What is Geomembrane Welding Machine?

Choosing the proper tools is critical when it comes to developing durable, leak-proof geomembrane installations. Among the most essential equipment in geosynthetic engineering is the Geomembrane Welding Machine — a gadget specially designed to be a part of HDPE, LDPE, PVC, and different geomembrane sheets with precision and strength. These machines make sure seamless bonding that prevents leakage and ensures long-term overall performance in purposes such as landfills, ponds, reservoirs, and mining projects. Understanding how a geomembrane welding computer works — and why it things — is key to accomplishing dependable waterproofing effects in any civil or environmental engineering project.

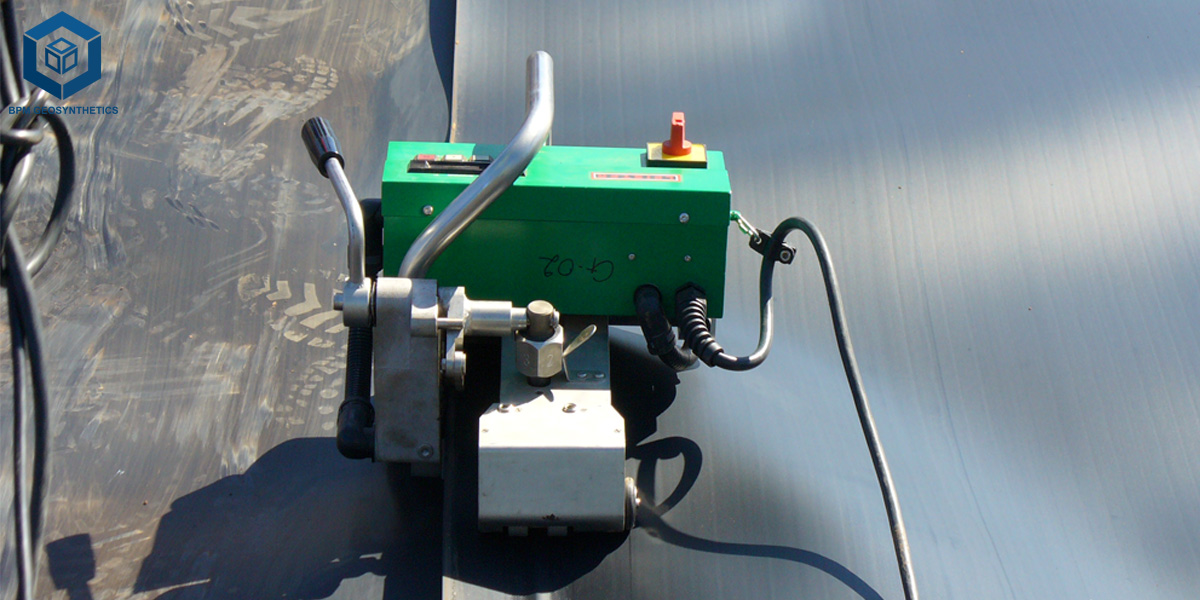

1. What is Geomembrane Welding Machine?

A geomembrane welding machine is a specialised system designed to create strong, durable, and leak - proof seams between overlapping sections of geomembrane liners. These machines make use of heat, pressure, or a aggregate of each to fuse the thermoplastic substances of the geomembrane liner together, forming a non-stop barrier vital for quite a number containment and environmental safety applications.

The integrity of the welded seam is paramount to the typical overall performance of the geomembrane lining system, stopping leakage and making sure the lengthy - time period effectiveness of the barrier. Geo membranes welding machines come in a number of sorts and configurations, every perfect to unique challenge requirements, geomembrane material, and web page conditions.

1.1 Geomembrane Welding Machine Key Components

1.1.1 Heating System: Hot wedge (300–450°C), warm air (400–600°C), or extrusion (500–600°C) mechanisms soften geomembranes for bonding.

