What is Geomembrana LLDPE ?

Geomembrana LLDPE (Linear Low-Density Polyethylene Geomembrana) is a flexible, durable, and chemically resistant geomembrane liner extensively used in civil engineering, environmental protection, and water containment projects. Known for its most desirable elongation, puncture resistance, and adaptability to uneven surfaces, LLDPE geomembrane presents an high quality barrier towards beverages and gases. It is typically utilized in ponds, landfills, mining, and agricultural reservoirs the place long-term waterproofing and containment are essential.

1. What is Geomembrane LLDPE ?

1.1 Introduction to Geomembrana LLDPE

LLDPE (Linear Low-Density Polyethylene) Geomembrane is a synthetic membrane liner crafted from high-quality polyethylene resins, serving as an impermeable barrier in various engineering and environmental projects. As part of the broader family of geosynthetic materials, which includes geotextiles, geogrids, and geocomposites, geomembranes are specifically engineered to control fluid or gas migration in structures. The unique molecular structure of LLDPE—characterized by its linear arrangement with short, controlled branches—grants it a balanced combination of flexibility, durability, and chemical resistance, distinguishing it from other geomembrane types like HDPE (High-Density Polyethylene) or PVC (Polyvinyl Chloride). Typically available in thicknesses ranging from 0.1 mm to 3.0 mm, LLDPE Geomembrana is manufactured into rolls of varying widths (e.g., 1–10 meters) and lengths (e.g., 50–200 meters), allowing for customized installation across diverse projects.

1.2 Geomembrana LLDPE Material Composition and Structure

The production process involves polymerizing ethylene with alpha-olefins, resulting in a material that exhibits higher tensile strength and puncture resistance compared to conventional LDPE (Low-Density Polyethylene). This molecular design enables the membrane to maintain flexibility under low temperatures while resisting cracking and deformation under mechanical stress.

1.3 Industry Standards and Quality Assurance

According to international standards such as ASTM and GRI-GM13, geomembrane sheet LLDPE undergoes rigorous testing for essential properties like tensile strength, elongation, and environmental stress cracking resistance. These tests ensure that the product performs reliably under demanding environmental conditions, such as exposure to UV radiation, temperature fluctuations, and chemical agents.

1.4 Geomembrana LLDPE Applications and Performance

Originally developed for containment applications in waste management and mining, LLDPE geomembrane liner has evolved to serve a wide range of modern infrastructure needs, including aquaculture ponds, water conservation projects, landfill liners, and agricultural reservoirs. Its adaptability and cost-effectiveness make it an ideal choice for long-term waterproofing and environmental protection.

1.5 Geomembrana LLDPE Manufacturers and Sustainable Benefits

Brands like BPM Geosynthetics specialize in producing Geomembrana pond liner that meets international benchmarks, offering products tailored to specific project requirements such as fishpond liners, canal linings, or landfill covers. As a sustainable alternative to traditional construction materials like clay or concrete, LLDPE liner sheet help prevent contamination, conserve water resources, and support eco-friendly engineering solutions.

2. Scope of Applications — Geomembrana LLDPE

LLDPE Geomembrane is renowned for their versatility across multiple industries, driven by their impermeability, flexibility, and resistance to environmental stressors. These geomembrane serve as essential barriers in projects that require long-term containment and protection against chemical, mechanical, and UV degradation.

2.1 Environmental and Industrial Engineering Applications

In environmental engineering, LLDPE membrane sheet is widely used in landfill liner and caps to prevent leachate from contaminating groundwater. They are also integral to tailings storage facilities in mining operations, effectively containing hazardous waste materials. The impermeable liner material’s excellent chemical and UV resistance makes it ideal for industrial containment systems, including fuel storage tanks, wastewater treatment ponds, and secondary containment units.

Furthermore, in water resource management, geomembrane 1.5 mm is commonly applied in irrigation canals, reservoirs, and decorative water features such as artificial lakes, where it minimizes seepage and enhances water conservation efficiency.

2.2 Agricultural, Aquaculture, and Infrastructure Applications

In agriculture and aquaculture, Geomembrana plastic liner has become indispensable for constructing durable and hygienic pond liners. For example, in fish and shrimp farming, the liner creates a controlled aquatic environment that prevents water loss and shields aquatic stock from soil-borne contaminants. Its flexibility allows easy installation in irregularly shaped ponds—common across aquaculture regions like Southeast Asia and Africa.

Beyond water containment, LLDPE geomembrane pond is also used in infrastructure development, including tunnel waterproofing, roadbed protection, and erosion control on slopes. With the global membrane waterproofing market projected to grow by 13.75% annually, reaching nearly 80 billion CNY by 2025, the demand for LLDPE variants is expected to rise sharply, particularly in emerging economies prioritizing sustainable infrastructure solutions.

