How to Choose Right Geotextile Landscape Fabric?

Global Market Landscape for Geotextile Landscape Fabric

The global market for Geotextile Landscape Fabric has expanded rapidly as landscaping, erosion control, and environmental engineering projects gain prominence across developed and emerging economies. Government-led green infrastructure programs, large-scale urban renewal, and the growing emphasis on soil stabilization have increased the demand for engineered fabrics that deliver consistent performance in varied climates and soil conditions.

Industry data indicates that the geosynthetics sector has surpassed USD 12 billion in annual output, with Geotextile Landscape Fabric representing one of the fastest-growing subsegments. Rising investments in sustainable land management, highway embankment protection, agriculture modernization, and commercial landscaping continue to fuel market growth. With cities prioritizing long-term ecological balance, high-performance geotextiles are becoming a standard requirement rather than an optional enhancement.

Key Market Trends Driving Adoption

Strong global adoption of Geotextile Landscape Fabric is influenced by structural changes in urban planning and environmental regulation. One of the major trends is the shift toward multi-functional geotextiles that integrate weed suppression, soil separation, filtration, and drainage capabilities within a single material.

Another significant trend is the demand for stronger UV-stabilized fabrics suitable for above-ground or semi-exposed installations. Manufacturers are expanding their product ranges to include higher GSM fabrics, nonwoven polypropylene mats, and permeable woven structures capable of supporting complex landscape designs.

Increased mechanization in modern agriculture has also highlighted the importance of durable landscape fabric to prevent soil erosion, maintain moisture, and optimize planting zones. Long-tail keywords such as “nonwoven landscape fabric,” “weed control geotextile,” and “heavy-duty garden ground cover” are becoming increasingly relevant in B2B procurement searches.

Technical Parameters Defining High-Quality Geotextile Landscape Fabric

Technical reliability is a defining factor in international procurement of Geotextile Landscape Fabric. Buyers frequently evaluate products based on the following parameters:

• Weight (GSM): common ranges are 70–200 GSM depending on filtration and load-bearing requirements.

• Tensile Strength: high-strength woven or needle-punched nonwoven structures typically achieve 6–20 kN/m.

• Permeability and Flow Rate: engineered pore sizes allow water to pass while controlling soil particle movement.

• UV Resistance: essential for projects with partial exposure to sunlight.

• Puncture Resistance: critical for long-term integrity in landscapes with sharp stones or mechanical impact.

These values help landscape architects and civil engineers determine appropriate usage scenarios such as weed control, soil stabilization, or sub-base reinforcement. Incorporating the main keyword **Geotextile Landscape Fabric** within technical documentation supports both SEO visibility and professional clarity.

Material Structure and Functional Design

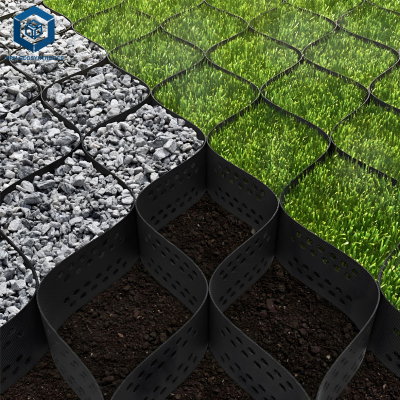

Geotextile Landscape Fabric is typically designed using either woven or nonwoven structures, each offering distinct advantages.

Nonwoven fabrics, produced through needle-punching or thermal bonding, excel in filtration and permeability, making them suitable for drainage layers, garden applications, and erosion control.

Woven fabrics provide superior tensile strength and structural separation, commonly used under roadways, patios, retaining walls, and paver bases.

The fabric’s pore structure is engineered to allow controlled water movement while preventing soil migration. These properties make Geotextile Landscape Fabric a versatile material in both soft landscaping and heavy-duty civil engineering projects.

Manufacturing Process and Quality Control

The manufacturing of Geotextile Landscape Fabric begins with high-grade polypropylene or polyester granules, which are melted and extruded into fibers. Nonwoven fabrics undergo needle-punching processes that entangle the fibers into a stable, dimensionally consistent mat. Woven fabrics are produced through high-speed looms capable of precise warp and weft alignment.

Strict quality control ensures uniform thickness, stable GSM, accurate tensile performance, and consistent filtration efficiency. Testing laboratories verify compliance with international geosynthetics standards such as ISO and ASTM. Continuous quality monitoring guarantees reliable performance during installation and long-term use.

Applications Across Landscaping, Agriculture, and Civil Engineering

Geotextile Landscape Fabric is widely used in commercial, municipal, and agricultural environments. Common applications include:

• Weed suppression in gardens, orchards, horticulture, and commercial plantations.

• Soil separation and reinforcement under pathways, patios, and parking areas.

• Drainage and filtration layers for retaining walls, ditches, and embankments.

• Erosion control along riverbanks, slopes, and construction zones.

• Agricultural moisture retention to support crop efficiency and reduce evaporation.

These applications demonstrate the versatility of Geotextile Landscape Fabric as a foundational material within modern environmental engineering and land development.

International Buyer Preferences and Procurement Insights

Global buyers prioritize reliability, ease of installation, and proven performance. Across Europe, North America, the Middle East, and Asia-Pacific, procurement teams consistently evaluate Geotextile Landscape Fabric based on:

• Strong and verifiable GSM specifications.

• Clear permeability and filtration performance data.

• Availability of customized roll widths and lengths to reduce on-site cutting and labor.

• Anti-UV and anti-aging enhancements for exposed applications.

• Competitive pricing backed by consistent production capability.

Common pain points include inconsistent quality from low-cost suppliers, insufficient laboratory testing data, slow delivery time, and lack of technical documentation. Addressing these issues is essential for maintaining global buyer confidence and ensuring long-term partnerships.

Future Outlook: Increasing Role of Geotextile Landscape Fabric in Sustainable Development

As global environmental regulations strengthen and cities accelerate green infrastructure projects, Geotextile Landscape Fabric is expected to play a critical role in sustainable landscape and construction practices. Advances in polymer engineering, improved manufacturing automation, and enhanced durability standards will continue to shape the competitive landscape.

We remain committed to supporting international contractors, distributors, and engineering firms with high-performance geotextile solutions that meet evolving global standards.

Conclusion: Supporting Modern Landscapes with Advanced Geotextile Solutions

Geotextile Landscape Fabric has become a core material in modern landscaping, agriculture, and infrastructure development. Its ability to reinforce soil, enhance drainage, suppress weeds, and improve project longevity makes it an essential choice for professionals worldwide.

We encourage international buyers to request detailed data sheets, product samples, and technical consultation to ensure the best material selection for upcoming projects. Expert support is available for specification development, installation guidance, and customized options.

FAQs

1. How do I choose the right GSM for Geotextile Landscape Fabric?

Lighter fabrics (70–100 GSM) are ideal for weed control, while higher GSM options (150–200 GSM) are recommended for soil separation, filtration, and structural reinforcement.

2. What is the difference between woven and nonwoven landscape fabric?

Woven fabrics offer higher tensile strength for load-bearing applications, whereas nonwoven fabrics provide superior drainage and filtration for general landscaping tasks.

3. Is Geotextile Landscape Fabric suitable for areas exposed to sunlight?

Yes. UV-stabilized materials are designed to withstand extended exposure and maintain long-term integrity when partially above ground.

4. Can I request customized sizes for large engineering projects?

Yes. Customized widths, lengths, and GSM specifications can be supplied to match project requirements and reduce installation labor.

For detailed quotations, technical sheets, or sample evaluation, please contact our engineering and sales team to begin your procurement process.