1.1.2 Pressure Rollers: Apply 50–150 kN/m² to fuse molten layers, making sure uniform seams (12–40 mm wide).

1.1.3 Control Unit: Digital interfaces alter temperature (±2°C), velocity (0.5–10 m/min), and pressure, decreasing blunders through 20%, per Leister data.

1.1.4 Drive Mechanism: Motorized tracks or wheels keep constant speeds, enhancing seam pleasant by using 15%。

1.1.5 Cooling System: Air or water cooling solidifies seams in 5–10 seconds, per ASTM D6392.

2. How Does a Geomembrane Welding Machine Work?

2.1 Geomembrane Welding Machine Basic Principles of Operation

At its core, a geomembrane welding machine features with the aid of making use of warmness and stress to the overlapping edges of hdpe liner materials. This method melts the thermoplastic layers, permitting them to fuse collectively and structure a strong, impermeable seam.

2.2 Heat Application

The heating factor is a fundamental factor of the welding machine. Depending on the kind of machine, warmth can be utilized in various ways:

2.2.1 Hot Wedge Welding: This approach makes use of a heated wedge to soften the geomembrane liner material. The wedge is normally made of metallic and is heated to temperatures ranging from 300°C to 450°C. As the wedge strikes alongside the seam, it melts the material, developing a molten layer that can be fused together.

2.2.2 Hot Air Welding: In this method, a circulation of warm air is directed at the seam. The warm air, which can attain temperatures between 400°C and 600°C, softens the hdpe geomembrane material, making it pliable adequate to be joined. This technique is regularly used for thinner substances and in purposes the place flexibility is required.

2.2.3 Extrusion Welding: This method includes melting a plastic welding rod and extruding it into the seam. The extrusion system ensures that the molten fabric is evenly distributed, growing a robust bond between the geomembrane sheet layers.

2.3 Pressure Application

Once the material is heated and softened, strain is utilized to make certain a suitable bond. Pressure rollers are in many instances used to press the overlapping layers together. The stress utilized can vary from 50 kN/m² to a hundred and fifty kN/m², relying on the cloth and the required seam strength. The rollers make certain that the molten cloth is evenly disbursed and that the seam is free of voids or imperfections.

2.4 Control and Calibration

Modern hdpe membrane welding machines come geared up with superior manipulate structures that permit operators to exactly alter temperature, speed, and pressure. These controls are fundamental for accomplishing constant and dependable welds. Digital interfaces allow operators to set and display parameters with excessive accuracy, frequently inside a vary of ±2°C for temperature and ±0.1 m/min for speed. Proper calibration of these parameters is fundamental for the success of the welding process.

2.5 Geomembrane Welding Machine Process

The welding manner usually includes the following steps:

2.5.1 Preparation: The geomembrane sheets are laid out, and the edges to be welded are cleaned and inspected for any defects or debris. Proper alignment is quintessential to make sure a clean and fine weld.

2.5.2 Heating: The welding desktop is activated, and the heating thing starts to soften the geomembrane material. The operator video display units the temperature and adjusts it as essential to make sure best melting.

2.5.3 Welding: As the liner melts, the stress rollers cross alongside the seam, making use of regular strain to fuse the layers together. The operator keeps a regular pace to make certain uniformity in the weld.

2.5.4 Cooling: After the seam is welded, it is allowed to cool. Cooling can be accelerated the usage of air or water cooling systems, which assist solidify the seam shortly and limit the danger of defects.

2.5.5 Inspection: The closing step entails inspecting the seam for any signs and symptoms of weak point or imperfections. Non - unfavorable trying out methods, such as visible inspection or strain testing, are typically used to make certain the integrity of the weld.

3. What are the Different Types of Geomembrane Welding Machine Available?

3.1 Types of Geomembrane Welding Machines

3.1.1 Hot Wedge Welding Machines

Hot wedge welding machines are one of the most often used kinds of geomembrane welding equipment. They make use of a heated steel wedge to soften the high density polyethylene geomembrane material, permitting it to fuse together.