3. Key Characteristics and Advantages — Geomembrana LLDPE

Geo membrane LLDPE boast a suite of exceptional properties that make them a preferred choice for various containment and waterproofing applications. Their unique molecular structure provides an optimal balance between flexibility, strength, and chemical resistance—qualities essential for modern environmental and civil engineering projects.

3.1 Exceptional Flexibility and Mechanical Strength

One of the most notable advantages of polyethylene geomembrane is their high flexibility and elongation at break, often exceeding 700%. This outstanding elasticity enables the material to tolerate ground settlement, seismic movement, and structural deformation without cracking or tearing. Such mechanical resilience ensures long-term liner stability, even under challenging installation conditions or on irregular subgrades.

3.2 Superior Chemical and Environmental Resistance

LLDPE liner geomembrane demonstrate excellent resistance to a wide range of chemicals, including acids, alkalis, oils, and saline solutions. This property makes them ideal for use in mining operations, industrial containment, and chemical storage facilities. Their low permeability—with hydraulic conductivity as low as 1×10⁻¹⁷ cm/s—creates an effective barrier against both liquids and gases, providing reliable containment performance in demanding environments.

3.3 Easy Installation and Seam Integrity

Another significant advantage of smooth geomembrane LLDPE is its ease of installation and strong seam bonding. These liners can be welded using thermal fusion, extrusion, or solvent-based methods, forming continuous, watertight seams that maintain the material’s impermeability. This feature is particularly valuable for large-scale applications such as landfills, aquaculture ponds, and reservoirs, where seamless coverage is critical for preventing leakage and maintaining system integrity.

3.4 UV Resistance and Long-Term Durability

When stabilized with carbon black and antioxidant additives, LLDPE geomembrane liner achieve excellent UV resistance and weather durability, extending their service life beyond 20 years in exposed outdoor environments. For instance, BPM Geosynthetics’ LLDPE impermeable geomembrane products are specially formulated with anti-aging stabilizers, ensuring reliable performance in aquaculture ponds, irrigation canals, and landfill covers subject to prolonged sunlight and temperature variations.

3.5 Cost Efficiency and Sustainability

By combining mechanical strength, chemical resistance, and installation ease, pond liner LLDPE delivers substantial cost savings through reduced maintenance, faster deployment, and extended service life. Furthermore, its environmentally friendly composition and recyclability support sustainable construction practices, making it a responsible choice for eco-conscious engineering projects.

4. Role and Effectiveness in Fish Farming Projects — Geomembrana LLDPE

In fish farming projects, pond liner 500 micron functions as a protective and impermeable liner that establishes a controlled aquatic environment. Its contribution extends beyond simple water containment—it enhances productivity, biosecurity, and sustainability, making it an indispensable material for modern aquaculture systems.

4.1 Water Conservation and Seepage Prevention

One of the primary roles of LLDPE sheet for farm pond is to prevent water seepage into the ground, thereby conserving valuable water resources. This is particularly important in arid regions or porous soil conditions, where water loss can significantly affect productivity. By forming an impermeable barrier, LLDPE liners can reduce water usage by up to 50% compared to unlined ponds, lowering overall operational costs and ensuring stable pond water levels.

4.2 Biosecurity and Disease Prevention

LLDPE geomembrana 40 mils create a sealed separation between water and soil, effectively isolating aquatic species from soil-borne pathogens, pollutants, and predators. This reduces the risk of disease outbreaks and improves fish and shrimp survival rates. In shrimp farming, for instance, the smooth and non-porous surface of the membrane liner facilitates easy cleaning and sludge removal, preventing the buildup of organic matter that could deteriorate water quality.

4.3 Chemical Compatibility and Water Quality Stability

The durability and chemical inertness of 30 mil geomembrane liner make it compatible with aquaculture-related inputs such as fertilizers, antibiotics, and feed additives. It does not react with or leach harmful substances into the pond water, ensuring the stability of key parameters like pH levels, dissolved oxygen, and salinity. Maintaining these optimal water conditions is critical for healthy fish growth and efficient feed conversion.

4.4 Durability and Performance in Intensive Farming

Brands such as BPM Geosynthetics design LLDPE geomembrana 1mm specifically for aquaculture applications, incorporating non-toxic formulations, reinforced seams, and enhanced puncture resistance to withstand dynamic loads from equipment or livestock movement. Field results from BPM projects have demonstrated zero seepage, long-term durability, and significant maintenance cost reductions, confirming the liner’s reliability in intensive aquaculture operations.

4.5 Environmental Protection and Sustainability

Beyond operational benefits, impermeable geomembrane liner LLDPE plays a crucial role in environmental sustainability. It prevents groundwater contamination by containing organic waste and nutrient-rich effluents within the pond system. This containment supports eco-friendly aquaculture practices, ensures compliance with environmental regulations, and helps farms achieve sustainability certifications.

