Drainage Cell: Efficient Water Management for Sustainable Construction

Drainage Cell: The Key to Effective Subsurface Water Management in Modern Construction

In modern construction and landscaping, drainage cells have emerged as a crucial component for efficient water management, especially in green roofs, podium gardens, basements, and civil engineering projects. Designed to create an effective subsoil drainage system, drainage cells help control excess water, protect waterproofing layers, and promote sustainable construction practices.

This article explores the technical features, market trends, applications, and manufacturing insights of drainage cells, offering valuable information for international B2B buyers seeking reliable and durable drainage solutions.

Global Market Overview and Growth Potential

The global drainage system market has been growing rapidly, driven by urbanization, stricter building regulations, and the demand for sustainable green infrastructure. Within this market, drainage cells have become a preferred solution due to their lightweight structure, high compressive strength, and long-term durability.

According to market research, the global demand for drainage cells is projected to reach USD 700 million by 2032, with an annual growth rate exceeding 5.5%. The Asia-Pacific region—particularly China, India, and Southeast Asia—leads the market due to increased infrastructure investments and green building initiatives. Meanwhile, Europe and North America continue to adopt drainage cells in roof gardens, sports fields, and retaining wall systems.

What Is a Drainage Cell?

A drainage cell is a high-strength modular interlocking panel made primarily from high-density polyethylene (HDPE) or polypropylene (PP). It is designed to form a continuous void space that enables rapid water flow beneath the surface, preventing hydrostatic pressure buildup and ensuring proper water discharge.

Drainage cells are widely used in:

Roof gardens and green roofs to manage rainwater and protect the waterproofing membrane.

Podium landscapes and planter boxes for efficient subsoil drainage.

Basement walls and retaining structures to prevent water seepage.

Sports fields, driveways, and civil works to maintain soil stability and prevent flooding.

Technical Features and Performance Advantages

1. High Load-Bearing Capacity

Modern drainage cells are engineered to withstand heavy loads and long-term compression. High-quality HDPE materials offer excellent structural integrity, ensuring performance under paving, soil, or landscaping layers.

2. Lightweight and Easy Installation

Due to their modular design and lightweight nature, drainage cells can be quickly installed without heavy machinery. The interlocking panels allow easy customization for different project sizes and layouts.

3. Efficient Water Flow and Root Aeration

The void structure of drainage cells promotes rapid water drainage, reducing the risk of waterlogging. At the same time, it allows root aeration, which is essential for plant health in green roofs and landscaped areas.

4. Protection for Waterproof Membranes

By creating a separation layer between soil and waterproofing, drainage cells prevent root intrusion, mechanical damage, and excessive moisture retention—significantly extending the lifespan of waterproof systems.

5. Chemical and Environmental Resistance

HDPE-based drainage cells are resistant to chemicals, acids, and microbial degradation, making them ideal for use in diverse climates and soil conditions. Additionally, they are recyclable, supporting environmentally sustainable construction practices.

Applications of Drainage Cells in Modern Infrastructure

1. Roof Gardens and Podium Landscapes

Drainage cells are a fundamental component in roof garden systems. They maintain an optimal balance between water retention and discharge, ensuring healthy plant growth while preventing structural water accumulation.

2. Basement and Retaining Walls

Installed along waterproof membranes, drainage cells facilitate continuous water flow away from the structure, preventing pressure buildup and reducing long-term maintenance costs.

3. Sports Grounds and Parking Areas

In sports fields, drainage cells provide a sub-surface drainage network that helps maintain playable conditions after heavy rain. In parking areas, they prevent surface cracking caused by trapped moisture.

4. Civil Engineering and Infrastructure Projects

In highways, tunnels, and airports, drainage cells play a vital role in stabilizing subgrade layers and managing stormwater runoff efficiently.

Manufacturing Process and Quality Control

Producing high-quality drainage cells involves precision molding and strict material control:

Material Selection: Virgin HDPE or PP granules are selected for consistent strength and durability.

Injection Molding: The materials are molded into modular panels with precise interlocking edges.

Quality Testing: Each batch is tested for compressive strength, chemical resistance, and water flow rate.

Packaging and Shipping: The panels are stacked and packed compactly to reduce logistics costs for bulk orders.

B2B buyers should ensure that suppliers comply with ISO and ASTM standards, as these guarantee performance and longevity in real-world applications.