- Working Principle: The warm wedge, commonly heated to temperatures between 300°C and 450°C, is pressed in opposition to the overlapping edges of the geomembrane. As the wedge strikes alongside the seam, it melts the material, developing a molten layer that can be fused collectively below pressure.

- Advantages: This approach is surprisingly fantastic for thicker materials like excessive - density polyethylene (HDPE) and affords strong, long lasting seams. It is additionally appropriate for massive - scale initiatives due to its excessive welding pace and regular results.

3.1.2 Hot Air Welding Machine

Hot air welding machines use a flow of warm air to soften the geo membrane sheet material, making it pliable ample to be joined.

- Working Principle: The warm air, which can attain temperatures between 400°C and 600°C, is directed at the seam. The softened cloth is then pressed collectively the use of stress rollers to structure a robust bond.

- Advantages: This technique is tremendously fantastic for thinner substances and is regarded for its flexibility and ease of use. It is additionally portable, making it appropriate for on - website online repairs and smaller projects.

3.1.3 Extrusion Welding Machine

Extrusion welding machines use a plastic welding rod that is fed into a heated barrel, melted, and extruded into the seam.

- Working Principle: The extrusion method ensures that the molten material is evenly distributed, developing a sturdy bond between the geomembrana in hdpe layers. The extrusion head strikes alongside the seam, depositing the molten cloth and fusing it underneath pressure.

- Advantages: This technique is relatively nice for thick substances and presents strong, dependable seams. It is additionally appropriate for complicated tasks the place a excessive diploma of precision is required.

3.1.4 Automated Welding Systems

Automated welding structures are designed for excessive - quantity manufacturing environments and provide extended effectivity and consistency.

- Working Principle: These structures use superior manipulate devices to modify temperature, speed, and pressure, making sure uniform and dependable welds. They are regularly outfitted with a couple of welding heads and can deal with giant - scale tasks with ease.

- Advantages: Automated welding structures provide excessive - velocity welding, constant seam quality, and decreased labor costs. They are perfect for massive - scale containment structures and industrial applications.

3.1.5 Bi - Directional Welding Machines

Bi - directional welding machines are designed to weld in each directions, presenting multiplied flexibility and accuracy.

- Working Principle: These machines can go in each ahead and reverse directions, permitting for particular alignment and welding in tight or complicated layouts. They are outfitted with superior manage structures to make sure uniform and dependable welds.

- Advantages: Bi - directional welding machines provide improved accuracy and decreased turnaround time. They are best for modular structures and initiatives with complicated layouts.

3.2 How to Choose the Right Geomembrane Welding Machine?

When evaluating a hdpe geo membrane welding machine, it’s necessary to reflect onconsideration on the following factors:

- Material Type: HDPE, LLDPE, PVC, etc.

- Seam Strength Requirements: Tensile strength, peel resistance

- Project Scale & Location: In - area mobility vs. manufacturing facility automation

- Weld Speed: Required manufacturing output

- Environmental Conditions: Cold, wind, humidity

- Welding Parameters: Temperature, speed, and strain settings for most excellent seam quality.

4. Summary

A geomembrane welding machine is a essential device in contemporary geosynthetic applications. It provides precision, efficiency, and versatility for growing durable, impermeable seams.When selecting a hdpe geomembrane liner welding machine, it is indispensable to reflect onconsideration on elements such as material type, seam power requirements, mission scale and location, weld speed, environmental conditions, and welding parameters. The advantages of the usage of a geomembrane welding machine consist of excessive weld strength, price - effectiveness, environmental compliance, and versatility.

In conclusion, the Geomembrane Welding Machine is necessary for developing strong, leak-proof seams in geomembrane installations. It ensures long-term overall performance and reliability in ponds, landfills, and different waterproofing projects. For splendid substances and expert welding solutions, pick The Best Project Material Co., Ltd.(BPM Geosynthetics)— your depended on companion in long lasting geosynthetic products.