensable than ever. Geonet—a high-performance geosynthetic product—has emerged as a game-changer, providing best strength, flexibility, and environment friendly water float in a compact, light-weight form. From defending landfills and roadways to bettering inexperienced roof structures and holding walls, geonets are remodeling how engineers and builders address drainage, filtration, and stabilization challenges. Discover how this modern answer can bring up your projects, making sure durability, safety, and long-term performance.

1. Introduction to Geonet

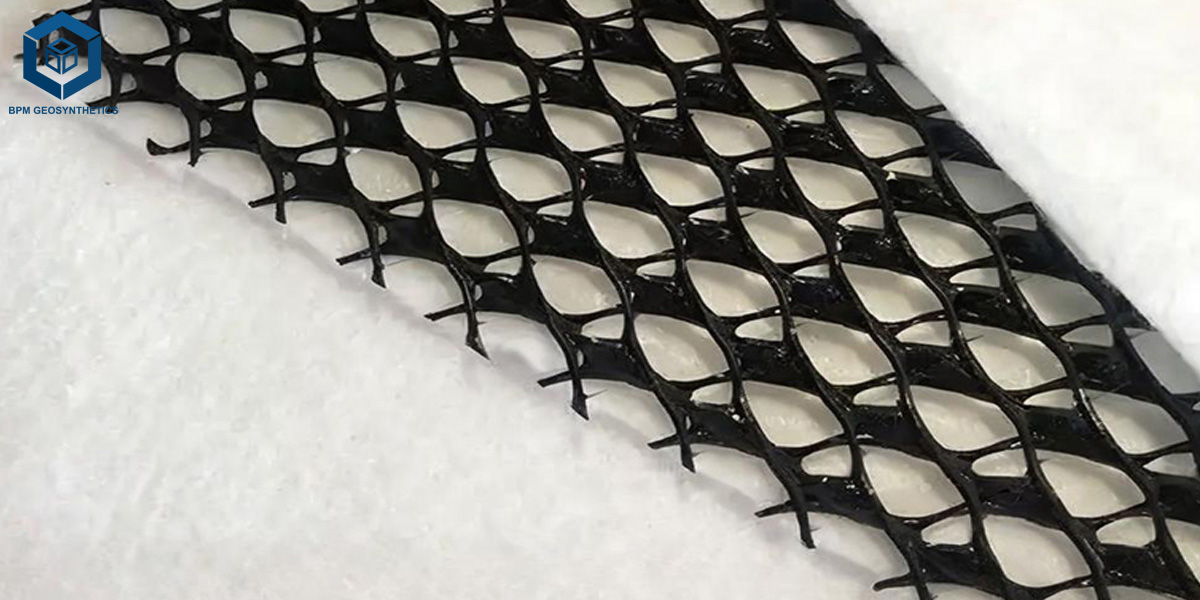

Geonet, quick for geosynthetic net, is a planar community shape composed of interconnected linear factors (such as polymers, metals, or herbal fibers) with in many instances or irregularly spaced apertures. These constructions are designed to possess excessive tensile strength, durability, and permeability, making them integral in quite a number engineering and environmental applications. Developed as phase of the broader area of geosynthetics a self-discipline that makes use of artificial substances to enhance soil and rock engineering performance—Drainage geonet have advanced into a versatile device for fixing complicated challenges in civil engineering, environmental protection, and ecological restoration.

The fundamental composition of geonet commonly consists of high-density polyethylene (HDPE), polypropylene (PP), or polyester (PET), which are chosen for their resistance to chemical corrosion, UV radiation, and mechanical stress. The manufacturing manner entails extruding polymer sheets into skinny films, which are then stretched to shape a network of ribs and apertures. The ensuing shape can range in aperture size, rib thickness, and standard geometry to swimsuit unique venture requirements. For example, uniaxial geonets have elongated apertures oriented in one direction, emphasizing electricity alongside a single axis, while biaxial geonets feature a extra balanced grid structure, presenting electricity in each longitudinal and transverse directions.