5. BPM Geosynthetics Brand Overview

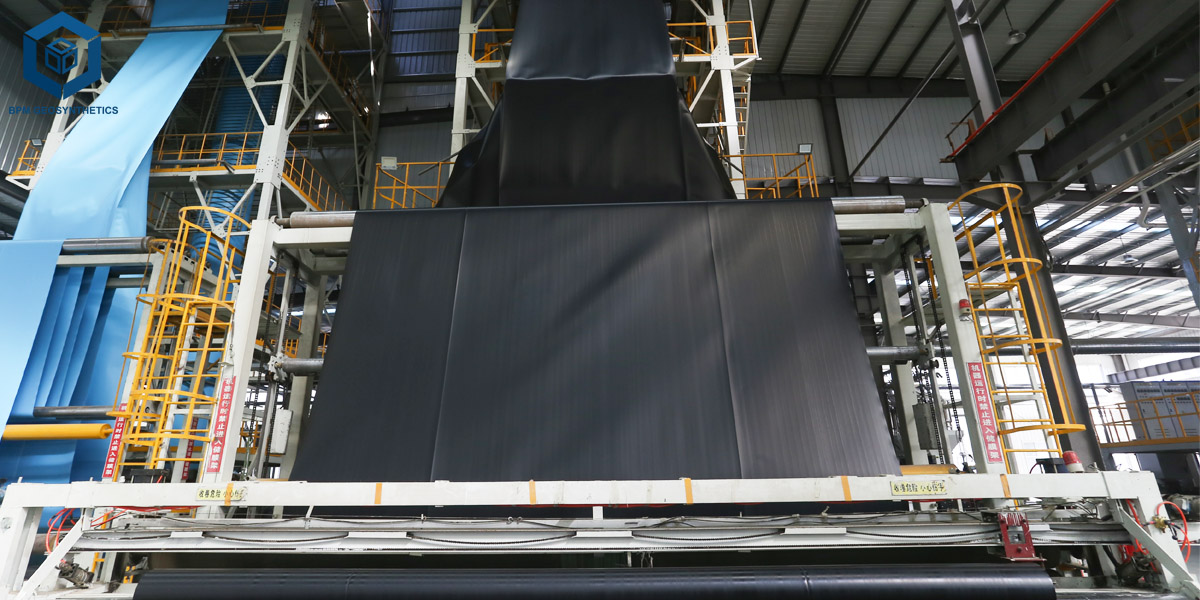

BPM Geosynthetics has established itself as a leading manufacturer of high-quality geomembranes, including LLDPE variants tailored for global engineering and aquaculture projects. The company’s products adhere to international standards such as ASTM GRI-GM13 and are certified by ISO, CE, BV, and other regulatory bodies, ensuring consistent performance and safety . BPM’s LLDPE geomembrane is available in thicknesses from 0.1 mm to 3.0 mm, with customizable widths (up to 10 meters) and colors (e.g., black, blue, green, white), allowing clients to optimize specifications for projects like fishpond liners or landfill caps .. The brand emphasizes quality control through every production stage, from raw material selection—using virgin HDPE/LLDPE resins—to advanced manufacturing processes that enhance properties like tensile strength and UV resistance .

A key strength of BPM Geosynthetics is its comprehensive service model, which includes technical support, on-site installation guidance, and customized solutions .. For aquaculture clients, the company provides tailored geomembrane systems that address common challenges, such as uneven terrain or corrosive water conditions, backed by warranties of up to 10 years. Testimonials from users in sectors like mining and fish farming underscore the liners’ effectiveness in preventing seepage and reducing long-term costs . By integrating innovation with sustainability, BPM Geosynthetics contributes to the growth of the geomembrane market, which is projected to expand rapidly under initiatives like China’s "Two News and One Heavy" strategy, focusing on infrastructure and environmental protection.

Conclusion

Geomembrana LLDPE stands as a necessary innovation in geosynthetic engineering, combining flexibility, chemical resistance, and impermeability to supply dependable containment options throughout environmental, industrial, and aquaculture applications. Its durability, adaptability, and eco-friendly overall performance make it fundamental for contemporary infrastructure and sustainable development. As international center of attention on water conservation and air pollution manipulate intensifies, LLDPE geomembranes will proceed to play a key function in making sure long-term challenge effectivity and environmental protection.

For extremely good and licensed LLDPE geomembranes, The Best Project Material Co., Ltd.(BPM Geosynthetics)is a relied on producer providing superior merchandise tailor-made to international venture needs. With over 36,000 m² of manufacturing services and global certifications, BPM Geosynthetics promises durable, efficient, and customizable geomembrane options — your dependable associate in sustainable engineering.