Gravel Driveway Fabric

Gravel driveway fabric is engineered to decorate floor stability, enhance drainage, and forestall gravel migration. Made from long lasting woven or nonwoven geotextile, it’s perfect for residential and business driveways, parking areas, and rural get admission to roads.

- Excellent Stabilization: Prevents mixing of gravel and subsoil, retaining a steady base.

- Available Weight Range: 100g/m² to 1000g/m²

- Roll Widths: 1m to 7m

- Roll Lengths: 10m to 200m

- Colors: Black (standard), White, Gray (customizable)

- Material Options: PP or PET, woven or nonwoven

- UV Treatment: Optional UV stabilization for long-term out of doors publicity

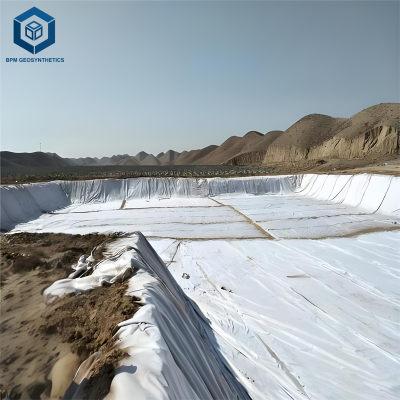

BPM Geosynthetics provides high-performance gravel driveway fabric specially engineered to enhance the strength, longevity, and average overall performance of gravel-based driveways and unpaved get right of entry to roads. Designed as a long lasting gravel driveway fabric solution, this cloth serves as a quintessential barrier between the underlying soil (subgrade) and the gravel layer above. By growing a secure separation layer, it prevents the intermixing of materials, which is a frequent purpose of floor deformation, sinking, and rutting underneath vehicular loads.

In addition to its separation function, the gravel driveway fabric additionally presents incredible filtration capabilities. It approves rainwater and runoff to drain correctly via the gravel and into the soil, whilst concurrently keeping quality soil particles. This helps forestall waterlogging, erosion, and frost heave—common troubles that limit the practical lifespan of gravel surfaces.

By reinforcing the shape of the driveway and minimizing the want for common gravel replenishment or floor repairs, BPM’s geotextile material reduces long-term upkeep prices and labor requirements. Whether used in residential driveways, farm roads, or rural get right of entry to paths, this gravel driveway fabric appreciably improves floor stability, load-bearing capacity, and resilience in all climate conditions. Engineered from UV-stabilized polypropylene or polyester materials, it additionally performs reliably in harsh out of doors environments, making it a least expensive and eco-friendly preference for gravel floor reinforcement.

Gravel Driveway Fabric Technical Specifications

Property | Options |

Weight | 100g/m² – 1000g/m² |

Roll Width | 1m – 7m |

Roll Length | 10m – 200m |

Color Options | Black (standard), White, Gray (customizable) |

Tensile Strength | Up to 80 kN/m (depending on fabric type) |

Permeability | Tailored to project drainage needs |

UV Resistance | Optional UV treatment for extended outdoor use |

1. Gravel Driveway Fabric Product Materials

BPM’s gravel driveway fabric are manufactured the usage of exquisite uncooked substances and superior production techniques, making sure first-rate sturdiness and overall performance below stressful conditions. We provide two foremost kinds of geotextile material to go well with unique driveway applications:

1.1 Woven Geotextile

- Constructed by using weaving polypropylene or polyester yarns in a precise, crisscross pattern.

- Offers high tensile strength and amazing load distribution, making it perfect for reinforcement and subgrade stabilization.

- Best appropriate for functions that require long-term strength, such as driveways uncovered to heavy automobile visitors or soft, unstable ground.

- Provides reasonable water flow, making it extra appropriate for areas the place electricity is prioritized over drainage.

1.2 Nonwoven Geotextile

- Manufactured the usage of a needle-punched or heat-bonded manner that types a fabric-like mat.

- Features excellent permeability, permitting water to pass by thru whilst trapping soil particles, making it perfect for filtration and drainage functions.

- Particularly wonderful in stopping waterlogging and merchandising subsoil drainage in driveways constructed on moist or clay-rich terrain.

- More bendy and less difficult to conform to uneven or irregular surfaces in the course of installation.

1.3 Materials Used: Polypropylene (PP) or Polyester (PET)

- Both PP and PET provide sturdy resistance to organic degradation, chemicals, and mildew, making sure long-term overall performance in outside environments.

- Polypropylene is lightweight, chemically inert, and extra cost-effective, many times used for frequent driveway and landscaping applications.

- Polyester provides barely greater elongation and UV stability, making it appropriate for greater traumatic or uncovered installations.

- All fabric can be UV-stabilized upon request to beautify resistance to daylight and prolong provider lifestyles in uncovered purposes except gravel cover.

2. Gravel Driveway Fabric Key Functions

2.1 Separation

Gravel driveway fabric serves as an fine barrier between the gravel floor and the underlying gentle or unstable subsoil. By stopping the two layers from mixing, the material keeps the structural integrity of the driveway over time. Without separation, gravel can sink into the subgrade, main to floor deformation, unevenness, and regular maintenance. This separation feature is mainly vital in areas with clay soils, moisture fluctuations, or heavy traffic.