2. Geonet Technical Characteristics and Classification

2.1 Geonet Key Technical Properties

- Tensile Strength: Geonet showcase excessive tensile modulus and yield strength, enabling them to stand up to significant masses barring deformation. For instance, HDPE geonet can have tensile strengths ranging from 5 kN/m to over 30 kN/m, relying on the grade.

- Aperture Size and Open Area Ratio: The dimension of the openings (apertures) and the share of open place in the geonet affect its permeability and soil interlock. Larger apertures are appropriate for drainage applications, whilst smaller apertures may also be desired for reinforcement to stop soil particle migration.

- Durability: Polymer-based geonet is designed to withstand degradation from environmental elements such as moisture, temperature fluctuations, and organic activity. Many merchandise endure rigorous trying out to make certain long-term performance, with carrier lives frequently exceeding 50 years in appropriate conditions.

- Flexibility and Conformability: Geonet can conform to irregular surfaces and curved profiles, making them adaptable to complicated website geometries.

2.2 Geonet Classification with the aid of Function and Structure

2.2.1 Reinforcement Geonet

- Purpose: Enhance the mechanical homes of soil or rock hundreds via distributing masses and decreasing deformation.

- Structure: Typically biaxial with a dense grid to maximize interlock with the surrounding soil.

- Materials: High-strength polymers like HDPE or PP, frequently with ribbed surfaces to enhance frictional resistance.

2.2.2 Drainage Geonet

- Purpose: Facilitate the float of water or fuel thru the aircraft of the geonet, regularly used in mixture with geotextiles to structure composite drainage systems.

- Structure: Larger apertures and thicker ribs to create unobstructed glide paths. Some designs consist of built-in geotextile layers for filtration.

- Applications: Subsurface drainage in roads, railways, and landfills; dewatering in protecting walls; and gasoline venting in waste administration facilities.

2.2.3 Protection Geonet

- Purpose: Prevent soil erosion, defend underlying buildings from impact, or act as a cushion layer to distribute factor loads.

- Structure: Thicker, extra inflexible ribs or third-dimensional (3D) constructions to supply bodily protection.

- Example: Plastic geonet used in slope stabilization to anchor vegetation and limit floor runoff erosion.

3. Applications of Geonet in Engineering and Environment

3.1 Geonet for Civil Engineering

3.1.1 Geonet for Road and Railway Construction

- Base Course Reinforcement: Geonet Net is mounted between the subgrade and base path to decrease reflective cracking and enhance load distribution. For example, in bendy pavements, a biaxial geonet can decorate the bearing capability of the subgrade, decreasing the required thickness of mixture layers and reducing development costs.

- Drainage in Pavement Systems: Combined with geotextile, geonet structure environment friendly drainage layers to put off groundwater from the street structure, stopping water-induced harm such as potholes and frost heave.

- Case Study: The Trans-Canada Highway rehabilitation challenge in Alberta utilized geonets to improve vulnerable subgrades, extending the pavement’s provider lifestyles by means of over 20 years while lowering protection fees by means of 30%.

3.1.2 Geonet for Earth Retaining Structures

- Reinforced Soil Walls: Geonet is used as reinforcement layers in routinely stabilized earth (MSE) walls, the place their excessive tensile energy enhances the balance of the backfill soil. The grid shape lets in for sturdy interlock with granular materials, lowering the want for big concrete structures.

- Slope Stabilization: On steep slopes, geonet (often 3D varieties) are anchored to the slope floor to stop shallow soil slips. They can additionally be blended with vegetation to create bioengineered slopes, the place plant roots develop thru the geonet apertures, in addition improving stability.

- Case Study: The building of a 15-meter-high MSE wall in Sydney, Australia, used HDPE geonets with a tensile electricity of 25 kN/m. The layout decreased fabric utilization via 40% in contrast to normal concrete walls, whilst attaining a provider existence of one hundred years.

