How to Choose Rigth Geotextile Suppliers Near Me ?

The search for "geotextile suppliers near me" is a common starting point for engineers and contractors, but the journey from that initial query to a successful, on-budget, and on-schedule project completion is fraught with critical decisions. The quality of geotextile—permeable fabrics used in soil separation, filtration, drainage, reinforcement, and protection—can make or break a civil engineering project. This article presents a comprehensive case study of the "Riverside Commerce Park" development, detailing the systematic process undertaken to select the ideal local geotextile supplier. Through this real-world example, we will illuminate the key steps, considerations, and pitfalls to avoid, transforming a simple procurement task into a strategic partnership.

1. Geotextile Suppliers Near Me Project Profile: The Riverside Commerce Park

1.1 Project Type

A 50-acre commercial and light-industrial park designed to accommodate warehouses, office spaces, and light manufacturing facilities. The project required durable infrastructure to support heavy vehicle traffic and long-term operational loads.

1.2 Key Challenge

The site consisted of variable, soft clay subgrades with a historically high water table, making it highly susceptible to differential settlement and soil instability. These conditions posed significant risks for the construction of access roads and building pads, including potential mud pumping, uneven surfaces, and long-term maintenance issues.

1.3 Geotextile Application

The project design specified the use of a high-strength non woven geotextile for two primary functions:

- Separation: To prevent the mixing of the soft clay subgrade with the granular base course, thereby maintaining the structural integrity, load-bearing capacity, and drainage performance of the road and pavement layers. This separation helps extend the lifespan of the infrastructure and reduces the need for costly repairs.

- Filtration/Drainage: To allow groundwater to pass through vertically while preventing soil particles from clogging the drainage system. This facilitates consolidation of the soft clay subgrade, improves surface stability, and ensures efficient long-term water management on the site.

1.4 Material Requirements

The project required 80,000 square yards of a specific non-woven geotextile with robust performance properties: Grab Tensile Strength of 120 lbs (ASTM D4632) for resisting stretching under load, Puncture Strength of 65 lbs (ASTM D4833) to withstand localized forces during construction, and a Permittivity of 1.0 sec⁻¹ (ASTM D4491) to ensure proper drainage and soil stabilization.

2. The Geotextile Suppliers Near Me Selection Process: A Four-Phase Approach

2.1 Internal Scoping and Long-List Creation

Before contacting any geotextile suppliers, the project team, led by the General Contractor "Summit Construction," developed a detailed Supplier Qualification Checklist. This internal document outlined the non-negotiable criteria:

- Certifications: Must be ISO 9001 certified.

- Testing: Must provide independent third-party test reports for the specified product.

- Location: Must be within a 200-mile radius to minimize freight costs and ensure rapid delivery.

- Experience: Must demonstrate proven experience in similar large-scale site development projects.

Using this checklist, the team created a "long-list" of five potential suppliers through:

- Online Searches: "Geo textile suppliers near me," "geosynthetic manufacturers in [Region]."

- Industry Referrals: Recommendations from the state's Department of Transportation (DOT) pre-approved vendor list and peer recommendations.

- Trade Associations: Reviewing members of the Geosynthetic Materials Association (GMA).

The long-list included two local manufacturers and three regional distributors.

2.2 The Request for Quotation (RFQ) and Initial Screening

A formal RFQ was sent to all five suppliers. It included:

- Detailed project specifications and geotextile property requirements.

- Required quantity (80,000 SY) and delivery timeline.

- A request for a line-item quote, including all taxes and freight.

- A request for supporting documents: ISO certificate, product data sheets, independent test reports, and at least two client references.

2.2.1 Initial Screening Results:

- Supplier A (Local Manufacturer): Responded within 24 hours with a comprehensive package. All test reports matched the specifications. Their quote was competitive.

- Supplier B (Regional Distributor): Provided a quote slightly lower than Supplier A but was slow to provide test reports. Upon receipt, the team noticed the puncture strength was marginally below the project's minimum requirement.

- Supplier C (Local Manufacturer): Their product exceeded the specifications but was 15% more expensive than Supplier A. They argued this was for a "premium" product with a higher safety factor.

- Supplier D & E (Regional Distributors): Supplier D failed to provide independent test reports, offering only in-house certifications. Supplier E's quote was surprisingly low, raising immediate red flags about product quality and origin.

Outcome: Supplier D and E were eliminated for non-compliance with the quality assurance criteria. Supplier B was placed on hold due to the non-conforming test data. Supplier A and C moved to the next phase.

2.3 Deep-Dive Evaluation and Technical Review

This phase was designed to assess the technical expertise and reliability of the finalists.