Market Trends: Sustainability and Green Infrastructure

With growing environmental awareness, the construction industry is shifting toward sustainable water management systems. Green roofs, smart cities, and eco-architecture projects increasingly rely on drainage cells to manage stormwater and reduce the urban heat island effect.

Manufacturers are also innovating with recycled HDPE materials, improving both sustainability and cost-efficiency. The integration of IoT-based drainage monitoring systems is an emerging trend, especially in large-scale infrastructure and landscaping projects.

How to Choose the Right Drainage Cell

When sourcing drainage cells for your project or distribution line, consider the following:

Material Type: HDPE offers superior durability and resistance.

Compressive Strength: Suitable for intended load conditions.

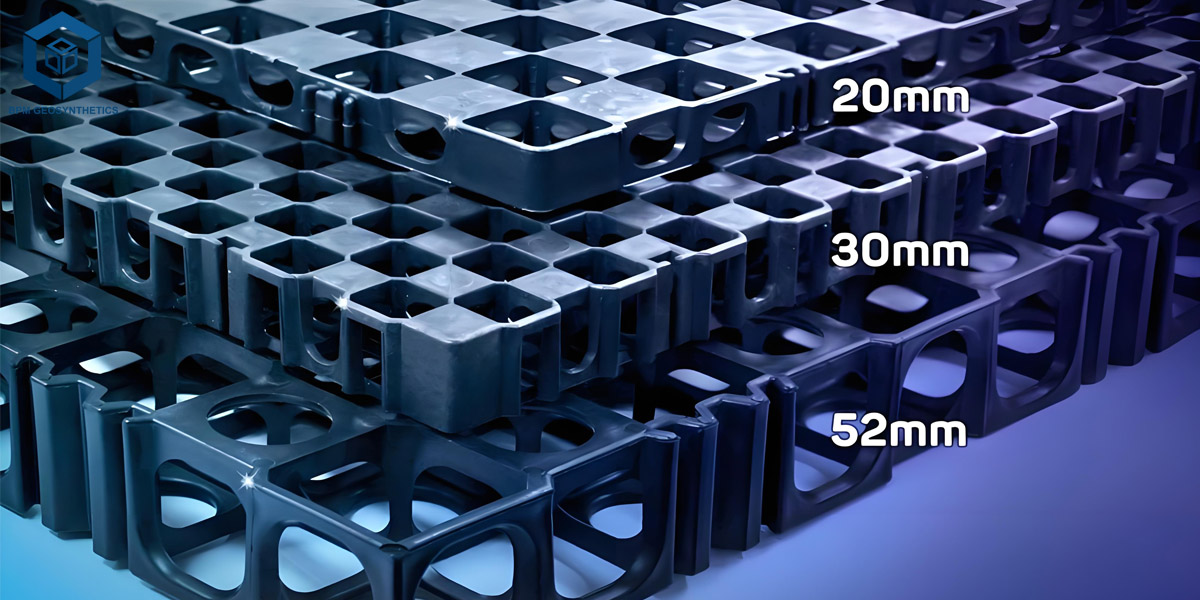

Thickness and Void Depth: Affects drainage capacity and installation height.

Interlocking Design: Simplifies installation and ensures structural stability.

Testing Certification: Compliance with international drainage performance standards.

Frequently Asked Questions (FAQ)

Q1: What is the lifespan of a drainage cell?

A1: High-quality HDPE drainage cells typically last over 20 years, depending on installation conditions and load requirements.

Q2: Can drainage cells be used with waterproof membranes?

A2: Yes. Drainage cells are designed to protect waterproof layers while ensuring efficient sub-surface water discharge.

Q3: Are drainage cells suitable for vertical applications like retaining walls?

A3: Absolutely. Their lightweight and modular structure make them ideal for both horizontal and vertical drainage systems.

Q4: What is the standard thickness of a drainage cell?

A4: The most common thicknesses range from 20mm to 50mm, depending on project specifications.

Conclusion: Smart Drainage Solutions for Modern Architecture

In an era of sustainable and efficient construction, drainage cells play an essential role in preventing water-related structural issues, supporting vegetation growth, and extending the life of waterproofing systems.

For B2B buyers, partnering with a reliable drainage cell manufacturer ensures not only consistent product quality but also long-term project success.

Looking for customized drainage solutions or bulk supply options?

We provide professional manufacturing and export support tailored to your project specifications. Contact us today to discuss your drainage cell requirements, technical drawings, or OEM customization needs.