3.1.3 Geonet for Foundation Engineering

- Soft Soil Improvement: In areas with susceptible or compressible soils, geonets are positioned inside the soil layers to create a strengthened platform. This approach will increase the bearing capability of the soil and reduces settlement. For example, in a landfill task on a tender clay deposit, geonets can forestall differential contract that may want to harm the liner system.

- Basement Waterproofing: Geonets are used as drainage layers at the back of basement partitions to direct groundwater away from the structure, stopping water infiltration and decreasing hydrostatic pressure.

3.2 Environmental Engineering

3.2.1 Geonet for Landfill and Waste Management

- Leachate Collection and Drainage: In municipal strong waste landfills, geonet is mounted above the liner gadget to acquire and transport leachate (contaminated wastewater) to series pipes. The giant apertures and excessive transmissivity of drainage geonets make sure environment friendly flow, stopping the buildup of leachate that should compromise the liner.

- Gas Venting: In biogas-producing landfills, geonets shape phase of the gasoline series system, permitting methane and different gases to migrate thru the grid to extraction wells. This improves security and allows the recuperation of biogas as a renewable strength source.

- Case Study: The New York City Fresh Kills Landfill closure challenge utilized geonets in each leachate and fuel series systems. The geonet-based drainage layers decreased leachate head by way of 80%, notably reducing the chance of liner puncture.

3.2.2 Geonet for Erosion Control and Ecological Restoration

- Vegetation Establishment on Bare Slopes: 3D geonets, regularly mixed with erosion-control mats, grant a substrate for seed germination and root increase on steep or erodible slopes. The geonet retains soil and moisture whilst the vegetation will become established, growing a herbal barrier towards erosion.

- Riparian Buffer Systems: Along rivers and coastlines, geonets are used to stabilize banks and forestall soil loss from wave motion or currents. In tidal zones, they can aid the increase of salt-tolerant plants, bettering ecosystem resilience.

- Case Study: The restoration of a degraded riverbank in the Netherlands used biodegradable geonets made from coir (coconut fiber). Over two years, the geonets decomposed naturally, leaving a steady slope blanketed in native vegetation, which decreased erosion through 95%.

3.2.3 Geonet for Mine Tailings Management

- Drainage and Stabilization: Mine tailings, which are fine-grained waste substances from mineral processing, are frequently tremendously acidic and toxic. Geonets are used to create drainage layers inside tailings impoundments, stopping the accumulation of acidic water and decreasing the hazard of slope failures.

- Capping Systems: Geonets can be included into last covers for mine sites, supplying each drainage and a steady base for vegetation, which helps include contaminants and fix the landscape.

3.3 Geonet for Hydraulic Engineering

3.3.1 Geonet for Dam and Reservoir Construction

- Filter and Drainage Layers: In earth dams, geonets are used as section of filter structures to stop soil particles from migrating whilst permitting water to drain. They are regularly positioned between the dam core and shell substances to keep seepage control.

- Underwater Applications: Geonets with anti-erosion homes can be deployed on the submerged slopes of reservoirs to stop scour from currents or wave action. Their flexibility approves them to conform to underwater topographies besides tremendous set up challenges.

3.3.2 Geonet for Coastal Protection

- Breakwater and Revetment Systems: Geonets are used in aggregate with rock armor or concrete blocks to stabilize coastal structures. The geonet acts as a reinforcement layer, distributing wave forces and decreasing the displacement of protecting materials.

- Sand Dune Stabilization: On beaches, geonets are buried in sand dunes to stop erosion from wind and storm surges. They lure blowing sand, merchandising dune increase and supplying a herbal barrier towards coastal flooding.

3.4 Geonet for Agricultural and Horticultural Applications

- Subsurface Drainage in Agriculture: Geonets are used to drain waterlogged fields, enhancing soil aeration and root growth. In aggregate with geotextiles, they stop soil particles from clogging drainage channels, making sure long-term efficiency.