2.3.1 The Site Visit and Technical Meeting

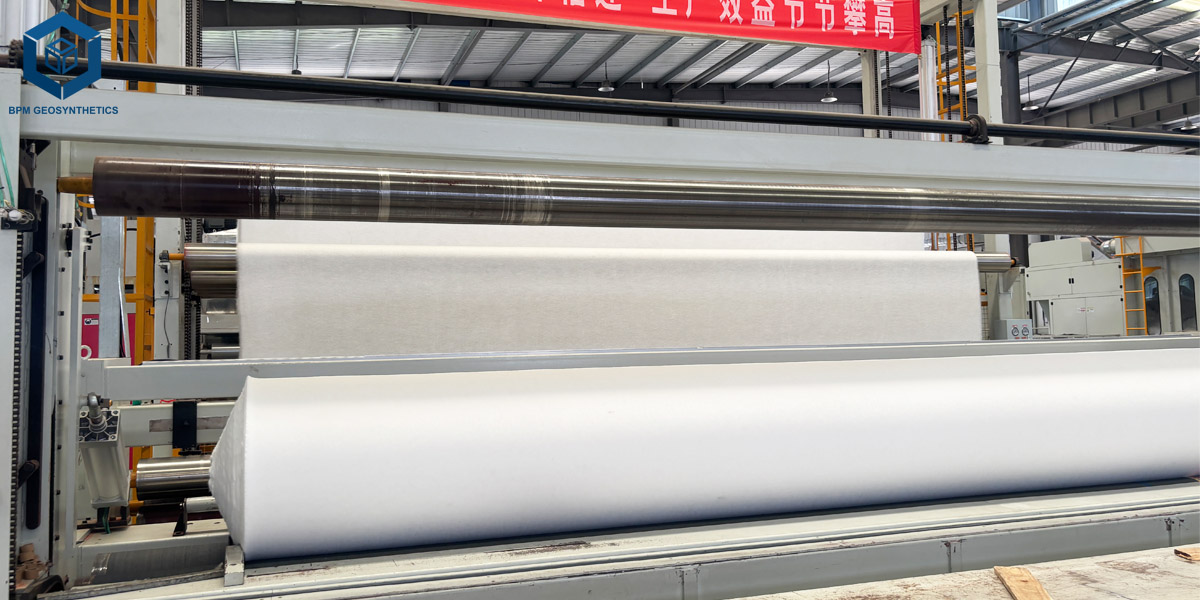

The project engineer and site superintendent visited fabric geotextileSupplier A's manufacturing facility. The visit was revealing:

They observed a modern, clean plant with rigorous quality control checks at every stage, from raw polypropylene input to the final rolled product.

The plant manager could explain how their needle-punching process achieved the required permittivity without compromising tensile strength.

They had a dedicated lab on-site for routine batch testing, backed by quarterly independent audits.

A subsequent conference call with geo non woven fabric Supplier C was also technically sound, but the team felt their "premium" product was over-specification for this project, leading to unnecessary cost.

2.3.2 Reference Checks

Summit Construction contacted the references provided by geo road fabric Supplier A. One reference was for a nearby highway expansion project with similar soil challenges. The feedback was glowing:

· "The geo fabric material consistently met spec. Every roll was clearly labeled with the roll number and property data, which made QA/QC on our end much easier."

· "When we had a last-minute schedule change and needed an extra 10,000 square yards delivered in 48 hours, they made it happen without any fuss. Their logistics team is excellent."

2.3.3 Value Engineering Discussion

During final negotiations, the project team posed a scenario to Supplier A: "A value engineering proposal suggests using a slightly lighter geo fabric under pavers. What is your professional opinion?"

Supplier A's technical lead responded not with a simple "yes" or "no," but with a detailed analysis:

· "Based on your soil report and the intended structural design, a reduction in puncture strength could risk premature failure during the dynamic loading of construction equipment. We would not recommend it. However, we have a different woven-nonwoven composite product that could potentially allow for a thinner base course, saving you on aggregate costs. We can run the numbers for you if you're interested."

This response demonstrated a deep understanding of the application beyond just selling a product. They were acting as a true engineering partner.

2.4 Final Selection and Onboarding

Supplier A was unanimously selected. While their initial price was not the absolute lowest, their total value proposition was superior:

- Assured Quality: Certified manufacturing and verifiable test data mitigated the risk of project failure.

- Technical Expertise: Their ability to troubleshoot and offer value-added advice was a significant asset.

- Logistical Reliability: Their local presence and proven track record of on-time delivery de-risked the project schedule.

- Cultural Fit: The team found them responsive, transparent, and easy to work with.

The contract was signed, including clear clauses for material certification, delivery schedules, and a protocol for handling any non-conforming materials.

3. Project Outcome and Lessons Learned

The Riverside Commerce Park project was completed on time and within budget. Post-construction monitoring showed no signs of subgrade failure or settlement issues on the access roads, a direct testament to the correct application of high-quality geo fabric for sale near me.

3.1 Key Lessons for Your Next Project:

- Pre-Qualify Rigorously: The initial checklist prevented wasted time with unqualified suppliers. Do not skip this step.

- Price is a Data Point, Not the Decider: The lowest bid (Supplier E) would have almost certainly led to catastrophic subgrade failure, resulting in massive cost overruns. The true cost of a geotextile includes its performance over the project's lifespan.

- Visit the Source: A site visit to a manufacturer's facility provides invaluable, unvarnished insight into their commitment to quality that brochures and websites cannot.

- Test Their Expertise: Pose real-world, challenging questions. The right supplier will engage in a technical dialogue, not just provide a sales pitch.

- Local Means More Than Proximity: A local supplier understands regional conditions (soils, climate) and can provide faster, more responsive service, which is crucial when dealing with unpredictable weather and tight construction schedules.

- Build a Partnership: The goal is to find a supplier you can trust for multiple projects. Supplier A's proactive approach to value engineering cemented a relationship that extended far beyond the Riverside project.

Conclusion

The search for "geotextile suppliers near me" for the Riverside Commerce Park evolved from a simple procurement task into a strategic, evidence-based selection process. It demonstrated that the right supplier is not merely a vendor of a commodity but a critical partner in ensuring geotechnical stability and project success. By meticulously evaluating quality, expertise, reliability, and total value, the project team mitigated significant risk and laid a strong foundation—both literally and figuratively—for a successful development. Let this case study be your guide, ensuring that your next geo drainage fabric purchase is a well-informed strategic decision, not just a transaction.

For reliable, high-performance geo fabric non woven and expert project support, The Best Project Material Co., Ltd.(BPM Geosynthetics)is your trusted partner worldwide.