2.2 Reinforcement

The gravel driveway fabric enhances the load-bearing ability of the driveway through reinforcing vulnerable or free soils underneath the gravel. It distributes the weight of automobiles evenly throughout a broader area, which reduces stress on the subgrade. As a result, the formation of ruts, depressions, and potholes is minimized, even beneath repeated or heavy loading. This makes the driveway extra long lasting and appropriate for each mild residential use and heavier functions like RVs or farm machinery.

2.3 Filtration

Designed with a permeable structure, the gravel driveway fabric approves water to ignore freely via whilst conserving first-class soil particles. This filtration feature promotes ideal drainage, stopping water buildup or pooling on the surface. By managing subsurface water flow, it helps keep away from problems like frost heave, soil saturation, and fabric washout, all of which can shorten the existence of a driveway if no longer right addressed.

2.4 Erosion Control

In sloped areas or areas susceptible to water runoff, the gravel driveway fabric presents gorgeous safety towards erosion. It stabilizes the floor and helps keep each gravel and soil in place, decreasing the chance of washout for the duration of heavy rains. By anchoring the base layer and enhancing floor stability, the cloth helps preserve the integrity of the driveway’s shape over time, mainly in difficult terrain.

2.5 Weed Barrier

Acting as a bodily barrier under the gravel, the material inhibits weed increase through blockading daylight and stopping seeds from attaining the soil. This herbal weed manipulate reduces the want for herbicides or conventional guide removal, maintaining the driveway searching easy and well-maintained. It additionally helps forestall roots from pushing thru and disrupting the gravel layer, similarly maintaining floor stability.

3. Why Choose BPM Geosynthetics?

BPM Geosynthetics is a relied on international producer of high-performance geosynthetic materials, dedicated to turning in dependable quality, cost effective solutions, and exceptional consumer support. Here’s why engineers, contractors, and distributors global pick out BPM:

3.1 ISO-Certified Production

- All BPM manufacturing services function below ISO 9001 and ISO 14001 certifications, making sure compliance with the easiest worldwide requirements for first-rate administration and environmental responsibility.

- Each roll of geotextile cloth undergoes rigorous in-house testing for strength, weight, permeability, and sturdiness to meet each task specs and enterprise benchmarks.

- Quality manage is embedded into each stage of production—from uncooked cloth inspection to ultimate packaging—ensuring steady product performance.

3.2 Factory Direct Supply

- As a vertically built-in manufacturer, BPM presents factory-direct pricing with no middlemen, handing over robust value blessings to international clients.

- Products are shipped without delay from our facility to your site, saving each time and money.

- With bendy manufacturing capability and a broad vary of inventory specifications, BPM can rapidly fulfill each small and large-volume orders with speedy lead times.

3.3 Extensive International Experience

- BPM has exported geosynthetics to over a hundred and twenty countries throughout North America, South America, Europe, Southeast Asia, the Middle East, Africa, and Oceania.

- Our merchandise have been effectively used in thousands of engineering projects, along with avenue construction, drainage systems, mining, agriculture, and environmental protection.

- With in-depth know-how of global requirements and regional undertaking requirements, BPM is well-positioned to help numerous infrastructure and civil engineering needs.

3.4 Expert Technical Support

- BPM offers dedicated pre-sale and after-sale technical services, which includes fabric selection, sketch recommendations, and set up guidance.

- Our skilled engineering group is handy to aid with custom specifications, performance calculations, and application-specific challenges.

- Whether you want assist with driveway material layout, overlap design, or building methods, BPM provides responsive, multilingual assist to make certain your project’s success.

4. Gravel Driveway Fabric Typical Applications

BPM’s gravel driveway fabric is versatile and engineered to operate in a huge vary of residential, agricultural, and business applications. Below are some of the most frequent and fantastic uses:

4.1 Gravel and Crushed Stone Driveways

- Provides a steady basis for gravel driveways through keeping apart the gravel layer from the subsoil.

- Prevents gravel loss and rut formation, extending the lifespan of the driveway.

- Ideal for each new installations and improvements to present driveways on clay, sand, or gentle soil.

4.2 Parking Pads and RV Access Roads

- Supports heavy hundreds such as parked vehicles, trailers, and leisure vehicles.

- Distributes weight evenly to stop floor sinking or deformation.

- Improves floor balance and reduces long-term protection for automobile get entry to zones.

4.3 Farm Roads and Private Lanes

- Enhances rural and agricultural get right of entry to routes by using reinforcing vulnerable ground.

- Prevents mud buildup and rutting brought about through tractors, utility vehicles, and heavy farm equipment.

- Ensures year-round accessibility, even at some stage in moist or freeze-thaw conditions.

4.4 Pathways, Patios, and Shed Bases

- Acts as a weed barrier and stabilization layer below ornamental stone, pavers, or compacted gravel.

- Prevents uneven settling of patios, backyard paths, and storage shed foundations.

- Offers easy drainage whilst preserving floor aesthetics and function.

4.5 Temporary Road Construction

- Provides quickly and fine subgrade reinforcement for get right of entry to roads at development websites or far off locations.

- Supports heavy equipment motion whilst minimizing soil disturbance and erosion.

- Can be without problems rolled out, anchored, and eliminated after task completion, making it best for temporary or seasonal use.

For reliable, long-lasting gravel driveway fabric, trust BPM Geosynthetics to deliver both quality and performance. Contact us today for a quote or technical consultation.