- Green Roof Systems: In city horticulture, geonets serve as drainage layers in inexperienced roofs, permitting extra water to float away from plant roots whilst keeping moisture for irrigation. They additionally supply a secure base for the developing medium, decreasing the danger of substrate displacement all through heavy rains.

4. Advantages of Geonet Over Traditional Materials

4.1 Geonet Cost-Effectiveness

- Reduced Material Usage: Composite drainage geonet substitute usual substances like gravel or concrete in drainage and reinforcement applications, substantially decreasing transportation and set up costs. For example, a geonet-based drainage layer can be established at 50% of the price of a traditional gravel drain.

- Faster Construction: Geonets are light-weight and convenient to handle, permitting for fast set up in contrast to heavy substances like stone or steel.

4.2 Geonet Environmental Benefits

- Reduced Carbon Footprint: The manufacturing of geonets requires much less power than normal development materials. Additionally, their use in ecological restoration tasks helps mitigate soil erosion and promote biodiversity.

- Waste Reduction: Some geonets are made from recycled polymers, contributing to round economic system initiatives. For instance, recycled HDPE geonets divert plastic waste from landfills whilst supplying purposeful engineering solutions.

4.3 Geonet Technical Superiority

- Longevity and Reliability: Geonet is designed to keep overall performance over decades, even in harsh environments. Their resistance to chemical degradation and organic undertaking ensures steady functionality, in contrast to natural substances that might also decompose.

- Design Flexibility: Geonet can be custom-made in phrases of aperture size, strength, and thickness to meet the unique wishes of every project, supplying a tailor-made answer instead than a one-size-fits-all approach.

5. Geonet Challenges and Future Trends

5.1 Geonet Challenges

- Material Sustainability: While many geonets are made from non-biodegradable polymers, there is developing strain to advance eco-friendly alternatives. Biodegradable geonets made from substances like polylactic acid (PLA) or herbal fibers are in improvement however face challenges in attaining related energy and durability.

- Installation Complexity: In some applications, such as deep subsurface drainage or underwater deployment, appropriate set up of geonets requires specialised gear and expertise, which can enlarge undertaking expenses if no longer managed carefully.

- Regulatory Standards: Variations in regional requirements for geonet checking out and overall performance standards can complicate cloth choice for worldwide projects. Harmonizing requirements would enhance consistency and reliability.

5.2 Geonet Future Trends

- Innovation in Materials: Research is ongoing to enhance hybrid geonets that mix artificial polymers with herbal fibers or nanomaterials to beautify strength, flexibility, and sustainability. For example, carbon-fiber-reinforced geonets ought to provide greater tensile energy in smaller profiles.

- Smart Geonets: Integration of sensors or monitoring structures into geonets is an rising trend. These “smart” geonets may want to grant real-time information on parameters like soil moisture, temperature, or stress, enabling proactive protection and early detection of structural issues.

- Circular Economy Practices: The enterprise is shifting towards accelerated use of recycled substances and designing geonets for less complicated recycling at the stop of their provider life. Some producers now provide take-back applications to recycle ancient geonets into new products.

- Digital Design Tools: Advanced modeling software, such as finite component evaluation (FEA), is being used to optimize geonet placement and design, making sure most effectivity and cost-effectiveness in projects.

6. Conclusion

Geonet have revolutionized the way engineers strategy soil stabilization, drainage, and environmental protection. Their versatility, durability, and cost-effectiveness make them crucial in a vast vary of applications, from street development to ecological restoration. As the enterprise continues to prioritize sustainability and innovation, geonets are poised to play an even large function in future infrastructure and environmental projects. By addressing challenges such as fabric sustainability and embracing new technologies, geonets will continue to be a cornerstone of modern-day geosynthetic engineering, using ahead options that are each technically strong and environmentally responsible.

For magnificent geonet backed by means of technical information and international mission experience, BPM Geosynthetics is your relied on partner.